How to unscrew a stuck bolt and how to lubricate it?

A threaded connection with a bolt and nut is considered the most common among all the types of fixation available. Plumbers, locksmiths, auto mechanics and other specialists in many fields of activity use this combination of parts. When the long-term operation of a particular mechanism requires repair or replacement of a failed part, one cannot do without untwisting the threaded connection. In this case, you can often encounter the problem of a stuck bolt.

Features of the problem

Most of the bolts and nuts used for fixing plumbing fixtures, bicycle or car parts are made from carbon steel. During operation, if dust or moisture gets in, in the presence of surface damage, it becomes very difficult to unscrew the damaged bolt.

The bolt can stick to the nut for some reason.

- Metal corrosion. Continuous exposure to water or snow on the bolt attachment point, such as a faucet, toilet foot, or car wheel, can cause rust on the bolt threads. It is not possible to unscrew the rusty bolt, the thread grooves of which are filled with oxidized growths, and it is not possible to unscrew the nut from such a thread with an ordinary wrench.

- Damaged bolt threads, its head or the integrity of the nut with a strong impact or repeated attempts to unscrew it, when tightening the bolt not along the thread with the use of strong impact. In this case, the risks on the bolt can be worn away, and further unscrewing of the damaged bolt can become a serious problem, especially in winter.

- Mutual penetration of metals of the main part and the connecting bolt. Diffusion of metals can occur due to exposure of the junction to high temperatures, such as the manifold of a car muffler. During the melting process, the metals of the part and the connecting elements form a monolith that is difficult to untwist.

When faced with the problem of a rusted or damaged bolt that must be unscrewed, it should be remembered that it is almost impossible to cope with this problem without special tools and devices.

To remove a toilet bowl, mixer, change a car wheel or fix a breakdown on a jack, use proven methods to get rid of stuck bolts. This will save time and prevent the head from breaking or breaking the bolt itself.

Unscrewing methods

There are several techniques and methods that can be used to loosen stuck bolts. You can perform these manipulations yourself at home. Before using this or that technique, it is necessary to thoroughly clean the joint from all dirt and, during a visual inspection of the attachment point, try to determine the type of bolt damage. Depending on the type of damage, you can resort to a mechanical, chemical or physical method of unscrewing it.

Mechanical

All methods can be classified as mechanical, which involve the use of great physical effort when trying to break a damaged connection. The mechanical method can only be used if the bolt is free from cracks, chips or bends.

The mechanical method involves several nuances.

- Using box wrenches instead of conventional wrenches. Since an ordinary open-end wrench is capable of affecting only 3 facets of the head when unscrewed, as a result of a strong impact, these faces can be erased, and the key will slide off. The box wrench grips all 6 corners of the bolt, which will help to apply more force for loosening.

- Using the extended key handle as a lever. Extending the wrench handle will help to apply a lot of pressure to the bolt so that rust that is preventing it from loosening will not be an obstacle.

But you can use the lever method only if the bolt head is not damaged, and its edges are not worn off.

- Application of short-term force effects on different points of a rusted joint part. You will need a hammer and a chisel, with the help of which you first need to knock out a notch on the head of the bolt, and then hit it with force in the direction of unscrewing. Such an effect is more powerful than when unscrewing with a wrench, and it will be possible to unscrew the stuck bolt much faster.

- Impact of a force of alternating direction on the bolt. To loosen the bolt using this method, you must first wrap it up, and then try to unscrew it. This manipulation can be repeated several times, since alternating movement in different directions will help free the thread from rust.

- Destruction of the rust layer by blows. It is necessary to apply blows to those areas of the bolt that are most affected by corrosion. The applied force will help remove the rust, but the damaged parts of the connection after such exposure will have to be replaced with new ones.

Physical

These methods of loosening rusted bolts are based on the physical properties of the materials used to make the fittings. There are the most common and commonly used methods.

- Heating of parts of the connecting pair. To warm up parts, use any source of heat or fire: a gas torch, blowtorch, soldering iron, construction hair dryer.

You can only warm up the nut, then its material will expand, and the gap between it and the stud will be increased. This will allow the entire connecting pair to be unscrewed more easily.

If you warm up the entire connecting structure, then under the influence of high temperatures, rust will begin to collapse and fall off from the connecting elements.

- Application of liquid to threads. When penetrating into the micro-holes between the nut and the bolt, liquids such as gasoline, kerosene, white spirit, turpentine can reduce friction between the bonded surfaces, which will provide easier unscrewing. The same property is possessed by means called "liquid key", which can be purchased at any car dealership.

Chemical

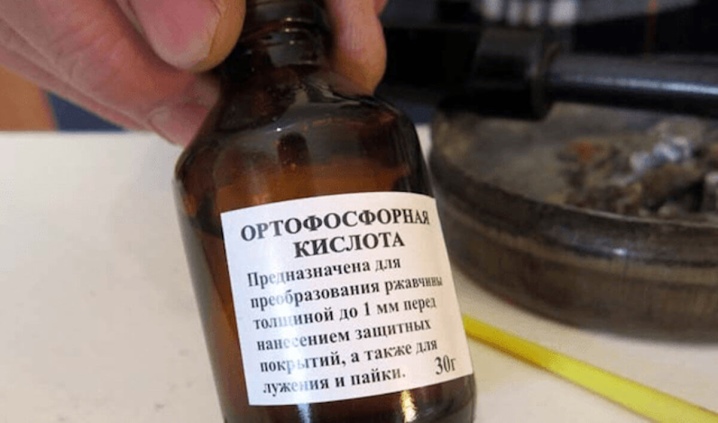

The action of chemical methods is based on the dissolution of a layer of old rust with the help of acids. Acids have the property that helps to destroy the corrosion layer:

- salt;

- sulfuric;

- lemon;

- orthophosphoric.

In order to dissolve the rust layer on the connecting pair, the joint must be treated with a few drops of reagent so that they can penetrate into the micro-holes on the bolt thread. If a large area is corroded, the bolt can be soaked in acid if possible.

The time required for acid exposure must be at least 24 hours. After its expiration, they first tap on the connection with a hammer so that large pieces of rust fall off, and then try to unscrew the nut with a wrench.

Since acids, when interacting with oxygen, release toxic vapor, all work must be carried out using protective equipment for the eyes, hands and respiratory organs.

Following the recommendations given, it will be much easier to unscrew the stuck connection. If none of the above methods succeeded in ripping off the stuck bolt, you can resort to cutting it off with a grinder or drilling it.But before applying these measures, it is necessary to weigh all the positive and negative aspects of them.

Prevention measures

Even if the stuck bolt could be pulled out, then after the manipulations, its thread, slot or head will most likely be damaged. The use of such a bolt will be impossible in the future. To preserve the original appearance of the fittings and to protect them from rust, care must be taken to protect the bolted connections even before they are installed on the part. To do this, you can use the recommendations.

- Before installing the connecting pair, lubricate the threads of the bolt and nuts with grease or machine oil. This lubricant forms a protective film on the metal surface and prevents corrosion.

- If the connection parts are used to fix the faucets in the kitchen or in the bathroom and are often forced to come into contact with water, then such a lubricant can eventually be washed off from their surface. In this case, it is advisable to carry out preventive inspection and lubrication of the joints at least once a year.

- To prevent connecting parts that are exposed to high temperatures from sticking to each other, it is necessary to use only connecting pairs made using special processing.

You can get acquainted with another way of unscrewing stuck bolts in the next video.

The comment was sent successfully.