Liquid bitumen: technical characteristics and application

In various sectors of construction, due to a number of unique and high practical properties, a material such as liquid bitumen is used. It is used to facilitate the implementation of various technological processes in the construction of residential and industrial facilities, the creation of roof structures, the laying of pipelines, roads and various kinds of engineering communications.

This building material has excellent viscosity, ductility and good water-repellent properties. When penetrating into pores, as well as various cracks in coatings, it can become a binder, improve wear resistance and provide good adhesion.

What it is?

The material in question is an asphalt-like surface with rather unusual characteristics. It is used in a number of areas, but it will be especially indispensable in construction. Liquid bitumen is almost always used for paving roads, making roofing materials, and also for waterproofing various objects. It is used both in the construction of large industrial facilities and domestic ones.

There are two types of bitumen:

- natural;

- artificial.

The first is the product of natural oxidation of various petroleum substances. In its pure form, it practically does not exist. Most often, one has to see certain asphalt components - limestone and dolomite, impregnated with resinous compounds on a bitumen basis. They are crushed and, after being turned into powder, used for asphalt. Well, or bitumen can be extracted from the rocks.

The second type is the result of industrial-type processing. Such a process requires a method of vacuum distillation of tar or its forced oxidation using air purging. The first option is rarely used due to the fact that production is quite costly, and the second is always used.

Similar raw materials are also used:

- for the foundation;

- asphalt;

- waterproofing;

- concrete;

- wood;

- connecting pipe sections.

Specifications and labeling

Now let's say a little about the technical characteristics and labeling of this substance, which is most often sold in buckets, although sometimes it is found in cans. An increase in temperature for such a material becomes the reason for its softening, an increase in plasticity, which makes it possible to use bitumen mixtures. If we talk about the main characteristics that are important for the use of bitumen, it is worth mentioning the following:

- penetration determines the viscosity or density of the material;

- ductility - an indicator of the plasticity of a bitumen-based composition;

- thermal stability determines the temperature at which the bitumen masses soften and the substance transforms into a liquid state.

It should be said that the characteristics of the operational nature of this material are also determined by the brittleness temperature, when the first crack appears in the bitumen layer.

If we talk about such a thing as marking, then you should refer to GOST. According to him, bituminous compositions are divided into 3 categories depending on the class and viscosity:

- SG 40/70, 70/130, 130/200;

- MG 40/70, 70/130, 130/200;

- MHO 40/70, 70/130, 130/200.

There is also road bitumen, which is marked with the abbreviation BND. Today, 5 types of such a substance are used:

- 40/60;

- 60/90;

- 90/130;

- 130/200;

- 200/300.

The numbers indicate the viscosity of the raw material. Naturally, the consumption per 1 m2 of various types of such a composition will be different.

Also, the literal phrase denotes 2 classes of marking according to GOST as the structure is being created:

- slowly thickening;

- thickening at an average speed.

Now let's say a few words about each category.

Thickening at medium speed

This category of compositions with the designation SG is obtained by liquefying viscous-type bitumen for roads using oil products in liquid form. It is usually used for the construction of lightweight and permanent road surfaces, as well as for the formation of their foundations in any climatic road area of the country.

Slowly thickening

It is designated by the abbreviation MGO, it is obtained from slightly oxidized petroleum products or residual petroleum products or their compositions, which is necessary to obtain cold-type asphalt concrete and to create lightweight road surfaces, as well as foundations in road-climatic regions 2-5.

Where is it applied?

If we talk about the use of a bituminous composition, then depending on the goals that need to be achieved, the method of preparation and application of the composition will differ.

- In the case of use for the roof, pure bitumen without impurities is used - a technique that is hopelessly outdated, but still popular. Most often, the roofs of old houses and garages are covered with it by the simplest fill. Such material is cheap and the work is extremely simple. For roofing, the instruction for using bitumen is based on coating the roof surface with hot material. To make it flow better, furnace or diesel fuel, motor oils are usually added to it. Correctly pouring bitumen for waterproofing is required after a thorough assessment of the surface condition. In most types of waterproofing roof coatings, bitumen will be an intermediate layer between the wall and the impermeable canvas. To give better adhesion to the roofing material, pure bitumen should be used. The use of a pure substance has disadvantages, among which should be called low durability and low strength of the coating. Over time, under the influence of natural factors, the bitumen cracks, and the coating needs to be redone. To avoid this, polymers are added to the composition. It is best to use bitumen in combination with roofing felt for the roof. With the correct use of special mastics, such a coating will last a long time.

