Selection and calculation of crushed stone for concrete

Crushed stone - especially granite, or primary, rocky, as it is otherwise called - is needed to strengthen the cement-sand mortar. There is more of it in concrete than the rest of the ingredients combined.

What is it needed for?

Professional construction workers are aware that it is impossible to make concrete without sand, cement and water in the required quantities. To obtain different strengths, proportions differing from each other are used. And yet, it is strictly forbidden to add other components, for example, clay or sawdust, if the ultimate strength is one of the main characteristics of the future structure due to a serious load.

The creation of particularly durable concrete involves the use of special additives and fillers. Not all of them make concrete better. The basic recipe for mixing concrete is unchanged. A change in the proportion of crushed stone, cement and sand will not leave unchanged the value of the permissible load on the floor that has hardened soon after pouring.

Crushed stone, unlike stones smooth on all sides, has an uneven surface - sometimes it is sufficiently cut in all directions, which will give the concrete additional strength.

This is achieved by significantly improving grip. The cheapness of crushed stone in comparison with cement is noticeable to the eye even for a user far from construction. This type of stone is characterized by significant strength and density.

Cement-sand mortar, into which some crushed rock was poured, demonstrates significantly lower creep. Together with the latter, the shrinkage of the cast - and hardened - structure is reduced. Concrete, in comparison with cement masonry, has a significantly lower tendency to cracking. The disadvantage of concrete is increased water permeability, density and specific gravity of a cubic meter of spent building material. Thoughtlessly pouring crushed stone into the cement mortar is not recommended.

When preparing, for example, concrete for pouring a foundation, it is unacceptable to pour coarse crushed stone into it, which has a high hardness. The experience of millions of builders, including self-builders, shows that the fraction of crushed stone should be relatively variable. The strength of such concrete will not suffer much, and you can save a little on cement without losing its characteristics.

Also, do not add only fine crushed stone to the composition. With a small amount of cement, the most durable composition can be obtained with stones of different sizes. Large stones bring the concrete closer to the structure of the wall, built primarily of them. Increasing the amount of cement - up to 1/2 in relation to sand - will make the concrete destructible only with a road bumper.

Concrete containing only crushed stone is suitable for hydraulic gates, dams, bridges, tunnels, artificial waterfalls.

An example of the latter is the Hoover Dam, which creates a metered flow of falling water that drives the power plant's turbines.

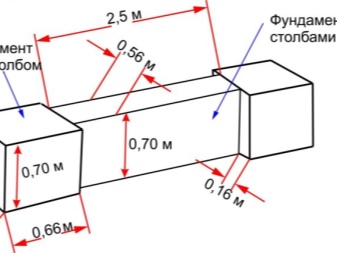

Supports and foundations are the most commonly used structures in the construction of structures and buildings. For example, for the construction of frame-monolithic high-rise buildings, reinforced concrete is used - the foundation, bearing supports and ceilings contain reinforcement that gives the buildings additional seismic resistance, and the concrete itself contains crushed stone, which is stones of different sizes.

Small gravel concrete is used for landscape design. Large-sized crushed stone is useful in road construction, including the construction of railroad embankments.

When adding crushed stone to concrete, it is necessary to thoroughly rinse it from dust and dirt: clay containing organic inclusions, due to its dusty structure, will significantly spoil the concrete in terms of strength. When buying crushed stone, assess its condition in accordance with GOST: foreign inclusions, according to its standards, will not exceed 2% by weight of building material. Having found a thick layer of dust, the crushed stone is washed, for example, in a concrete mixer. Washed crushed stone, like similarly treated sand, will provide maximum adhesion and resistance to significant loads in a relatively short time.

How much do you need for 1 cubic meter?

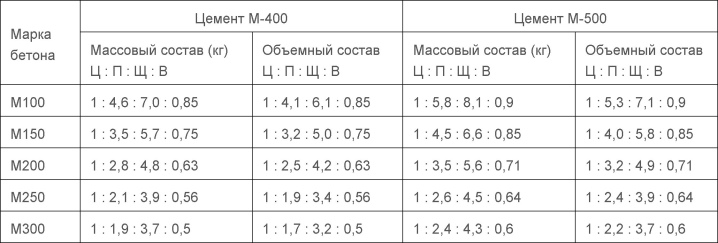

To help the master, the builder - recipes for concrete of various brands. Concrete marking is determined not only by the brand of cement, but also by its dose in the total volume. Water and sand vary in doses based on the size of the stones. For private construction, the following ratio is often used: a bucket of cement, two buckets of sand and three buckets of gravel - a dose of 1: 2: 3 will fit on the foundation. Accordingly, 1: 3: 3 is the ratio for less capital purposes, for example, the territory of the courtyard, where, say, cars enter, the courtyard sidewalk (on the street where passers-by scurry past the fence).

For footpaths, for example, in a park, gravel is used - without the need to roll it into concrete.

Another option is paving slabs made on the basis of fine-grained concrete building material. It includes crushed stone screening and polymer additives that increase its strength (elasticity for breaking the product).

