Rims for concrete mixer

Any large-scale construction is not complete without a concrete mixer. The crown design has gained great popularity among the people. In it, the mixing of the solution occurs under the force of gravity (due to gravity). Such a concrete mixer is simple and serves for a long time, but it is very important what material the toothed gear is made of, in other words, the crown of the concrete mixer. In this article, we will tell you in detail what crowns are and which one is better to choose.

Characteristic

Concrete mixers of the crown type are much cheaper than their counterparts with gearboxes, and primarily because they have a crown as a drive. Due to this design feature, in case of problems in this unit, it is not necessary to replace the complete drive mechanism - it is enough just to change the toothed gear (rim).

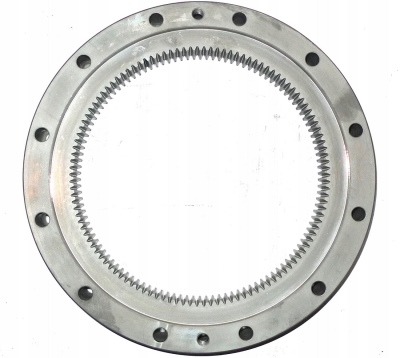

Due to its low coefficient of friction, it also gives durability to the drive gear. The crown ring itself does not go in one piece, but consists of several parts, which facilitates the process of its replacement - the drum is not disassembled during repair.

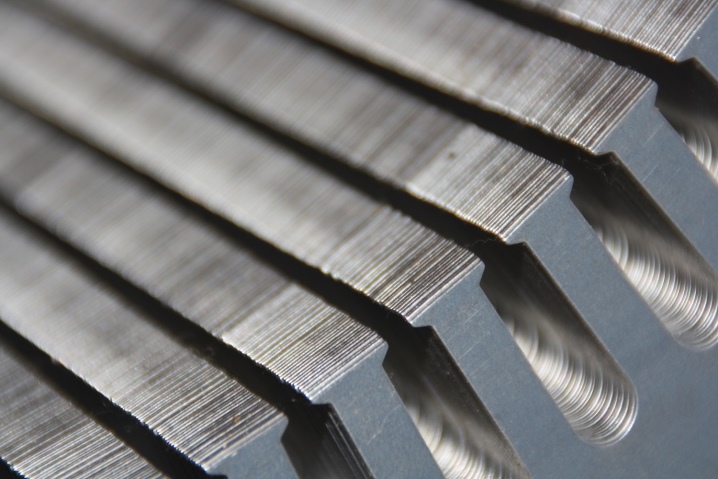

The element surrounds the drum of the concrete mixer, forming a closed ring with teeth. During rotation, the crown, meshing with the drive gear, forms a vibration effect: friction of the teeth of the crown crown of the gear occurs.

As a result of the intensive work of the construction apparatus, the parts can fail quite quickly. In addition, the crown is negatively affected by loads (more than 200 liters of solution), temperature drops, moisture ingress, its contamination, and blows are not excluded during the operation of the equipment.

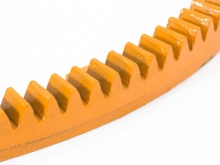

All this quickly destroys the product - that is why it is so important to pay attention to the material for making the crown. The crown gear is made of cast iron, steel, plastic and polyamide. Let's take a closer look at the types of crowns, identify the advantages and disadvantages of each of them.

Views

Cast iron crowns are most often found in concrete mixers, perhaps this is due to a rather easy production. A perforated toothed gear made of this material is obtained at a low cost. It does not take much time to cast cast iron into a mold, and after hardening, the product practically does not need to be adjusted.

But the biggest drawback of cast iron is fragility.... With frequent use, the cast iron crown can crack quickly, in addition, it emits a hum and vibrates during operation. Therefore, they purchase a concrete mixer with a product made of such a material for infrequent use and low loads.

Steel crowns are more durable than cast iron ones, but they are also more expensive. The process of their manufacture is more complicated, therefore the cost price is higher. But steel elements not only last longer - they work silently, which does not cause discomfort for builders.

Metal-crowned concrete mixers are ideal for those construction sites that require a continuous process of making mortars for exterior construction work and interior decoration. Such products can withstand heavy loads.

The cheapest crowns are plastic. The material itself is inexpensive, therefore the finished element is obtained at an affordable price. It, like its metal counterpart, does not make noise during operation, is not as fragile as its cast-iron counterpart, but also not as strong as a steel crown.

So buy a concrete mixer with a plastic product only for small amounts of work.

Along with steel, cast iron and plastic, the polyamide crown, created on the basis of a synthetic composition, has proven itself well. The product made of polyamide is resistant to various temperatures and its changes, quite durable: even abrasive particles are not afraid of it.

But it often does not have to be changed, even with intensive and prolonged use.... A polyamide crown can last twice as long as a steel crown. It has a smooth ride, it does not make noise during rotation. Well, lightness is another advantage of this element (7 times lighter than its steel counterpart).

Principle of operation

The principle of operation of girth concrete mixers is based on a belt-toothed transmission, that is, the engine drives the belt, from which the gear starts to move and then the crown - this is how the drum starts. There are two features of the operation of such concrete mixers: it is necessary to load the mixture and unload the ready-made solution only when the drum rotates.

And the second: it is not necessary to lubricate the place of contact between the crown and the drive gear. This will not be beneficial, but only harmful, since it will cause contamination of the elements, and this will lead to faster wear. The crown must be kept clean and cleaned every time you notice sticking. For this you need water and a brush.

Features of choice

Which crown is better? For a long time it was believed that it was cast iron or metal, but as they began to use plastic in the manufacture of crowns, they realized that this was the ideal option that would allow the technique to last longer.

However, when choosing a concrete mixer, you need to be guided by the amount of work and how often the equipment will be used. If the unit is needed on the farm only occasionally for any minor construction work, then it is quite possible to take it with a cast iron or with a plastic element.

Such a device will cost less than, for example, a steel one. But if there are heavy loads on the equipment, then, of course, it is better to take it with an iron (steel) crown. When working in winter conditions, a polyamide crown has proven itself well.

Before buying, read the instructions and study not only the parameters of the construction device, but also the moments of operation: what loads is the equipment intended for, what is the noise level that the unit emits, what are your financial capabilities.

The comment was sent successfully.