How to repair a gasoline generator?

Today it is difficult to imagine our life without electricity. It is precisely this that is the "fuel" for technology and makes any human activity simpler and easier. And very often in places where there is no electricity for some reason, we understand how important it is.

Recently, a device such as a gasoline generator has been used to generate electricity. But he, like any other technique, can break. Let's try to figure out the problems of gasoline generators and how to repair them with our own hands.

Common malfunctions

If we talk about the most common malfunctions of electric generators of any type, then the following problems can be named:

- contamination or failure of spark plugs, which is expressed in the unstable operation of the generator, its difficult start;

- clogged carburetor: too high fuel consumption, instability in the presence of a permanent load, difficulties with starting the device;

- breakdown in the ignition coil: it is impossible to start the gasoline generator, there is no spark;

- starter problems: biting and breaking the cable or destruction of the ratchet mechanism;

- violation of valve clearances - in this case, there is too much noise during operation and difficult starting of the gas generator;

- wear of brushes on synchronous models, it becomes the reason that the device does not produce an output type current;

- broken regulator speed becomes the reason for their swimming and failures in work when changing the load;

- wear of the generator rotor and crankshaft bearings cause oil leakage and increased operating noise;

- wear of the cylinder and piston rings becomes the cause of excessive consumption of oil and difficult starting of the engine if it is cold.

You should also take into account quite common malfunctions, the cause of which will be a violation of the rules for using the device. These include:

- burnout of generator windings or voltage transformer during permanent overloads;

- crankshaft seizure due to low oil level.

Gas generator malfunctions can be divided into 3 categories:

- malfunctions of ignition and fuel mechanism;

- mechanical;

- electrical.

Ways to eliminate breakdowns

Now let's talk about how to repair the device in question with your own hand when the most common problems occur.

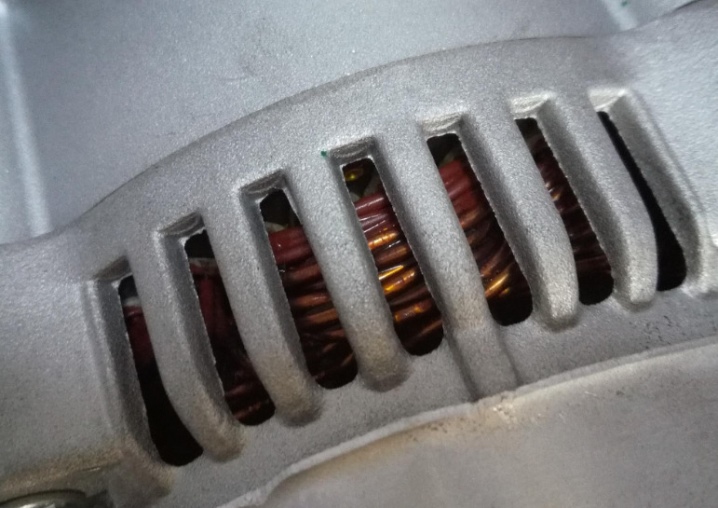

Dirty air cooling fins

One of the fairly common problems that can appear when working with a gasoline generator is dirty air cooling fins. The reason for this can be two things. In the first case, we are talking about the fact that the device was not used for a long time, dust settled on it, which got inside. It is natural that during the active operation of the device, the system will overheat, which sooner or later will simply burn out.

The solution to this problem can be found in any manual for any model of gasoline generator.

It can also appear for another reason - the use of low-quality fuel can cause carbon deposits to appear on various filters and on the cooling mechanism of the device as well.It can be eliminated very simply - the air cooling fins should be very thoroughly wiped with a cloth from dust and dirt. If you wish, you can do this without disassembling the device, but it will still be better to disassemble it, you need to remove the part and carry out its high-quality cleaning, and then install it in its original place.

Ignition system problems

If there is a problem with the ignition mechanism, which is expressed in an increase in engine noise during operation or in a difficult starting of the generator, then this problem must be looked for either in the operation of the carburetor or in the ignition mechanism. Despite the interconnectedness of the two systems, solving problems with them should be considered separately. In this case, you will first need to unscrew the spark plug and inspect its condition.

More precisely, you should look at the carbon deposits that should form on its electrodes.

- If it is extremely dense and dry and black in color, this indicates that a rich mixture is being used. This means that it is either a carburetor or a clogged air filter.

- If the deposit is black but oily, then this means that the piston rings are very worn out, and the oil ends up in the combustion chamber, where it should not be.

- If the carbon is white, this means that the mixture is extremely poor, and most likely the carburetor is faulty.

- Brown carbon deposits with a brick shade indicates that everything is in order with the engine, and carbon deposits, which are red or green-red, indicate the use of low-quality fuel.

In general, the serviceability of the ignition mechanism is easy to check, because its structure is very simple. To do this, you need to activate the ignition, put a working candle in the corresponding cap, then, putting it with a skirt on the nearest part of the engine, made of metal, make a sharp crank of the recoil starter.

