All About Concrete Trowels

Concrete trowels are designed to eliminate excess moisture from the concrete surface, as well as to level out the smallest defects on the screeds. Due to the elimination of irregularities, the processing of concrete with a trowel allows you to compact concrete structures and make them stronger, remove cement serum. Trowels are actively used at all stages of construction work, especially when leveling various surfaces.

What it is?

A concrete trowel is a special tool used for leveling concrete mixtures on various surfaces. Thanks to the trowels, you can smooth the subfloor quickly and efficiently. The trowels are used both when pouring concrete and in the subsequent stages of construction work.

Ironers can be either professional or self-made. There are different types of these tools, which differ in both characteristics and power.

If a trowel is needed to perform easy work, and the specialist does not see the point in spending money on a professional device, the tool can be easily made by yourself.

Advantages and disadvantages

Hand trowels designed for concrete grouting have several tangible advantages:

-

ease of use;

-

the ability to carry out almost all work alone;

-

small expenses for the purchase of a tool, the ability to make the ironer yourself;

-

you don't need a lot of experience to work with such a tool.

The disadvantages include the conditional limited use - hand floats can only be used on a small area. In addition, the ability to maneuver when working with such a tool is severely limited.

Species overview

There are a huge number of options for concrete floats. Each of the varieties has its own characteristics that distinguish it from other models. The difference in tools can be in properties, operational functions, and type. Before choosing a tool, you should decide what tasks you will solve with the trowel, and how much work is expected.

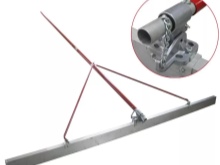

Scraper

Such trowels are used to remove whitish liquid from solidified cement, which is somewhat similar to milk. Thanks to this procedure, the operational characteristics of the structure are significantly increased - adhesion is enhanced before finishing work, as well as the upper layers are hardened. Using a trowel, you can fill in small depressions in the dried mortar, level out small bumps, check evenness in level. The features of these ironers are as follows:

-

the tool can be used in large areas;

-

the length of the handle reaches up to 6 m, and the possible width of the captured areas is up to 6 m;

-

strength and relatively low weight of the tool;

-

the ability to work at an angle, changing the slope;

-

a wide range of different blades.

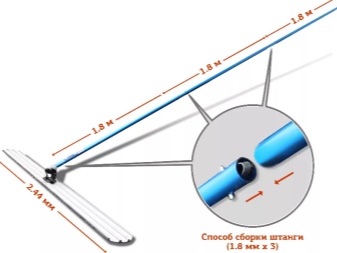

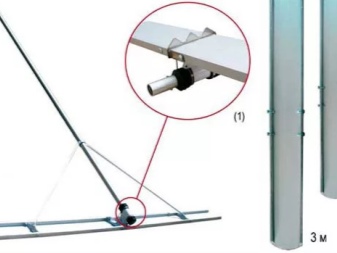

Duct

Channel trowels are often used to correct the surfaces of newly laid cement. Thanks to the tool, you can easily remove the slightest structural defects. Channel trowels have the following performance characteristics:

-

maximum width of coatings - up to 3 meters;

-

angle coordination is approximately 30 degrees;

-

the tool is made of aluminum or stainless steel;

-

the length of the bar is about 6 m.

Many tools come complete with a special attachment, with which you can divide the surface to be poured into sections. The use of a serrated nozzle allows you to get the job done faster, since expansion joints are formed at the same time as the subfloors are smoothed out.

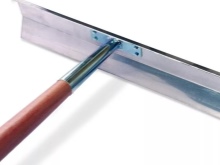

Manual rack and pinion

Such devices are used to treat small areas. The device has a mirrored sole made of aluminum alloy. At the end, the sole is rounded, the handle is attached to the sole. The length of the handle reaches 12 meters, and the blade can easily change the tilt level up to 60 degrees.

Made of wood and plastic

Plastic models are cheap and are often used for the treatment of concrete mortars. The models have a solid base to help remove even the smallest imperfections. Tool width - from 45 to 155 cm. These floats are often supplied with replaceable, height-adjustable handles.

Wooden trowels are most often used for finishing or building small spaces, as well as when it is necessary to iron small areas. Many models are disposable and quickly deteriorate in the process.

Trowels

The devices are ideal for leveling large areas such as asphalt concrete. The units are fully mechanized, the use of manual labor is minimal. Devices can be both electric (the most common option) and gasoline.

-

Electric appliances with one rotor - the polishing disc has a diameter of 600 to 1200 mm. Such machines are used indoors, when working with difficult areas. The kit includes an electric motor, a handle, a reducer, a disk, rolling wheels, a packet switch.

-

Gasoline models are used most often in open areas, work in closed rooms can only be carried out if the room provides for good ventilation. The devices have manual variations (equipped with a handle, models are used for sections of different difficulty levels), as well as self-propelled vehicles that are independently controlled and have two rotors.

Telescopic

A telescopic model is called a model in which rods and swivel mechanisms are provided. The handle can be rotated in different directions and extended to the required length. According to the types of surfaces to be treated, devices are angular, square or double, with pimpled inserts. The blade is made of magnesium and aluminum alloys.

Some models provide a vibration motor connection.

Selection Tips

Choosing a float should take into account several points.

-

The area of the plots in need of processing. If the length of the cement surfaces is less than 6 meters, then homemade units can be used. If the dimensions of the room exceed this figure, you should buy a ready-made tool equipped with a telescopic handle, the length of which reaches 12 m. For open areas of large diameter, it is better to rent or purchase a trowel.

