Do-it-yourself gazebo with barbecue in the country: how to make a building?

A gazebo with barbecue is ideal for kebab lovers. Installing a barbecue inside the gazebo will allow you to feast on your favorite dish in any weather. The presence of such a design will allow you to have a great time with your family and friends at any time of the year.

Peculiarities

Before starting the construction of any building in the country with your own hands, you need to draw up a plan. It is better to arrange the gazebo in such a way that its entrance is located opposite the door of the house - this way it will be more convenient to take out and bring in dishes and food. Too close to the house or neighboring area is undesirable due to smoke and noisethat others may not like. However, it is also not worth placing the gazebo far from home - additional furniture may be required for the celebration, which will be inconvenient to drag over long distances.

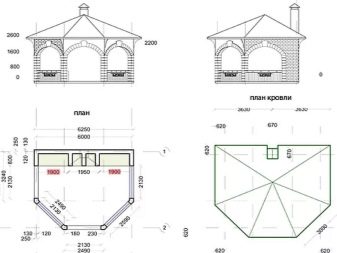

After deciding on the location and size of the canopy, we proceed directly to the construction. It is necessary to prepare in advance all the drawings, on which it is recommended to indicate the smallest details of the building, including dimensions. Even before the start of construction, it is worth carefully considering how the steps for the construction of the structure will look like step by step - this will help not to lose sight of anything.

Choosing the type of foundation

Even a structure as light as a gazebo needs a foundation.

The instruction on how to choose the type of foundation actually looks quite simple:

- If the gazebo is made of lightweight materials (cellular polycarbonate, metal rods, wood), it is enough to install piles to support the structure.

- The use of a large amount of brick or stone in construction requires pouring a concrete slab into the base.

- A strip foundation should be laid under a closed winter brick terrace.

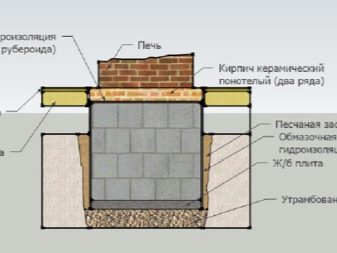

Regardless of the type of building chosen, you need to take care of a solid foundation for the furnace that can withstand its weight. This is especially true when using a strip or pile foundation.

To do this, in the place where the brazier will stand, it is necessary to dig a depression about 40 cm deep and fill it with sand. Then we pour gravel, ram. On top, we lay reinforcement with a thickness of 150-200 mm and fill it with concrete.

Installation of piles

We outline the size of the future gazebo and use a drill to drill 4 holes in the corners of the structure. We install pillars in the resulting grooves, pour crushed stone and sand, put the formwork. We install the reinforcement rods and fill them with concrete. If you buy an asbestos-cement pipe, you can reduce the cost of erecting a support post.

Reinforced concrete suburban piles can be installed even without digging depressions, but in this case, a special pile driving machine will be required.

After the concrete has hardened, a timber or a metal profile is laid on the piles. It turns out a square frame, which will serve as the basis for the construction of the building.

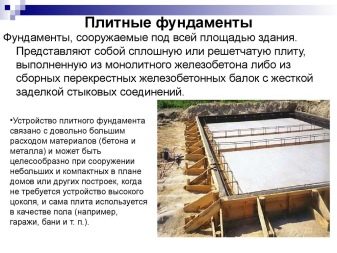

Installing a solid plate

For a foundation made of a solid concrete slab, it is necessary to remove a layer of soil over the entire area allotted for the future structure. It is advisable to add 300-400 mm on the sides for greater structural stability. Such an installation will prevent moisture and dirt from entering the foundation and will prevent corrosion and decay of materials.

After the pit is ready with a depth of 300-400 mm, fill the entire area with sand. The next layer is crushed stone. Then we install the reinforcement and formwork, rising above the ground by 150-200 mm. Pour concrete, making sure it is evenly distributed over the entire surface.

Installation of a tape-type foundation

The strip foundation is suitable for small, stationary closed-type buildings made of bricks or rounded logs.

First, we dig a trench 200-300 mm wide around the perimeter of the future gazebo. Then we tamp the earth inside. We fill up sand, gravel. We lay the reinforcement and formwork. Pour concrete inside the resulting structure. The ends of the reinforcement are left open - in the future, the arbor frame will be attached to them. After 3-4 days, after the concrete has completely hardened, the formwork can be dismantled.

After installing the foundation using concrete, it must be covered with a layer of waterproofing... Roofing material, polyethylene, bitumen mastic are used as materials. This is necessary so that the water settling on the concrete does not come into contact with other structural parts of the building.

