Brick stoves in a gazebo: features of creation

A brick stove in a gazebo is a convenient device for cooking and not only. In addition to the variety of dishes available for cooking, it will extend the outdoor seasons thanks to the transferred heat. A do-it-yourself brick stove is a durable and practical design. Consider the features of creating these devices.

Peculiarities

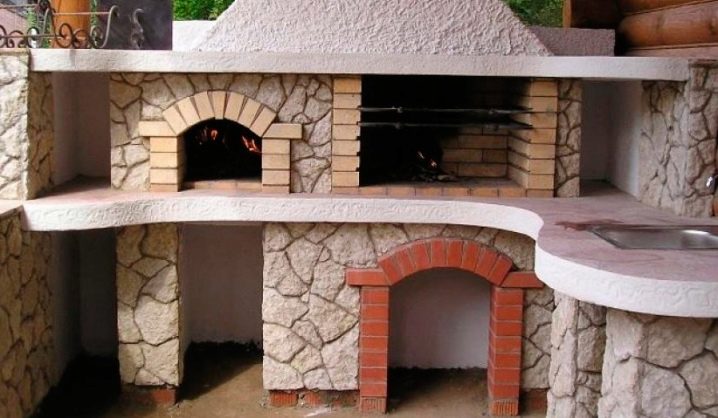

A luxurious brick oven with a barbecue area, a hob, and other attributes is a complex device that is not easy to build without experience in the construction industry. The main feature of a brick stove is the mandatory presence of a concrete foundation. If the gazebo is made in a light version and has a plank floor, you should get by with a portable barbecue. If it is decided to build a stone oven, it is worthwhile to understand in more detail the design features.

A do-it-yourself outdoor stove must meet a number of requirements. Let's consider the main criteria.

Security

Do not let the parts of the stove come into contact with objects that can easily ignite. Special screens must be used as protection. This feature is worth paying attention to if the stove is located in a wooden gazebo.

Moisture resistance and frost resistance

The stove in the gazebo is used during the warm season, but the structure will be located in the yard all the time. Therefore, building materials should not absorb moisture. The accumulated liquid, freezing, will break the brick, which may cause cracks, and the stove itself will begin to collapse.

The correct type of material must be used for the construction. They must be fireproof.

Heating temperature

Even in extreme heat inside, the outside of the device should not heat up. Hot surfaces can cause burns if accidentally touched. This can be eliminated by special surface finishing. Tile and stone are suitable as non-combustible cladding.

Environmental friendliness

The material chosen for an outdoor stationary stove should not contain harmful components that, when heated, will spread, harming the health of those who will be in the gazebo.

Device

The ideal option for a stove device is the initial design of a gazebo along with a barbecue. Sometimes the capital stove is placed separately from the building, but more often it is located inside the gazebo. The location of the structure must be safe and convenient. The stove must not interfere with free movement.

The location of the stove should be chosen from the leeward side in relation to the residential building. You cannot equip a capital stove on the street near a residential building. In addition, it should not be installed near growing trees. The cooking area can be finished with porcelain stoneware or tiles for added safety.

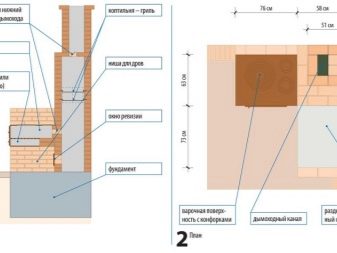

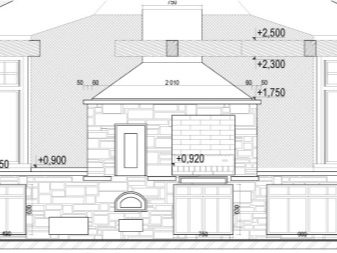

Any business requires an initial project. In its development, it is necessary to take into account the weight, dimensions, and appearance of the structure. In construction work, it is important to strictly follow the created project, reflecting all the nuances of construction in the drawings.

At the same time, each step of creating a furnace must be performed thoroughly and accurately.Compliance with the technology will allow you to get a high-quality product that will serve for many years, delighting the owners of the house with good work.

Varieties

Examples of stoves for gazebos suggest the creation of a variety of options.

This could be:

- Russian stove;

- heater;

- fireplace;

- B-B-Q;

- complexes with various modules.

Russian ovens are traditional for Russia, but barbecues and barbecues are more common today. A real Russian stove in the gazebo is unlikely to fit, since it is massive in size. To save free space, a more rational version of a mini Russian stove is usually used. The device is rather a brazier, which is simply made in the Russian style.

