Bitumen grade 90/10

Bitumen is one of the most famous and widely used building materials. The meaning of the word comes from the Latin bitumen ("mountain resin") and reflects the structure of the material, consisting of hydrocarbons and their derivatives, which are obtained as a result of the processing of oil and petroleum products.

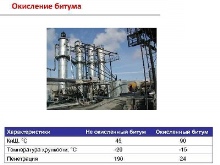

Production technology

There are natural and artificial bitumens. Artificial materials obtained as a result of chemical processing of petroleum products have found industrial application. The raw material for the production of BN 90/10 bitumen are tar from both AVT units (atmospheric vacuum tubes for primary oil refining) and from coking units, as well as asphalt and residual extract after separate purification.

At the moment, there are two technological processes for the production of bitumen, based on the oxidation of products of direct oil refining with asphalts and oil extracts by means of:

- oxidation;

- compounding.

The first method is preferred. Tar oxidation is a heterogeneous reaction between air and liquid. BN 90/10 is produced by bubbling - passing gas through a liquid layer in order to increase the content of asphalt-resinous substances. The process consists in blowing the feedstock with air heated to a temperature of about 250 degrees.

In this case, an oxidation reaction occurs between the hydrogen contained in the raw material and the oxygen in the air. The concentration of hydrogen decreases during the polymerization and thickening of the raw material to the consistency stipulated by GOST for bitumen BN 90/10. The reaction products, among other things, are: carbon dioxide, water vapor, distillation (its composition depends on the amount of volatile substances contained in the raw material).

As the outlet tank is filled with finished bitumen, a sample is taken for analysis. If the quality of the material meets the standards, the bitumen is cooled to 170 degrees, after which it is laid out in cardboard drums or paper bags, leaving to cool completely for 24-48 hours. The final stabilization process continues on dedicated concrete pads.

In summer, it lasts six days, in winter - up to four.

It should be noted that in the production of BN 90/10, the amount of waste is minimal - it is less than 1 percent. The gases generated by the oxidation are separated from the hydrocarbons, and a small amount of diesel fuel is usually sent to an incinerator or discharged into an industrial sewer.

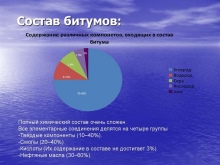

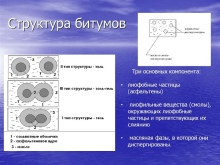

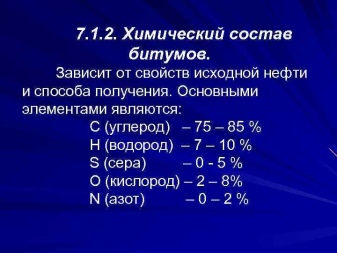

Bitumen has a complex composition, consisting of several phases:

- solid compounds that provide strength in the hardened state;

- petroleum oils that impart viscosity;

- stabilizers - resinous fractions responsible for adhesion.

Properties

BN 90/10 belongs to the group of artificial construction bitumen. Artificial bitumens are amorphous substances that do not have a melting point. They are resistant to acids and alkalis. A distinctive property is hydrophobicity. It is this property that plays a decisive role when using this material as waterproofing. In addition, bitumens have a number of other unique performance properties:

- easily mix with crushed stone fractions and sand due to the ability to soften and turn into a liquid state when heated;

- easily liquefied with solvents (diesel fuel, gasoline, etc.);

- have the ability to form artificial stone when mixed with mineral materials.

There are also some disadvantages:

- tendency to soften at elevated temperatures;

- fragility at low ambient temperatures;

- low mechanical properties (first of all, strength and elasticity);

- increased tendency to dry out (aging);

- not resistant to gasoline, turpentine, alcohol and other organic solvents.

Specifications

BN 90/10 includes:

- mineral impurities;

- cellulose;

- petroleum bitumen (percentage is 90).

BN 90/10 grade includes:

- conventional designation - BN ("petroleum bitumen");

- softening temperature - about 90 degrees;

- penetration depth of the needle (viscosity parameter in laboratory tests) - 10.

BN 90/10 are distinguished by good adhesion properties in relation to many materials: metal, wood, brick, natural stone. High consumer qualities make it possible to use it for high-quality waterproofing, which creates an additional layer of protection. Physical and mechanical parameters of the material are regulated by GOST 6617-76. Compared to similar materials (for example, BN 70/30), bitumen of the described brand is less prone to dripping, as a result of which it is widely used for application not only on horizontal, but also on vertical surfaces.

BN 90/10 is not only a functional, but also an economical building material: the average consumption is approximately 0.8-2.0 kg per square meter of the coated surface, depending on its type, structure and thickness of the applied coating. The density of the material is 1.5 g / cm3.

Retail BN 90/10 can be purchased in two types:

- in four-layer paper bags with silicone coating, the weight will be 40 kilograms;

- in briquettes, packed in 25 kg paper bags.

Scope of use

Due to its good water-repellent qualities, BN 90/10 bitumen is recognized as an excellent and inexpensive insulating material that protects against moisture. In construction, it is used to hydraulically isolate basements using coating. They use material for joints of reinforced concrete panels, foundations, for installation and restoration of the roof, for the formation of a concrete base for laying materials. In addition, cracks are poured with it.

This material is widely used in the installation and repair of pipelines, sewers, in the construction of tunnels, bridges, as well as in mine construction. It provides external waterproofing of building structures not only from stone, but also from metal, wood and other materials. BN 90/10 is a raw material for the manufacture of hydraulic insulation and mastic based on it.

In addition, it is part of roll roofing materials.

Application rules

BN 90/10 is used in a liquid state. To do this, it is heated in adapted containers (while ensuring that there is no direct contact with fire). To accelerate the melting, before immersing bitumen in a container, it should be crushed, splitting into parts. Bitumen is applied to the surface to be treated by means of brushes, rollers or paint brushes. In order to ensure reliable adhesion of bitumen to the surface, it is supposed to be thoroughly cleaned in advance from the previous layer of roofing, sand, dirt and other fractions.

GOST 6617-76 establishes the rules for the use of BN 90/10 bitumen:

- when used in the construction industry, the material is packed in steel or wooden barrels, plywood or cardboard drums and multilayer paper bags weighing up to 250 kilograms;

- retailers use similar plywood bags or drums;

- BN 90/10 bitumen may be transported both by road and on railway platforms, wagons and gondola cars (in addition, transportation over a distance of up to 500 km in specialized vehicles - autobitumen carriers is allowed).

Since bitumen is a combustible material (flash point - 220-300 degrees), then when working with it, you must follow the fire safety rules:

- use personal protective equipment and overalls;

- do not allow molten bitumen to come into contact with the skin;

- when a small volume of material is ignited, it should be extinguished with sand, a special fire extinguisher, felt mat or asbestos cloth;

- if a large amount of bitumen is ignited, use a foam jet or water.

The comment was sent successfully.