- If there is no spark, then first disconnect the lock from the ignition coil, and then the sensor that shows the oil level.

- If, after turning them off, a spark does not appear, the coil should be replaced.

- If there is a spark of normal strength, then after a couple of starting attempts, remove the spark plug.

- If it is filled with fuel, then the mixture is too rich.

- If it is dry, then it is missing.

It also happens that after long-term storage, the carburetor float and the needle stick, because of which gasoline does not enter the system. To fix this, you should not hit too hard on the float chamber lid a couple of times and make another start.

No voltage

Note that the electrical mechanism of the considered devices is considered to be quite reliable. Usually there can be only two problems with it - or there is no battery charging on devices where there is an electric start, or there is no voltage at the generator output at all.

- The first malfunction is the result of a breakdown of the low voltage winding or rectifier. It is very easy to check the entire mechanism yourself. It will be enough just to connect a 12 volt light bulb in parallel with the low voltage generator winding and start. If the light is on, it means that the generator is working properly and the rectifier needs to be replaced.

- If there is no voltage at the generator output, then most often this is the result of wear on the brushes. They should be pulled out and checked for wear. If it is large, it would be better to replace them. If you have an inverter-type generator, then you should check whether the voltage goes to the converter input by connecting a low power 220 V lamp in parallel.

Fuel system malfunctions

Fuel system problems can usually be caused by 2 reasons. The first is the use of low-quality fuel, and the second is the ingress of water or air into the fuel line, or creating a blockage caused by the use of low-quality fuel. In addition, there may be problems with the carburetor.

If dirt gets into the fuel jets, the fuel mixture becomes leaner and fuel starts to leak.

To fix this problem, you need to figure out how to service the carburetor.

- First you need to remove the camera cover with the float. It needs to be washed in gasoline or with a special aerosol-type carburetor cleaner. This is necessary to remove dirt and various types of deposits that often accumulate at the bottom. The same goes for the gas crane sump.

- Now you should check whether the valve is purged when it is in the "open" position.

- Now you need to pull out the axis of the float, remove it completely together with the lock-type needle. Air should be blown through the channel.

- Now use compressed air or an aerosol cleaner to blow through the emulsion tube, fuel jet as well as all carburetor passages. We unscrew the adjustment screw, and then blow through its channel.

- After that, we wrap it all the way and loosen it, depending on the type of air filter, by 2 or 2.5 turns. It remains to assemble the carburetor and check its performance.

Launch problems

If we talk about problems with starting, then they are usually caused by a breakdown of the starter. The simplest solution would be to repair the manual starter of the gas generator. Then the problem may lie in the not very high-quality fastening of the return-type spring.

But in most cases, the starter has to be repaired due to improper use of the device, when the user makes too much effort to start.

If, after examining the mechanism, it became clear that this is not the cause of the malfunction, then it will consist in the breakdown of one of its elements. This can be either a break in the cable, or the refusal of the starter to rewind it due to the fact that the return spring is broken. Another option - the ratchet does not rotate the crankshaft.

Remove the starter by unscrewing the bolts around the perimeter of the casing. The ratchet can then be removed. We check its return springs and cams. Then carefully pull out the pulley and spring. We are replacing a cable that broke off, or a broken spring.

When assembling the starter, make sure that the spring is in the hitch with the casing and the pulley during assembly.

The cable must be completely wound around the pulley.

Preventive measures

Clean the device from time to time. We are talking about cleaning the fuel tank, as well as the elements of the cooling system from carbon deposits and dust. This will keep the device clean, and blockages will not cause overheating and subsequent failure.

In addition, it will not be superfluous to disassemble it from time to time and check the performance of various mechanisms.

Especially carefully it will be necessary to check the ATS and the operability of the control unit. If possible, it will not be superfluous to also clean the internal elements of dirt and dust. Given the design features of this device, there are no large-scale preventive measures for it.

To this you can also add fuel and oil level monitoring, checking the strength of fastening of various elements with bolts, as well as periodic cleaning of the air filter from dirt and dust.

Recommendations

Users who have the necessary theoretical and practical knowledge can use the instructions for repairing a gasoline generator. Usually in such materials you can find information on how to fix the most common problems with certain devices. That is, a person himself will be able to repair a gasoline generator, which will save him money.

And the main advice of specialists will, of course, be that any breakdowns should be prevented.

This is possible if you service such equipment in time, checking the level of oil and fuel in it, as well as checking the strength of bolted connections and cleaning the air filter from dirt. As a result, repairs may not be required at all during the use of the gas generator.

In general, it should be said that repairing a gasoline generator with your own hands requires certain knowledge, which is why not every user will be able to carry it out... In this case, it would be better to consult a specialist. But if you have a theoretical base, then you can repair the basic malfunctions of a gasoline generator without much difficulty.

In the next video, you will learn what, first of all, must be done if the gasoline generator is not working.

The comment was sent successfully.