Such a device, equipped with a stove, is convenient to use not only on the street: it is also suitable for the kitchen of a private house. The grill and stove allow you to prepare a wide variety of food options (except for baked goods). A classic stationary brazier is a godsend for small areas. Despite its small size, the device allows you to cook several dishes at the same time on the grill and skewers.

Kitchen modular complexes usually include a spit, grill, smokehouse, stove, on which a cauldron can be installed. The device is suitable for several tasks. But the complex requires a powerful monolithic foundation, which can be attributed to the disadvantages of the structure. Its construction is a rather troublesome undertaking. A fireplace, which is installed in homes for aesthetic purposes and heating, can be built in a gazebo.

An outdoor fireplace stove is a useless cooking device. Rather, it is needed to enhance aesthetic functions.

How to choose?

The choice of material for building a furnace today is quite wide. In the modern construction materials market, the leading brands offer a wide range of products.

Several types of bricks can be used.

- Heat resistant. This brick has a red tint and has no holes.

- Ceramic (clay). Retains high temperatures, accumulates heat efficiently. Visually, this type of clay bricks is difficult to distinguish from other options that do not have heat-resistant characteristics.

- Fireclay brick. It has refractory properties, but it is more often used as cladding or for decorative inserts.

In construction projects, the use of materials is usually assumed in an integrated manner. But you can use one type of material for the entire structure. Its functionality depends on the choice of materials for building a street stove.

For example, if the complex is protected during construction with a layer of thermal insulation, then the hearth can be used all year round. The design will be able to work not only for cooking, but also for heating.

A brazier-type device can be built in the form of an oven. The mode of operation of the device will remain similar to the barbecue. At the first stage of use, the device is well heated. Then you can put meat on skewers in the firebox. Due to the uniform heating, the kebabs will not need to be constantly twisted, and there will also be no need to monitor the cooking process. The leader in the choice of design is the barbecue, it is built on the prototype of mobile braziers. The stove is distinguished from the barbecue grills by a stationary grill, on which you can cook meat.

Multifunctional designs involve the placement of skewers. This stove is of particular interest to many owners of private houses.

The stationary design assumes mandatory protection of the flame from precipitation and wind. The covered device contributes to the long-term preservation of the heat. Outdoor barbecues are made of metal. The body of a stationary stove can be made of bricks with high refractory characteristics.Stationary complexes are often placed in gazebos, which include stove equipment, sewer systems, a sink, furniture, tables (everything that can be useful for cooking on the street).

Construction

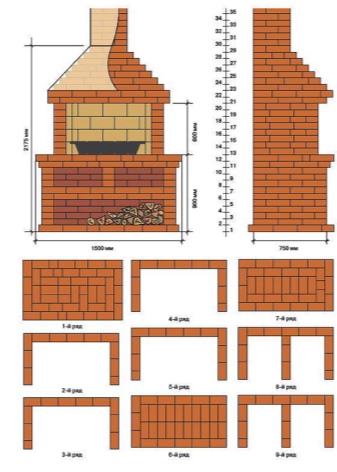

The dimensions of the stationary stove are small, so the amount of material for manufacturing will require little.

You can use the standard scheme:

- ordinary brick - 360 pieces;

- fireclay bricks - 120 pieces;

In addition, you will need a solution of clay and sand. At the same time, it is important to know a nuance: the mortar intended for brickwork must necessarily be of such a consistency that it will exclude its sticking to the tool, but at the same time will not allow spreading over the surface of the brickwork. The stages of construction are directly related to the type of construction selected.

The main point in the work is the construction of the foundation. Let's take a closer look at this process.

Foundation

With the simultaneous construction of a stove and a gazebo, the base under these two structures can be the same. When installing the stove in a finished gazebo, you need to choose the right place. The principles of arrangement are usually common with the arrangement of a fireplace. For example, draft-free and safety is important.

A pit is dug under the base, the depth of which should be 50-60 cm. Gravel is laid at the bottom of the pit and tamped. The next stage is reinforcement, you need to make a wire mesh, and install formwork around the edges. Next, fill the hole with concrete to a level below 5 cm from the floor.

Leave to cure, depending on weather conditions, for about 20-25 days. To prevent the appearance of chips, it is recommended to wet the hardened concrete with water. After the curing period has expired, install a waterproofing material (for example, roofing material). The next mandatory step is the construction of the stand.

