Features of anchor bolts with nuts and their sizes

Construction is a very important area in our life that everyone encounters. Due to the need for high-quality buildings and other architectural projects, this area is acquiring more and more new adaptations. One of them is an anchor bolt, which is a modification of a conventional bolt. In this article, we will focus on their subspecies - anchor bolts with a nut, features, advice on the selection and fastening of structures.

Description

Anchor bolts are a fairly new device used by modern builders. Its main and final goal is to secure heavy and large items. The bolt itself must be strong, and its fastening method must be reliable.

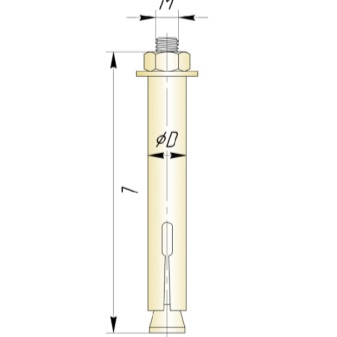

This product has a fairly simple appearance and a simple operating principle. The base of the bolt is a metal rod with the correct thread applied to it. All types and subspecies of bolts have such a part. A characteristic feature of the anchor bolts is the presence of a conical shape in the lower part of the rod. And also a kind of "shirt" is put on the thread, which performs a very interesting and important function. A nut is put on top of the thread.

So, let's figure out how an anchor bolt with a nut works. The "shirt", that is, the cylindrical sleeve, has slots along the main threaded rod. After a bolt is inserted into a specially cut hole, a nut is put on it. As the nut is tightened, that is, tightening it, the rod begins to creep upward, and its conical part, which is located below, begins to expand the sleeve. Thus, after a while, the cone-shaped part will almost completely go inside the sleeve and expand it by an amount equal to the diameter of the base of the cone. The extended bushing will hold the parts together in this way.

The purpose of the washer under the nut is also simple. It is needed so that during tightening the nut does not start to go inside the metal sleeve.

Species overview

In general, the anchor bolt itself with a nut is one of the varieties of construction anchor bolts. But this detail also has a subdivision into groups. In order to understand where each of the types is used, it is necessary to consider their characteristics.

So, at the moment there are two types of anchor bolts: conventional and double-expansion.

Regular

Anchor bolts with a nut, which have only one sleeve, are considered to be common. In another way, they are called sleeve anchors. In general, this option is the most common, which is why it began to be considered common. In some cases, such devices are also used in private construction. It should be noted that the principle of operation of conventional anchor bolts is very similar to the other type - wedge.

Such a bolt has two interrelated features. The first of these is the presence of only one holding sleeve, which leads to the use of the bolt only when the loads are not close to extreme. The second feature is that due to one bushing, the bolt is tightened more easily than its competitor subspecies.

It is important to clarify that bolts are made from different materials, therefore, when choosing this type of anchor bolts, one should take into account what they are made of.

Thus, this type is more suitable when it is necessary to contain high loads, but not extreme ones.

Double-spacer

Very similar to a conventional anchor bolt with a nut is another subspecies of such bolts - double-expansion bolts. In general, the principle of their work is the same. However, there is one important difference from which all of its other features follow. The difference is that there are two fixing sleeves instead of one.

This results in a stiffer and more reliable coupling of the two parts. The use of such bolts is recommended precisely when you need to connect two large and heavy parts. This is a definite plus of this species. However, there are also disadvantages, and one of them is tighter tightening of the bolt. And, indeed, it is much more difficult to pull two cones into the bushings instead of one.

With private or other small volume of construction, the use of double-expansion bolts is ineffective.

Dimensions and weight

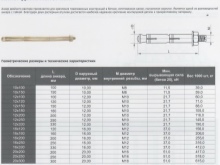

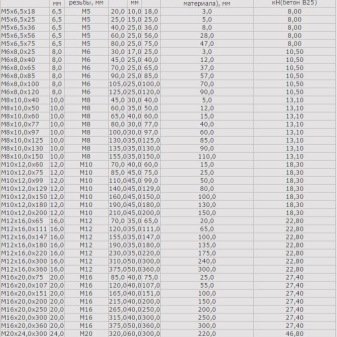

The choice of anchor bolts, like many other products, should be guided by various indicators prescribed in GOST. It is there that the parameters of the product are described: size, weight, level of maximum permissible load, and so on.

If you carefully consider the provisions of GOST, you can see that the smallest anchor bolt is a bolt with dimensions of 5x18 mm. However, despite this, it can withstand quite heavy loads if it is made of quality material.

The dimensions of the anchors are also very important. When choosing, you should be guided by the thickness and length recorded in the GOST.

By comparing the task to be performed with the dimensions of the anchors, you can choose the best option.

Here are some of the sizes that are used in the production of anchor bolts with nuts:

10x100, 12x100, 8x100, 10x97, 12x150, 20x300, 10x150, 10x77, 8x85, 12x60, 12x129, 10x250, 10x50, 10x60, 6x40, 10x200, 20x150, 6x60, 8x40, 12x200, 16x150, 10x10120, 16x200, 16x150, 10x10120, 16x50, 12x300, 10x80 mm.

And also the dimensions, indicating the thread diameter: M8x65, M8, M10, M8x35.