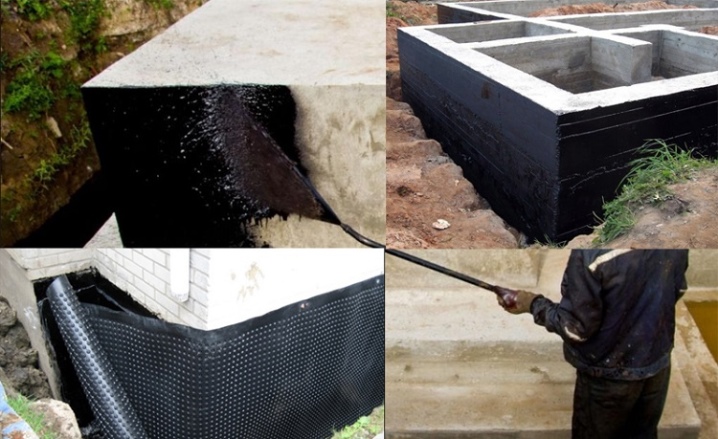

- Another area of application of the material in question is waterproofing for the foundation. Bitumen is often used to coat external foundation walls, and a rubber-bitumen-type cloth is applied on top - isol or brizol. If there is no serious groundwater pressure in the places where the foundation is located, and there are no earth movements, you can use the most common bitumen coating.

Despite the fact that the durability here is lower than that of bituminous mastics, the smeared defects will be closed for a long time from the effects of water.

- Formation of protective coatings on communication lines. Complex-type bitumen-based coatings are a universal solution for protecting pipes and other structures made of metal buried in the ground. The main waterproofing agent in this case will be various modifications of bitumen-based canvases. They are attached to mastic or bitumen, which are applied to a metal surface previously coated with a primer. Before applying the main layer that binds all the elements, it is required to cover the product with a primer. This is the name of diluted low-viscosity bitumen, which improves adhesion by filling the pores.

- Creation of asphalt-type pavements. It requires the use of the highest quality bituminous compounds that have maximum temperature and strength performance indicators.The downside of bitumen is the loss of its strength characteristics at high pressure. It is for this reason that the driving of trucks is prohibited on various types of tracks, especially in the summer. To improve the quality of the composition for the formation of asphalt, plasticizers are used, which have a whole range of positive characteristics.

- Pure bitumen is not suitable for wood processing., therefore, a number of special compositions based on it have been developed, in particular, bituminous mastic. Most often it is used as a waterproofing. In some cases, the mastic can act as a bonding layer when installing a wooden covering.

In the presence of low temperatures, bitumen becomes brittle, and at high temperatures it melts. The selection of this or that type of material will be determined by the loads and natural conditions of use. When laying highways where heavy vehicles drive, the appropriate bitumen is used. In addition, asphalt mix cannot do without gravel and sand.

The proportions of these substances depend on the coating requirements. The more sand and less gravel, the more smooth the surface will be.

How to use?

Let's try to figure out how to properly use liquid bitumen and apply it.

- To begin with, bitumen needs to be heated. Heating should be carried out in special installations, but more often the substance is heated in metal barrels on fire.

- The mixture will be ready at the moment when its surface is very smooth, almost glossy, without any signs of overheating. In no case should it be allowed, otherwise the coating will be fragile.

- After that, it is required to dilute the composition using a solvent. The best solution in this case would be diesel oil and diesel fuel. The first type of substance is not always easy to find, therefore diesel fuel is usually used. Bitumen must be diluted to a state from 30 to 70 to 50 to 50 with a solvent, depending on the required consistency and air temperature. If the volume of work is large, then the solvent is poured into the bitumen, if it is not large, then vice versa.

- If we talk about application, then after transferring the substance from the container, it will take only a minute and a half to level it. Before applying it, it is better to carry out the initial treatment of the surface where the composition will be applied using a primer. For leveling, you can use a roller, mop or brush.

It is not necessary to save the composition, and the joints must be coated well. And when sealing the roof, you should pay attention so that the new bitumen, after hardening, does not create difficulties for water to drain.

The comment was sent successfully.