All About Concrete Grinding

Concrete grinding is used for external (outdoors or in the yard) and internal (indoors) surfaces of the newly poured (applied) concrete layer. Both the floor or the platform as a whole, and specific areas, for example, reinforced concrete stairs, including steps and transitions, are subjected to grinding.

The need for a procedure

Grinding concrete improves not only its appearance, while ennobling the entire interior as a whole, but also significantly increases the parameters of the coating. This technique has many positive qualities:

-

ease of maintenance, application of other coatings on a concrete base;

-

increase in the operational period;

-

does not spoil the external and internal design of commercial buildings, buildings and sites;

-

concrete wears out less as a result of mechanical stress (for example, people do not slip on rough concrete, and wheeled vehicles do not skid);

-

increasing the mechanical strength of the base, hiding the seams and slowing down the cracking of the layer.

The sanded floor is resistant to all types of water-related damage. The overlying concrete layer becomes noticeably stronger. Aggressive chemicals such as acids, alcohols, alkalis and salts do not affect sanded concrete as destructively as unpolished substrates.

The meaning of concrete grinding is to remove a layer of small thickness, which has less strength... Close to the surface, a mortar with a high lime content accumulates on the concrete, which reduces the strength of the first few millimeters of the base thickness. On average, on the 4th day, a thin surface layer of the base is grinded.

The final grinding is carried out a month after the base is poured: the concrete will gain maximum strength, which means that grinding the coating will not damage it.

The sanded surface, although it has a smooth edge, has a high ability to absorb any paints, bitumen compositions and more... When the coating has aged (over tens of years), over the entire period of operation, numerous microcracks and chips have appeared in it, which cannot be eliminated, even if they are thoroughly filled with a layer of paint. Grinding the concrete allows this layer to be removed and the overall thickness of the substrate will naturally decrease.

Sanding of the old coating is carried out provided that it does not have undulating changes. Deviations from the strict horizontalness of the base are eliminated only when pouring a new screed.

If it is not the floor, but the wall that is being processed, then the task of the work being carried out is to ensure strict verticality. After leveling the walls, ceiling or floor, grinding the surface creates the appearance of a perfectly flat monolith.

Views

Depending on the purpose and method of execution, grinding is carried out dry and wet.

Dry

Dry sanding is considered to be the least productive method for cleaning floors or walls. It removes no more than 2 mm of concrete cover. Dry grinding is used for floors of standard strength, without special requirements for strengthening the foundation. The disadvantage is dust that settles for a long time due to the natural force of gravity, which will require the use of a respirator and a construction (technical) vacuum cleaner. Dry sanding - rough surface treatment: a floor or wall, treated with a dry method, becomes more rough.

Wet

Wet sanding is used for the treatment of extremely durable floors, for example, filled with concrete of the M450 brand. The advantage of the method is that a dusty plume does not rise in the air, which deteriorates visibility several times during operation. The base made of extra strong and hard decorative stone can also be ground. Wet sanding, in spite of water cooling, complicates the work due to the resulting dirt, which turns into dust combined with water. The cleanliness of grinding the base deteriorates; you can visually control the processing only by constantly washing the entire surface with an abundant amount of water.

Wet removal allows you to clean off the surface layer up to half a centimeter deep. After processing and cleaning, the floor must be dried.

What do you need for sanding?

For grinding the floor, it is imperative that you need a grinding diamond disc driven by a machine (drive)... As a rule, electric drives are used, in the simplest case the machine is a grinder. In other cases, an electric tool of increased productivity is used, working with abrasive wheels and steel brushes. The angle grinder attachment can be used both on a grinder and a drill. However, screwdrivers are unsuitable for this purpose - their revolutions, even on modern 2-3-speed models, are not enough: for smooth grinding, at least 3000 revolutions of the gear shaft per minute are required. The more durable the coating - for example, when it is built of stone - the more powerful and high-speed equipment must be.

It is not recommended to use conventional steel cutters and crowns for grinding concrete. The machine is necessarily equipped with a protective casing that prevents the dispersion of the smallest particles flying in all directions at a speed of tens of meters per second.

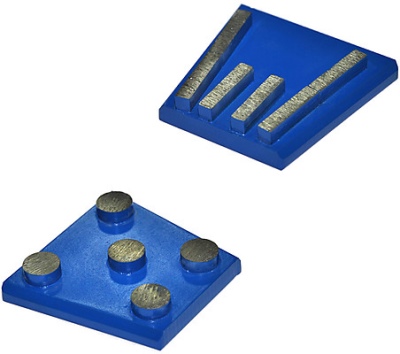

Processing of stone, brick, concrete is carried out using nozzles containing a diamond coating... As soon as it wears off, the layer of supporting steel is exposed, a crown, circle or disk is considered unsuitable for work on stone and concrete.

