All About Stainless Steel Bolts

Knowing everything about stainless steel bolts, including GOST stainless steel bolts, is very important for any novice craftsman. Therefore, attention should be paid to bolts M6, M8, M10 and other categories. It is equally important to understand the difference between wheel and anchor bolts, their materials, sizes, and features of choice.

Peculiarities

The term "stainless steel bolts" itself implies a wide range of metal products manufactured from stainless steel... Their appearance is simple - it is a cylindrical rod with a special thread. One edge of the structure is equipped with a special head. The main task of the bolt is to firmly fix the parts to be connected. Along with fixation in the internal volume of the part, fixation using a nut can also be carried out.

The detachable nature of bolted connections can be both an advantage and a disadvantage, depending on the specific situation. Various grades of steel are used for the production of bolts. Proven alloying components are added to it, increasing corrosion resistance and technical and operational parameters.

It is the use of stainless steel that guarantees the greatest reliability of the structure.

GOST 7798-70 previously applied to stainless bolts... Now it has been replaced by GOST R ISO 3506-1-2009. According to the current standard, tests for compliance with the declared characteristics are carried out at temperatures not lower than -15 and not higher than +25 degrees. A significant difference in mechanical parameters is allowed when the temperature goes beyond these limits. Corrosion resistance, oxidation rate and mechanical parameters under non-standard conditions must be agreed by the manufacturers and recipients.

The test procedures are carried out on special devices with automatically centering clamps. This prevents the effects of bending loads. The error in measuring the dimensions cannot exceed 0.05 mm. Yield strengths are set using pre-assembled screws and bolts. The procedure itself involves determining the degree of elongation of the bolt under axial pulling load.

Species overview

Stainless wheel bolts are widely used. As their name suggests, the main area of application is for fixing discs in car wheels. The difference between specific models can be expressed:

- in the size of the head;

- in the dimensions of the thread;

- in the features of the clamping surface.

It is the last aspect - the pressure surface - that is most important. The ability to firmly press the disc against the hub or the brake part depends on it, blocking the displacement. Most often, tapered elements with an angle of 60 degrees in front of the head are used. These designs can be fitted with a 0.13 cm headrest, although this is not required.

A number of bolts use an eccentric tolerance of 0.24 cm.

Such designs are suitable for mounting discs from a wide variety of cars. However, in this case, the dimensions of the hubs and discs should be limited to the very same 0.24 cm. To press the wheel stably, all surfaces are lubricated with a graphite-based compound. It is recommended to follow the manufacturer's instructions. For reliability, it is worth using bolts with "secret" heads.

Attention should be paid to anchor fasteners. Such products are mainly used in industrial and civil construction, in interior design. With the help of an anchor bolt, you can fix decorative items and household appliances in situations where ordinary nails, screws or screws do not help.They fit perfectly even into hard concrete. Also, this fastener is suitable for work on a brick, foam block, aerated block and a wall made of natural stone.

The necessary fixation is due to:

- friction force;

- the gluing effect of adhesives;

- the interaction of the spacer block with the passage walls.

The vast majority of anchors are to wedge or spacer type. Such solutions help to increase the external section of the working parts. At the same time, the intensity of friction increases. The special coating blocks the corrosive effect and prolongs the service life. The size of a specific product is determined in the marking.

Anchor bolt is considered a universal type of fastener. However, due to its rather high cost, it is impractical to use such structures in houses with wooden walls. With proper use, the following are guaranteed:

- increased resistance to stress;

- clear compliance with the task (since the range is very wide);

- the ability to increase the strength of an already assembled structure;

- ease of installation;

- long service life;

- excellent vibration resistance.

However, the disadvantages of the anchor bolt can be considered not only its high cost, but also the need for early drilling, and the need to choose fasteners according to the material being processed.

The anchor bolt can be fastened both mechanically and with an adhesive mixture. The second option is suitable for working in a fragile wall, which is made of aerated concrete. The wedge design, or a steel stud with the addition of a collet sleeve, implies an increase in the diameter during the twisting of the rod and its wedging inside the cavity. After inserting such an element into the hole, the nut will need to be tightened with an open-end wrench.