For pedestrian areas and playgrounds where a hard surface is used, an insignificant deviation from a strict proportion will not play a fatal role for the strength of hardened concrete. Cracks will not appear earlier than they would in natural conditions.

For users who do not want to waste time on independent calculations, there is an online calculator on the website of any company supplying sand, crushed stone, cement and construction mixtures for various purposes.

The standard fraction of crushed stone is the size of a pebble of 2 cm - this value is most in demand in country-house construction. The average density of crushed stone is about 1400 kg / m3 - taking into account the air gaps between the stones, taking into account the small discrepancy of stones in the ready-made concrete, the weight of a cubic meter will be equal to 12 centners.

Sand, cement and water not evaporated from the concrete are designed to fill the void formed, without which the hardened concrete would quickly crumble into dust.

Further calculations showed that:

- 1200 kg of crushed stone is required,

- 220 liters of water are poured per cubic meter of standard (for non-capital supports) concrete layer;

- 250-300 kg of cement;

- more than 500 kg of sand.

Provided that there are no air bubbles in the newly poured concrete, the filling of the voids between the stones due to the cement mortar will be maximum. Over the next few hours from the moment the concrete is poured, the cement reacts with most (up to 90% by mass) of the water, forming a stony mass - it will supplement the substance with crushed stone, which was put into the concrete.

All materials should be checked before mixing - it is advisable to wash sand and crushed stone. If water is poured, the concrete will not acquire the required strength.

With a lack of water, it will become unnecessarily thick, not completely saturated with water during the kneading process - dry places are formed, which, like air gaps, reduce the strength of the poured structure.

Concrete grade M300, for example, requires consumption:

- 385 kg of cement grade M300;

- 1207 kg of crushed stone;

- 504 kg of sand;

- 215 liters of purified water.

The recalculation is carried out for the volume of concrete in 1 m3. Replacing sand with fillers like screening out the same rubble, brick and glass breakage, crushed used concrete, iron, sawdust, plaster knocked off the walls, broken gas blocks (after the demolition of old buildings) is highly discouraged.Sand is one of the cheapest building materials; it is not a problem to order just as many machines as is required for a full-scale construction (or reconstruction) at a specific facility. Quarry sand mining companies work directly with many private buyers.

Which one is better to choose?

For concrete requiring high-quality crushed stone, the buyer will form his own selection: the priority is the poured and hardened concrete of the same quality.

By faction

Crushed stone is the basis of concrete, in terms of the number in kilograms of building materials per cubic meter of pouring. Crushed stone significantly reduces the shrinkage of the hardened base: concrete without crushed stone, in which, for example, brick chips are used, will settle in the first 3 years so much that the structure, and with it the structure, will lose its original stability and become askew. Crushed stone with a fraction of less than 5 mm is not recommended to be added to concrete.

The strength of the hardened concrete depends not only on the thorough mixing of the main components, but also on the size of the crushed stone. Crushed inclusions 5-10 mm in size among the 20 mm pebbles are not considered a serious deviation from the required one. The secret of "different-sized" stones is that the fines are distributed among the large stones, falling into the voids.

These voids are not filled with either medium or larger ones: the uneven surfaces of the stones are cut and uneven.

Careful placement of concrete using vibration technology (shaking out the newly poured concrete) will not only bring out air bubbles, but also contribute to the settling of small pebbles between large ones, often small things go to the bottom.

By concrete brand

Having separately dealt with crushed stone, the optimal cement grade is selected for high-quality concrete. The higher it is (according to the marking serial number), the higher the quality of the concrete will be divorced and laid. The most optimal composition is considered Portland cement, which includes up to 80% calcium silicate. The more this salt, the more pliable the grout (and concrete) will become when pouring and leveling.

Calcium silicate makes a significant contribution to frost resistance: for Russia, low temperatures for six months - on average throughout the country - a natural phenomenon.

Construction involves the use of M500 cement, it is he who is universal. It is not recommended to use M200 and M300 cement for bearing supports and high-load (more than several tons) foundation.

Crushed stone makes a significant contribution to giving the hardened cement-containing construction mixture strength. Private and multi-storey construction involves the use of pebbles and crushed stones with a stone size of up to 40 mm.

Ideal storage of leftover cement is in plastic or glass sealed containers, completely dry. In this case, its shelf life can last up to 10 years. Whatever brand of cement is, you should not dilute it with recyclable materials from past construction and repairs, which usually comes to mind for a beginner.

Dust and dirt must not enter the concrete.

When preparing concrete with your own hands, use "different-sized" crushed stone. For example, to build a gazebo, to erect walls for a flower bed, cement of a "high" grade is not required: both M100 and M200 will do. Single-storey buildings, including outbuildings in the courtyard, require a cement grade of at least M250, but apartment buildings and low-rise buildings require cement at least M400.

It is not recommended to spend money on too "high" grade of cement: many people build houses not for 100, but, say, for 20 years. For a screed (non-black floor), cement grade M250 or M300 is suitable.

The comment was sent successfully.