Bitumen grade 70/30: characteristics and application

It is impossible to imagine modern road construction without bitumen, waterproofing of buildings and structures from the aggressive effects of soil and atmospheric precipitation.

Specifications

Bitumen grade 70/30, being a petroleum building material, in the molten state is a liquid filler with binding and cementing properties. Without it, it is impossible to connect together gravel and sand, which are part of a full-fledged hot-laid asphalt.

Construction-oil bitumen is produced in compliance with the requirements of SNiP and GOST, known since the times of the USSR. The order of compliance with the technological properties and the staging of the process is determined by these two most important standards.

Bituminous filler is produced mainly of the following grades: petroleum bitumen (BN) 50/50, 70/30, 90/10.

The amount of bituminous resins and solvents may vary slightly, which ultimately affects their softening temperature - up to the point of complete melting.

The values of the characteristics of each composition are shown in the table.

|

Characteristic |

Marker |

Verification methods |

||

|

50/50 |

70/30 |

90/10 |

||

|

OKP 02 5624 |

OKP 02 5623 |

OKP 02 5622 |

||

|

Immersion of a needle at 25 ° C, with a diameter of 0.1 mm |

41-60 |

21-40 |

5-20 |

Based on GOST 11501-78 |

|

Softening in the form of a ring and a ball at a temperature, ° С |

50-60 |

70-80 |

90-105 |

In accordance with GOST 11506-73 |

|

Stretching at 25 ° С, not worse |

40 |

3,0 |

1,0 |

According to the standards of GOST 11505-75 |

|

What percentage will dissolve (not less) |

99,5 |

Guided by GOST 20739-75 |

||

|

Percentage weight change after melting |

0,5 |

According to the standards of GOST 18180-72 |

||

|

Flammable at a value in degrees Celsius |

230 |

240 |

In accordance with GOST 4333-87 |

|

|

How much water contains (molecular) |

Trace percentage (by weight) |

According to GOST 2477-65 |

||

Bituminous material that has not passed the test in accordance with GOSTs is not allowed for sale. Under the guise of bituminous building materials, fillers diluted with resins with completely different properties and indicators would be sold on the construction market.

Physicochemical properties

Bituminous building material with a 70/30 marker is a waterproof material with a dense structure and resistant to freezing at significant rates below zero Celsius. It is stable when heated in summer heat (under the rays of the sun), has a high degree of adhesion. Its purpose is hydro and chemical protection. This building material can be dissolved using most organic solvents - but in a heated state. It is chemically stable - under the action of most acids and all alkalis. So, completely bituminous material is soluble in benzene, gasoline, ethanol, carbon disulfide, trichloromethane and a number of other reagents. Aqueous chemical solutions - in the great majority - do not act on the bituminous layer.

BN 70/30 grade material melts easily - softening occurs already at +70. Solid fuel used for heating bituminous media is saved. And with the consumption of combustible materials, the time allotted for heating is also reduced.

Compared to the same brand BN-90/10, the composition with the 70/30 marker enables workers to bring it into an ideal condition for pouring it into the work area much faster. Buildings, structures and structures are sufficiently well protected from precipitation and ground moisture, without such a protective layer, undermining foundations and supporting structures.

The composition of BN-70/30 is aging as a result of a gradual change in its working properties to their values at which the layer of this material cracks, starting to pass moisture in a significant amount. The aging of the protective layer in a specific place is only spurred on by constant contact with the atmosphere and direct sunlight. The fact is that fractions resembling an oil-viscous medium gradually harden and polymerize. Some of them, on the contrary, decompose and erode. As a result, only a solid, crumbly cracked medium, remotely resembling sticky plastic, remains of the binder, viscous in consistency composition.

Instructions for use

The standardized consumption of the BN-70/30 composition for covering any surfaces is up to 2 kg / m2. The consumption of bitumen-based building materials is determined by the type and nature of the work performed, the thickness of the coating and the structure of the surface insulated from water. The composition is applied, for example, to the surface of a concrete foundation, with the possible addition of kerosene, gasoline, white spirit or nefras.

Spreading of an open fire molten under the influence of a source is possible only at facilities where there are no flammable and combustible building materials and structures. If the use of, for example, a gas burner is prohibited, solvent additives will come to the aid of the craftsmen.

It is possible to cover any surface of bitumen mastic that already contains the desired solvent.

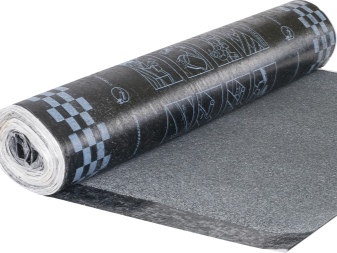

Flameless waterproofing material is more expensive - however, the work will be completed much faster, which will have a beneficial effect on the timely commissioning of the facility. Building materials with a bituminous composition are produced mainly in the form of rolls (roofing material), pieces or briquettes (solid, hardened consistency) or as sprayed media. The specific choice depends on the client.

Before starting painting work related to the application of the bitumen composition, the wall, foundation or floor is cleaned and washed from dust, dirt and debris, then dried thoroughly. Foreign objects and materials must be removed from the work area. All unnecessary, foreign media will worsen the quality of the applied waterproofing.

Before melting, the composition is taken out of the package, broken into pieces, placed in a metal tank - and heated, leaving the lid ajar. The volumetric filling of the selected container is three quarters. When the composition melts, it is stirred - this will completely melt the entire volume poured into the container, getting rid of air voids.

With the complete absence of unfused pieces and foam, this building material is ready for application to the prepared surface.

It is forbidden to heat bituminous building materials in wooden, plastic and cardboard containers.

The comment was sent successfully.