When the stud is screwed in, the cone bushing will touch the collet. At the same time, he himself will unclench and undergo wedging. This solution guarantees increased resistance to stress. But miracles do not happen - according to the laws of mechanics, stress is simply distributed over the entire contact area.

Therefore, it is unacceptable to screw such fasteners into cellular concrete.

On the other hand, a sleeve anchor with nut is ideal for this task.... Collet bolt with spacer - its further modernization. The bearing capacity is the same as that of the wedge product. The design is suitable for use in hollow brick and lightweight concrete. The only downside is the high price.

Hex bolt can be made for a variety of key sizes. Subtype - cap bolts with a recessed hexagon. Only the special Torx tool helps to work with them. Such fasteners are in demand in the automotive industry, but they are rarely used unnecessarily.

The end of the survey is appropriate on the hinged bolts. In addition to the main GOST, they must also comply with DIN 444. Such fasteners are suitable for cases when it is necessary to periodically dismantle (disassemble) the structure. Or for situations in which sticking of the bolt is critical.

This product is used in the body parts of all kinds of equipment.

Materials (edit)

A2

This type of steel is also called "food grade stainless steel". It is non-toxic and non-magnetic by default. This alloy is not hardened. Strength is increased by cold deformation. Foreign similarities - AISI 304, AISI 304L.

A4

This is a modification of A2 steel... It differs from food-grade austenitic alloy by the introduction of molybdenum. The addition of alloying metal is not less than 2% and not more than 3% (deviations are rare). The bolts obtained in this way work for a long time in the environment of oil and oil products, in sea water.

They do not corrode and are not poisonous.

Dimensions (edit)

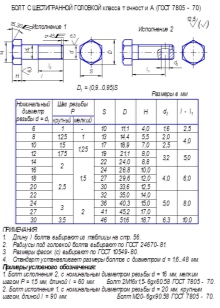

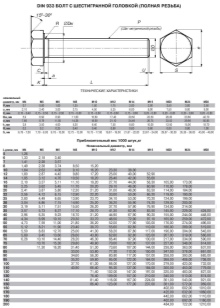

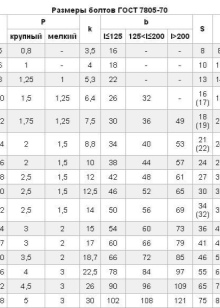

The bolt size is determined by the nominal cross-section. So, for M6, the length can vary from 12 to 50 mm; M6x40 is often used. M5 fasteners are usually performed in accordance with GOST 7805-70. In this case, the head height can reach 0.35 cm. The thread is made with a pitch of 0.8 mm (they are not made smaller).

The 140mm size can only have a 24mm threaded bolt.Its length ranges from 5 to 20 cm. Bolts are also quite widely demanded:

- M8 (head size 0.53 cm, rifling pitch from 1 to 1.25 mm);

- M10 (0.64 cm; 1.25 / 1.5 mm, respectively);

- M12 (always with a high DIN accuracy category);

- M16 (fine cuts 1.5 mm, coarse - 2 mm, length - from 3 to 12 cm).

How to choose?

It is not hard to understand that Choosing the right bolts is tricky. You will have to pay attention to the conditions of future use and the design load at the joint. At the same time, tensile strength and tearing strength are clearly distinguished. The required marking should be both in the accompanying documentation and on the head of the metal product itself. Additionally, it is customary to subdivide bolts into the following categories:

- engineering;

- furniture;

- road;

- ploughshare (agricultural);

- elevator (for conveyors of bulk materials).

And there are a number of highly specialized examples.

Most consumers choose traditional hex fasteners. But there may be products with a countersunk head. The semicircular head differs in that the "mustache" or the headrest will not allow to rotate in a normal position. Products for particularly difficult conditions of use are equipped with a press washer.

It dampens strong vibrations much more efficiently than simple washers.

You can learn how to polish a stainless steel furniture bolt in the video below.

The comment was sent successfully.