A vacuum cleaner must be connected to the dry grinding machine. The casing does not allow an excess amount of crumbs and dust to fly out of it during the time that the vacuum cleaner pipe has time to suck in most of the smallest particles of cleaned concrete or stone. The dust extractor starts up a little earlier than the grinding machine.

The attachments are fixed on the shaft of the gearbox or the motor; a casing is attached in the working area. If dry grinding is used, then use a construction vacuum cleaner - for him in the working air chamber, where the circle or disk rotates, an exhaust pipe is provided. The mechanism of the executive (grinding) drive is protected from dust, and step air filters are installed in the vacuum cleaner.

When using the wet method, instead of the exhaust pipe, water is supplied to the working chamber from the sprayer. The water machine (pump) has a sufficient operating pressure limit - up to 10 atmospheres. In the simplest case, a high-pressure washer is used, connected to a container (plastic barrel) with water or directly to the water supply (or well). The drive itself, whose force is used for grinding, can be equipped with an engine speed control system.

In hard-to-reach places, where the mosaic or traverse grinder did not reach, a grinder is used. It is used for polishing small areas, relatively small areas and rooms (up to 15 m2). Grinding discs are used in the form of a bowl-shaped disc - the central zone of the disc is recessed. They also use square pads - they are used for rough processing of irregularities that are noticeably raised above the main part of the disc. The double segment on the disk is used to remove the overlying layer. Boomerang-shaped onlays produce the final grinding stage.

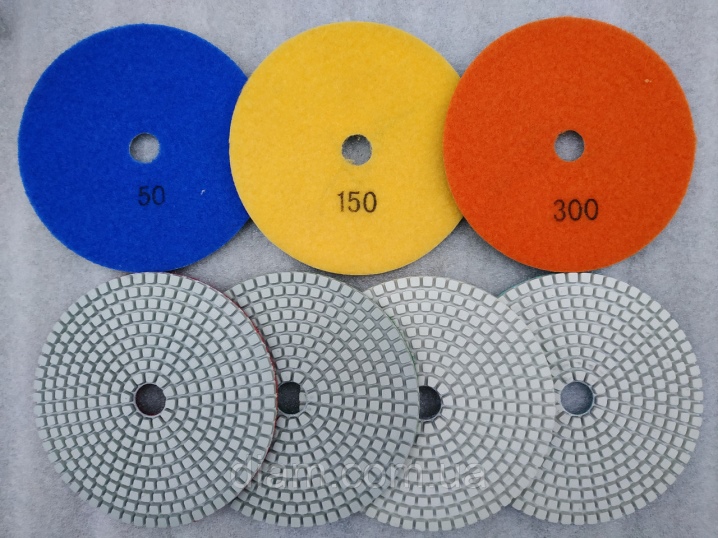

The outer working coating of the disc is diamond grit. The finer its fraction, the more accurate the grinding becomes.... Coarse chips are used for coarse grinding, small ones for polishing.

For concrete polishing, the so-called Frankfurt type of nozzles is used - in special cases. They are similar in shape to a trapezoid; the fraction of diamond chips is not the main determining factor in the fundamental design of such nozzles.

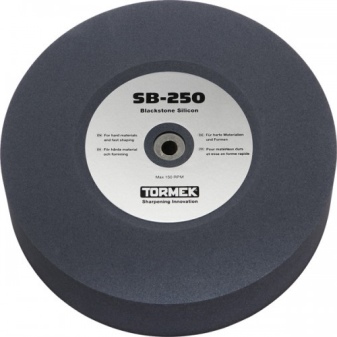

On some machines, for example, a number of CO models, a stone abrasive is used, the elements of which have a triangular shape. The smaller the granularity of the stone, the more precisely and smoother the concrete is cleaned. "Stones" are used on mosaic grinding machines. A flaw in this abrasive is a large amount of crushed waste. The engine speed of the CO is low - the concrete surface cleaned in this way looks rough. To reduce the consumption of cleaning materials, to increase the efficiency of execution of orders for concrete grinding, a separate impregnation is used - a polishing enhancer.

These substances work exclusively on a water basis, and their auxiliary action is akin to the effect given to concrete when poured with a plasticizer.

Reducing the consumption of abrasives, increasing the productivity of work is provided by polishing intensifiers. They look like special impregnations. They are added to the water when fed to the processing area.

Preparation

After pouring, be sure to wait until the concrete acquires most of its strength. To do this, it is periodically moistened with water - about 6 hours after the end of the pouring procedure: it should harden.

The preparation of an old concrete pavement, which for some reason was not sanded in a timely manner, is as follows.

-

All equipment and furniture are taken out of the room (or from the site). The work of people on the site ceases, all faces interfering with the repair of the coating are taken out of the territory.