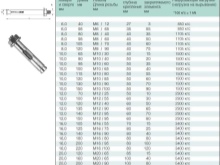

There are several concepts used in gost tables.

-

MPF Is the minimum pull-out force, which is measured in kilonewtons. It can be in the values 8, 10, 13, 18, 22, 27, 46.

-

TotAM - the thickness of the material to be bolted. This indicator varies greatly in different ranges - from the thinnest 5-6 mm to a thickness of 300 mm.

-

L - the length of the bolt, namely: the rod and the nuts on it. Length also has different meanings. Small anchors are available in lengths from 18 to 100 mm. Medium-sized bolts range from 100 to 200 mm, with the largest anchors reaching 360 mm in length.

-

H - depth.

-

TLotH - the length of the hole into which the anchor is to be inserted.

Judging by this table, we can say that the minimum length of anchors at the moment is 18 mm. This figure reaches its maximum at around 400 mm. The diameter of the sleeve cannot be less than 6.5 mm. At the same time, an interesting relationship can be traced - the longer the length of the anchor bolt, the larger its diameter.

And this is logical, because otherwise, with an increase in length, the strength of the anchor would decrease.

Selection Tips

In the modern world, when stores are overflowing with various goods, it is very important to know what exactly you need in order not to buy an unnecessary and useless thing. The following tips will help you understand the range of anchor bolts for a smarter purchase.

So, the first thing to look at is the length of the anchor. There are a lot of different models in length. The length should be chosen relative to the thickness of the material to be attached and the base material to which any part will be attached. The more these indicators, the longer the anchor should be purchased. However, you need to be careful with this indicator. Choosing too short will result in insufficient tightening force.

If you choose an anchor that is too long, then it can break through the base - wall, ceiling, and so on.

It is worth paying attention to another equally important aspect - compliance with the GOST adopted in the Russian Federation. This is very important, despite the statements of some not very good suppliers that their goods, although they do not comply with GOST, are still of high quality and reliable. In fact, no one can know exactly how things really are, but compliance with generally accepted standards helps to be confident in your purchase.

The material of the anchors is not decisive, however it is better to use higher quality models in important fixings. So, in those places where there is a risk of corrosion, it is worth purchasing special stainless steel anchors.

And, of course, the maximum load that the bolt can withstand. This is one of the decisive factors. But everything is not so simple here. Many experts advise to install those anchors, which have the maximum load “with a margin”. That is, if in the product passport there is exactly the value that you need, then such a bolt will not work. It is better to take a product that can withstand loads 4 times more.

This will ensure the safety and reliability of the fastening.

How to mount into the wall?

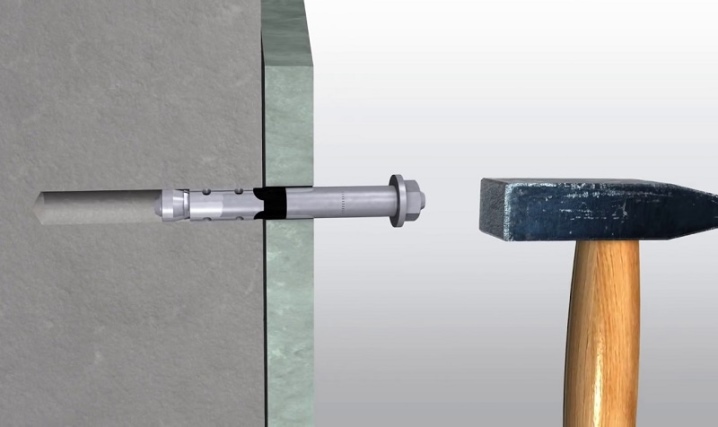

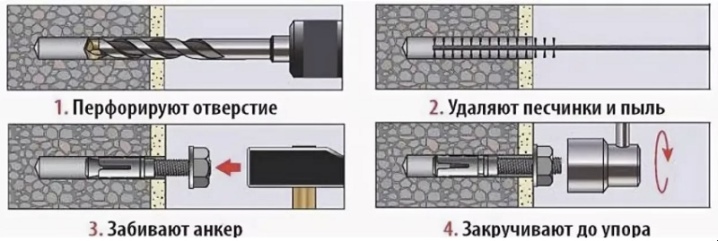

After the anchor bolt with nut is purchased, you can start using it. In order to understand how this process takes place, you can consider a specific case - fastening an anchor to a wall.

To properly install the bolt into the wall, you need to follow simple instructions. First of all, it is necessary to select and designate the place where the anchorage will be located. After that, you should use special tools in the form of a drill or drill and drill a hole. The diameter and length of the hole must be calculated depending on the parameters of the anchor and the attached part.

The diameter can be adjusted by selecting the correct drill and the depth manually while drilling.

The next stage of installation involves cleaning the hole. To do this, you can use a special compressed air gun or a regular household vacuum cleaner.

After that, it remains only to insert and tighten the anchor bolt itself, not forgetting about the attached part itself.

Anchor bolts with a nut are very common in the construction industry and are used not only in the construction of private houses, but also high-rise buildings. They have their own varieties, each of which has special properties.

Using advice on selection and installation, you can successfully use this device yourself.

The comment was sent successfully.