-

Time constraints. If the work needs to be completed as quickly as possible, it is better to use mechanized units.

-

Monetary resources. Although such tools do not differ in high cost, to reduce the cost of work, you can make trowels yourself.

How to do it yourself?

It is quite simple to build a mop-ironer on your own; complicated calculations and drawings are not needed for this.

Materials used and required tools:

-

plane;

-

bars for fixing the board;

-

wide board for a blade up to 30 cm;

-

a piece of wood for a handle up to 50 mm wide;

-

jigsaw or ordinary saw;

-

screws for connecting parts of the trowel;

-

drill or standard screwdriver;

-

medium grit sandpaper;

-

moisture resistant composition or drying oil.

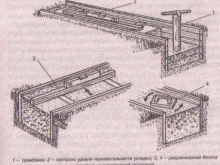

Let us examine the features of assembly and creation of ironers.

-

The sole is made of a board or bar with a length of 1 to 2 meters. It all depends on the area of the sites on which the work will be carried out.The board should not be more than 30 mm thick, as otherwise the float will be very heavy and will not work normally. We walk along the edges of the board with a jigsaw or a plane - the task is to round off the sharp ends. Surfaces that will interact with cement mortar must first be sanded with sandpaper. And also we go through the sandpaper along the edges of the trowel. There should be no gaps or roughness on the sole. After that, treatment with impregnation or moisture-resistant composition is necessary. These products will prevent the wood from absorbing moisture from the uncured concrete. Impregnating compounds are used according to the instructions. The trowel should dry well before it can be used. If there is no moisture resistant composition, you can cover the boards with linseed oil. It must be remembered that drying oil dries longer than factory impregnation. Instead of a board, you can use a sewer pipe.

-

For the handle, we take a small bar no more than 6 meters long. If the block is larger, one person will not be able to work with it. Round the edges of the bar with a plane. Using sandpaper we go over the irregularities, grind the part. For the trowel for working in small areas, you can use the handles left over from unusable shovels. Such handles already have a round shape, it will be convenient to hold on to them when working. The handle should be long and made of wood only. Plastic or iron holders are almost impossible to manually attach to a work board.

-

We attach the handle to the sole, observing an angle of 60 degrees.

-

The handle fastener should consist of rails and three bars. The parts are attached to the handle with screws. The connections are made as a spacer. The screws do not go behind the wooden blade of the trowel to prevent the sole from losing its smoothness. We look at how thick the sole is, and based on this, chooses the size of the screws.

-

Swivel joints can also be used when attaching the handle. In this case, the tool will move faster on different sides. We attach the hinges to the handle at an angle, so the handle will not dangle.

-

When the instrument is assembled, it is necessary to check its strength. To do this, place the trowel on any surface. Then we try to move the tool, and once again check the wooden blade for roughness.

-

If necessary, sand again - the surfaces should be as smooth as possible.

-

The movable trowel can be used as intended.

For an illustrative video, see below.

Terms of use

The correct use of the trowels is based on the principles described below.

-

Concrete trowels are used only after working with a vibrating tool, due to which the mixture becomes homogeneous.

-

The tool should only interact with the outer surface, without falling into the solution.

-

If the mixture is inherently excessively mobile, then adhesion will take place between the concrete and the trowel. If there is a lot of silica in the mixture, then this factor may increase. This must be taken into account when calculating the pressing force of the tools on the material. Excessive adhesion can change the height of the surface.

-

When working correctly, the tool first moves away from itself, and then moves in the opposite direction. Then the direction must be changed to perpendicular and the movement must be carried out at right angles to the already treated areas. If, after the initial finishing, irregularities remain on the surfaces, the procedure will have to be repeated.

-

When performing work, you should simulate a slight vibration, then the leveling of the mixture will be faster. Vibrating motion can be achieved by lightly shaking the trowel.

After leveling the concrete mortar, the trowel must be cleaned and placed in a dry place. Homemade products will not last long, since the boards will warp at some point. If the homemade tool is used immediately after the end of the first work, it can be stored.It is better to throw out a homemade float that will no longer be used.

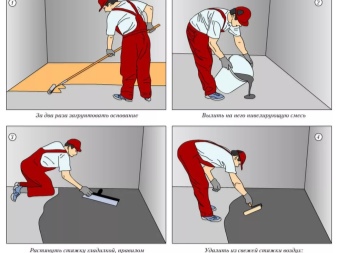

Before using the trowels, it is important to carry out preliminary work: moisten the concrete, fix it by standing and fill it with self-leveling compounds.

Do-it-yourself private builders often think about how to lay a smooth concrete floor at the same time as pouring the mixture. So that the result is excellent and time is not wasted.

Let's analyze the algorithm of actions for laying floors.

-

Along the length of the wall, at small intervals from each other (1000-1200 mm) and at a distance of about 200-250 mm from other walls, we place beacons. Beacons can be ordinary slats or metal profiles. Now you need to fix the beacons. This can be done with a small amount of solution. The constructions will serve for their intended purpose, and will also become guides when working with the rule. The rule will be a flat board or bar, you can also use a special tool made of aluminum.

-

The mortar is laid along the grips between the beacons. The poured concrete is gradually distributed and smoothed with a rule that is moved along the guides. The rule should be pulled to your side, creating a small vibration with your hand, shaking the instrument with light movements.

-

If everything worked out, then the final smoothing of the solution is carried out with a trowel.

You can smooth the surface after the final concrete placement, or you can do it as a rule. However, in both cases, special tools are used.

The comment was sent successfully.