-

Cleaning in progress: sweeping, possibly washing the floor or area... It should be clean around - this will allow the craftsmen to notice in the process of grinding all irregularities, bevels, in order to remove them, to make the floor horizontal (or vertical wall). If the floor or area has been washed, then to speed up drying, you can dry it with a fan, a construction hairdryer, or turn on the hood (if there is one). Drying the floor takes no more than an hour in summer than in the off-season due to the hot weather.

After making sure that the room and floor (or area outside) are ready, prepare the grinder and scrubbing attachments. For a drill, a hammer drill, an adapter for brushes and discs clamped by means of a chuck can be useful, which are fixed in a flange-threaded way.

If cracks are found on the floor or on the wall, then their "undercutting" is performed, followed by filling with fresh cement mortar. It is recommended to prepare a solution of at least M-300 for this purpose.

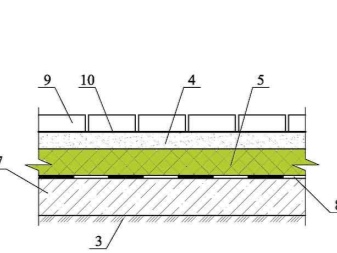

To prepare an old floor that does not contain a monolithic screed on the surface, perform the following work.

-

Remove the old floor covering.

-

Spread a layer of soil that is difficult to compress. Granite crushed stone and slag from blast-furnace production are used as working fillers.

-

Pour a 10 cm layer of low-grade concrete (M-100, M-150, but not the so-called lean concrete).

-

After hardening, install the beacons - they use profile-bent iron.

-

Saturate the concrete layer with binders.

-

Fill with a surface screed with solid fillers. The strength of this screed reaches a concrete grade of at least M-300.

Smooth base prepared. Its requirements meet all modern standards.

A significant contribution to the grinding of concrete without unpleasant consequences is made by pouring the base with fine gravel, sand concrete (concrete without large particles). Good and quick processing gives in to marble chips. To maximize the effect of the work carried out, adhere to a phased progress.

The condition of the newly poured or already existing coating is assessed. A laser level gauge installed on a horizontal, ideally even surface can be used to determine noticeably protruding places. It is switched on to the horizontal "measurement" mode and rotated in a circle (360 degrees). Individual areas can be checked with a bubble liquid level gauge.

Concrete can be tapped for voids: these places emit a loud and dull sound, a continuous zone without empty spaces almost does not sound at all. If voids are found, the concrete pavement is cut and the area is re-poured with new (sand) reinforced concrete. Gaps and technological seams are thoroughly closed. The presence of protruding reinforcement will require its removal with the help of a grinder - a disk, a circle, a cutter caught on a piece of reinforcement will break immediately, a sharp impact of the disk can damage the gearbox.

The unevenness of the concrete coating during grinding is removed with a forging disc (40 conventional units of grain size of the diamond coating). Small gaps can be filled with epoxy.

How to do sanding correctly?

Grinding a concrete surface with your own hands at home or in a garage is not so difficult a job as to call specialists. If the floor is large in area - for example, a production or store area is being polished, then the consumer (the owner of the building, area) is unlikely to do without a mosaic grinder. It only makes sense to process by hand when a living room in an apartment or in a small house in the country is subjected to grinding. Processing is carried out at increased speeds - about several thousand (up to 10,000) revolutions per minute. This rotation speed will be provided only by an electric motor. Gasoline units or diesel installations are not used for processing - the craftsmen would inhale these emissions, which would dramatically increase the harmfulness of such work.

It is not recommended to use discs with a grain size other than 40 conventional units. Crushed stone should not be pulled out of the concrete composition with which the base was poured. To improve the quality of work, a composition is applied to the coating that increases the strength of concrete by filling pores and microcracks in its surface layer. If, after processing, a defect occurs on the surface, then the detected defective points and places are filled with a cement mortar containing quartz sand.

A large amount of damage forces a completely new screed from a cement-quartz sand composition in two or three layers. This is the only way to get rid of the cracking of the surface of the old coating.

Obtaining a polished surface is guaranteed by using a disc in the course of work, the grain size of which is not less than 400. The ideal effect of the technology is achieved with a disc with a grain size of about 3000. To give the surface an almost glossy shine, it is impregnated with synthetic varnishes and paints containing polymers.

Manual grinding with a grinder is used with the same grinding disks that were chosen for industrial machines designed for a significant amount of work. Overheating of the grinder is not allowed: every 10-15 minutes of operation, the drive is stopped so that it cools down.

An attempt to use a low-power grinder, while reducing its speed, will lead to its rapid overheating (in less than a couple of minutes of operation) and burnout of the stator winding.

The carefully polished surface of the floor or walls delights the owner of the property for a long time with its almost perfect condition. It is ready for cosmetic repairs, as a result of its alteration, no improvement is needed. The floor in a country house or in an apartment, leveled in this way, is suitable for installing laminate or linoleum, while no bumpy neoplasms are visible after laying such a coating.

The comment was sent successfully.