Erection of wooden walls

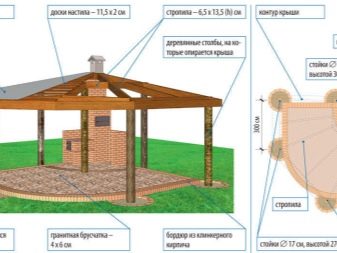

After installing the foundation, we proceed to the installation of the bearing racks. Wood is the most suitable material for a gazebo, because its cost is lower compared to other materials, and it will look more natural.

For racks, you should purchase a wooden beam 150 x 150 mm or rounded logs of the same section... We fasten them to the foundation with anchor bolts.

On the resulting strapping, we lay logs from a bar of 100 by 100 mm, which will serve as the basis for the floor. Now we install columns with a height of at least 250 cm. We strengthen the resulting structure with additional strapping at a height of 100-150 cm. For reinforcement, you can install additional diagonal bars inside the gazebo... We make the second harness at the top of the vertical posts. It is needed to fasten the rafters, which are the base of the roof.

Walls can be made of logs, boards, timber, sheathed with lattice. You can leave open one or all sides of the gazebo.

To install a barbecue inside such a gazebo, you should remember about fire safety. We cover all the details of the gazebo with a fire retardant, and put additional metal sheets around the location of the future barbecue.

To prevent wood from rotting, the gazebo should be impregnated with linseed oil, and then covered with oil paint and a layer of yacht varnish. This procedure is carried out annually on damaged areas.

Gazebo on a metal frame

The construction of such a gazebo will require a welding machine.

For strapping, you will need a metal profile with a section of 100 by 100 mm... It can be anchored or welded to the open ends of the reinforcement. We weld support racks to them. We strengthen them along the bases at the top and bottom of the structure with metal corners. Just as in a wooden structure, we put an additional bundle and the base of the roof.

After welding, the entire structure must be primed and painted - this will prevent the appearance of rust on the metal.

To obtain a closed winter gazebo, the frame is sheathed from the inside with plywood or wooden beams, clapboard, and outside we attach siding panels or polycarbonate. An additional mineral wool pad can be used as insulation. It is better to place all combustible materials away from the barbecue and be sure to treat with fireproof impregnations... The floor in such a gazebo, erected on a concrete slab, will be decorated with tiles.

Arbor made of brick or stone

A stone gazebo requires a lot of effort, time and money during the construction, but it does not require additional costs for annual processing, and the service life of such a structure is several times higher than others.

After the construction of the strip foundation, we lay the waterproofing. Now we begin to erect pillars or walls of brickwork.There are many options here. For an open gazebo, it will be enough to install the pillars, leading them under the roof... Someone would prefer to completely lay out one wall from the side of the barbecue and the cutting table.

A closed gazebo can look like a complete home.

We build a roof

The roof in the gazebo is primarily necessary for protection from rain and the scorching sun. It can be gable, hip, dome, hipped, spherical, single-pitch, gable, ridge. At the same time, it should be light and withstand the load from the snow lying on top. In the roof of the gazebo with barbecue, you should consider an additional hole for installing a chimney. Thanks to the installation of a metal umbrella over the chimney, you can cook a barbecue in any weather.

The following coatings are traditionally used as material for roof cladding:

- metal profile sheets;

- flexible shingles;

- sheet metal;

- galvanized sheets.

In a gazebo with a small area, it is better to fasten the roof parts on the ground, and then install them up already assembled, but this is possible only if there is a lift. Otherwise, all work is carried out at a height.

We make a brazier

The simplest grill is a portable one made of sheet iron. You can make it yourself or to order. This option is perfect for placement in a finished gazebo.

It is advisable to install a stationary brick brazier before laying floors and erecting walls.

A small brazier can be laid out without using a cement-sand mortar. To do this, first we put refractory bricks tightly to each other. Then we make sides on the sides, placing the bricks either flat or sideways. Such a model is convenient in that it is easy to disassemble and assemble, increase or decrease the height, it is easily cleaned of ash.

A separate foundation will need to be made for the oven. Laying the bricks should be done immediately after the concrete has completely hardened, preferably at the same time as the walls of the gazebo are erected. The chimney of such a barbecue can become an additional support column. A sheet of iron is laid flush with the floor, then an ash pan and a firebox are made. Thick sheets of metal are suitable for the firebox.

Particular attention should be paid to the installation of the chimney, dampers and hoods, because their incorrect location can lead to a lack of draft.

For information on how to build a gazebo with your own hands, see the next video.

The comment was sent successfully.