Dimensions, weight and volume of metal drums

At enterprises of the chemical, food, oil and other industries, containers are used in which it is convenient to store and transport various liquids and bulk substances of various kinds, including hazardous ones. These are usually metal barrels. In the household, water is most often stored in such containers for irrigating plants.

The assortment of metal barrels is large and varied. They differ in shape, color and technical parameters such as volume and weight. It is about the latter that will be discussed in this article.

Dimensions overview

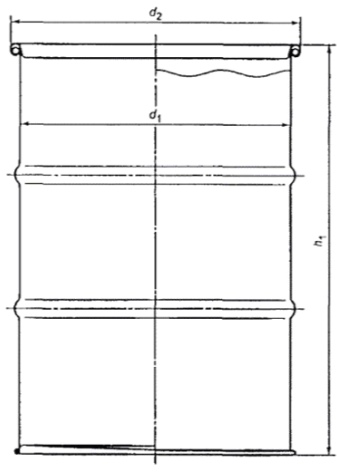

A metal barrel is a container that has a cylindrical shape. Cold-rolled steel is often used for their manufacture, therefore such products are characterized by high strength, durability and resistance to mechanical stress.

Such products are produced using contact welding: the body is connected with an airtight seam to the top and bottom covers. To increase the strength of the container, stiffeners are formed on the body, which divide it into three parts.

Since the demand for metal drums is quite high, they are produced in large quantities, of various sizes. They must necessarily comply with certain regulatory documents and requirements. The dimensions and volume are controlled by GOST 13950-91 “Welded and rolling steel barrels with corrugations on the body. Technical conditions ".

According to this standard, the following dimensions are allowed.

- The volume is 200, 250 and 300 liters. A two-hundred-liter barrel is considered standard, most of them are produced. The capacities of 250 and 300 liters refer to the overall ones. There are even less on sale, for example, 50, 100 liters.

- Height and diameter - these parameters directly depend on the volume. The height of a 200-liter barrel is 80 cm, and the inner diameter is 55 cm.The barrel with a volume of 300 liters is characterized by a height of 85 cm and an inner diameter of 60 m.

In addition to all of the above dimensions, there are others: the thickness of the bottom, cover and shell. The value of these parameters depends on the purpose of the container, as well as on the storage and transportation of which products it is intended for.

How much do the barrels weigh?

Since steel is used for the manufacture of such products, it can already be concluded that this is a rather weighty container. This technical characteristic directly depends on the volume. Let's see how the weight of an empty steel barrel depends on its capacity:

- the weight of a product with a volume of 200 liters varies from 19 kg to 26 kg;

- a container with a volume of 250 liters is characterized by a weight from 15 kg to 23 kg;

- the container with a volume of 300 liters is the heaviest and weighs from 29 kg to 32 kg.

It is not possible to say exactly how much a steel container fully filled with a substance or liquid weighs, it all depends on the nature and technical parameters of the material being transported.

Possible scope and definition

Volume is one of the main technical characteristics of steel and iron drums. It is this parameter that the consumer primarily pays attention to. Earlier in the article, we already talked about the fact that metal barrels are of different sizes, from 15 to 1000 liters. The volume of a metal barrel (this is indicated in GOST) is measured in m3.

To calculate this characteristic, a special calculator is most often used, a program that works on the basis of a formula. With its help, knowing certain parameters of both the container itself and the metal from which it is made, it is possible to calculate the volume.

To determine the volume of the container, you need to know:

- the type and subspecies of the material that was used in the process of manufacturing the container;

- the diameter of the barrel along the inner edge;

- wall thickness;

- container height;

- liquid level.

By calculation, you can find out such characteristics as the weight of the barrel, the outer surface area, the inner surface area, the volume of liquid in the barrel, and, of course, the volume of the container itself.

Since metal is used for the production of barrels, in practice, two methods of manufacturing a container are used - welded and seaming. Depending on the manufacturing method chosen, the design may vary. For example, barrels with removable and non-removable lids, hoop and others are now being made. Absolutely all dimensions depend on its design features.

More details on the dimensions of various types of metal barrels can be found by looking at the tables.

Tab. # 1

Technical parameters of a barrel with a capacity of 210-230 m³ with a non-removable lid.

|

Barrel capacity, m³ |

Inner diameter, cm |

Outside diameter, cm |

Height, cm |

|

212 |

56,6 |

58,5 |

89 |

|

216 |

57,2 |

58,5-59,6 |

87,8 |

|

230 |

57,2 |

59,6 |

93,2 |

Tab. # 2

Technical parameters of a barrel with a capacity of 85-200 m³ with a non-removable lid:

|

Item type |

Capacity, m³ |

Inner diameter, cm |

Outside diameter, cm |

Height, cm |

|

Rolled up barrel |

85 |

43,2-44,5 |

45,6-46,8 |

60 |

|

100 |

43,2-44,5 |

45,6-46,8 |

75 |

|

|

115 |

45,4 |

47,6 |

75,6 |

|

|

200 |

56,4 |

59,6 |

85 |

|

|

Welded barrel |

85 |

44,2 |

46,5 |

61 |

|

100 |

44,2 |

46,5 |

70 |

|

|

200 |

56 |

59 |

86 |

Tab. No. 3

Technical parameters of a barrel with a capacity of 15-62 m³ with a removable lid:

|

Capacity, m³ |

Inner diameter, cm |

Outside diameter, cm |

Height, cm |

|

15 |

25,4 |

27,8 |

35,6 |

|

20 |

27,9 – 30,5 |

30,5 – 32,5 |

33,2 – 40 |

|

25 |

27,9 – 30,5 |

30,5 – 32,5 |

39,2 – 49 |

|

30 |

27,9 – 30,5 |

30,5 – 32,5 |

48,4 – 58 |

|

50 |

35; 36; 38 |

38 – 40 |

47; 53; 68 |

|

60 |

35; 36; 38 |

38 – 40 |

58; 64; 68 |

|

62 |

35; 36; 38 |

38 – 40 |

59; 67; 71 |

For more detailed information on the technical parameters of metal barrels, the ratio of their dimensions, it is better to use GOST 13950-91. Also in this regulatory document, the dimensions of all parts and the permissible distances between them are clearly spelled out.

As you can see from the information in the tables, barrels are very different, and you can pick them up for absolutely any field of activity. For example, in the field of industry - oil, food or chemical, large enough containers are used for 10 cubic meters (1000 liters), 5 cubes (500 liters). In everyday life, steel containers of medium volume are most often used. The ideal option for home use is a metal barrel for 80, 100, 150, 200, 220 liters. The most commonly used are containers with a volume of 200, 300 liters (3 cubes).

The comment was sent successfully.