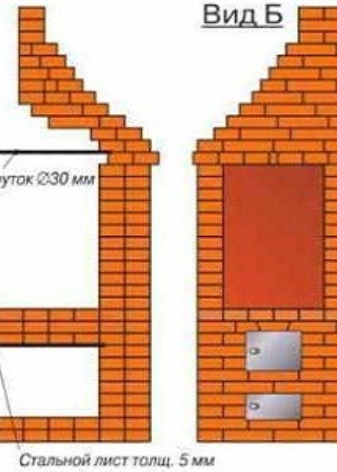

Erection

The stand is stacked taking into account the ordering drawing. Hollow brick is suitable as a material. If the work is done by hand, the dressing should be taken into account, specifying the evenness of the rows and corners with a level. Pay special attention to the first six rows of the order. They will be the place for shelves under the countertop. 7th row - overlap of the hearth, 8th row - dressing of the overlap and the beginning of the bottom of the furnace.

Firebox

Performing the 9th row, you can use chamotte. When lining, the main attention should be paid to the thickness of the mortar: it should not be more than 3 mm. To ensure the thermal expansion of this type of brick, the transition between the two types must be at least 20 mm. If there is no transition, chamotte will crack during use, and the firebox will deform.

The temperature range is laid out with a basalt cord. It is non-combustible and has thermal insulation properties. The 10th row is a continuation of the furnace with a simultaneous narrowing. 11th row - completion of the firebox laying. Here you can already install the grate (grates).

Working surface

It is possible to use stone or tiles here. Both materials have the desired properties.

Brazier

The brazier is formed starting from the 12th row (from a ledge of one brick for a skewer). The brazier space should be laid out from rows 13 to 16. The formation of the walls ends on the 17th row.

Vault

If the experience in arranging stoves is not great, then it is better to form the vault according to a template prepared from cardboard. The template must be drawn on bricks, marking the points with a marker. The brick is subsequently cut off according to the marked marks, forming a vault. For better stability, the mandrel can be made of solid wood. You can remove it after the solution has completely dried.

Next, a chimney is erected. Consider the insulation of the structure at the point of contact with the roof of the gazebo. Insulate the floor near the stove, insulate the walls and ceiling. The stage of installing the hood and chimney can be simplified, since the components can be purchased ready-made. Instead of bricks, sheet metal can be used at this stage.

As soon as the masonry is formed, you can arrange a cutting table.The countertop should be sized to match the size of the brickwork. Wood, stone slab, plywood and cast iron can be used as materials for the countertop. The latter option can act as a built-in hob on which you can cook food.

The table top can be equipped with a sink. This is convenient, but requires the installation of water pipes. A special waterproof silicone sealant must be present between the bricks and the edge of the countertop. For an aesthetic design of the space, a niche under the table top, you can arrange doors. The material for them can be very different.

Nuances of use

If the stove is made in compliance with the technology, it will serve for a long time. When choosing a place for construction, you must immediately be guided by the main principles, which include the direction of the wind rose and the presence of a high-quality territory. Most often, the stove is used so that fumes and sparks do not fall towards the house and other utility structures. In order for a massive structure to look harmonious in the gazebo, it is important to choose the right cladding.

It is assumed that the section of the foundation in front of the gable part of the furnace should be made of a material that is resistant to fire, preferably with a rough surface. For example, porcelain stoneware tiles are ideal. The brick structure itself can remain without finishing. The stove can be plastered or covered with ceramic tiles.

The appearance of the stove will depend on the chosen finishing option, but at this stage it all depends on the decisions of the owner of the structure.

Let's consider other nuances.

- The main nuances of using a stove in a gazebo are incorrect operation of the chimney and improper operation. For example, your brick oven will quickly deteriorate if you fill fuel with water. This method will lead to the destruction of the building in several sessions of use.

- Pipe problems are often caused by gusts of wind. Therefore, it is important to arrange the structure so that there is no reverse thrust. Otherwise, the gazebo will be filled with carbon monoxide.

- Another problem with the pipes of street stoves is the ingress of precipitation. Therefore, gazebos with a stationary stove are often equipped with a brick or metal frame. The roof of the structures is covered with corrugated sheet or tiles.

- The ideal location of the stove in the gazebo is in the end part with a turn with the back side out. This way, the combustion products from the stove will not get inside. A wide stone wall of the oven box will keep you warm.

The use of stationary stoves in gazebos is most common in cafeterias and street restaurants. For a private estate or summer cottage, it is more convenient and practical to use mobile devices that are easy to maintain. The devices can be installed in any gazebo without fear of fire or smoke. Ready-made stoves for gazebos are produced in various solutions.

Modular assemblies are very popular. The performance characteristics of such devices correspond to the parameters of a good homemade brick oven. The main disadvantage of purchased options is their high cost. You can reduce spending if you buy modules gradually. One or another unit of a complex device can always be purchased separately.

In this video, you will find step-by-step instructions on how to build a gazebo with a brick oven.

The comment was sent successfully.