Everything you need to know about basalt slabs

More than tough competition has developed in the modern market of building and finishing materials. And this is also true for the segment of foamed sheet polymers. Given the fact that basalt slabs have every chance of being the leader in their class, many are now interested in everything there is to know about the properties, performance and scope of the panels. It should be noted that this popularity is primarily due to the unique characteristics of mineral fiber insulation.

What it is?

Initially, it should be noted that the type of insulation under consideration is as close as possible to mineral wool in its properties. This largely determines its prevalence in Russia. To understand what exactly basalt slabs are, it is worth paying attention to their main advantages and disadvantages. The list of clear and most significant advantages includes several characteristics.

- Reduced coefficient of thermal conductivity due to the fibrous structure. Thus, a 10 cm slab in the context of thermal efficiency is comparable to heat insulators, the thickness of which is up to 30 cm.

- High noise absorption, which, along with the previous property, contributes to the creation of the most comfortable microclimate inside the room, the walls and other structural elements of which are finished with the considered insulation.

- Increased resistance to aggressive chemical environment. We are talking, in particular, about acids, alkalis and technical oils. Due to this characteristic, the plates are widely used in the insulation of blast furnaces, various types of technological equipment and pipelines.

- Refractoriness, allowing the material to be used in almost any operating conditions.

- Strength and long service life, which determine the ability of the insulation to maintain its shape for the longest possible period.

- High rates in terms of vapor permeability, which directly depend on the observance of the installation technology of the sheet heat insulator. With proper installation, excess moisture is transported outside the premises with the utmost efficiency.

- Resistance to the effects of a biologically active environment. For example, we can talk about causing harm by insects and / or rodents.

- The most simplified process of mounting plates. The entire range of work can be performed almost alone, which in itself significantly reduces financial costs.

Naturally, there are certain disadvantages. First of all, we are talking about the need for strict adherence to the rules provided by the technology. The durability of the insulation and its performance directly depend on this.

Often, over time, gaps can form between individual panels of insulation. As a result, the sound and, most importantly, the thermal insulation of the room deteriorates significantly.

How are slabs made?

The described variety is made from several rocks. The list of raw materials includes basalt, diabase, dolomite, and limestone. They are processed at elevated pressure using special equipment. The result of the corresponding processes is thin, but at the same time the most durable fibers that form the basis of future insulation boards. The technological process in this case is as follows:

- raw materials obtained from volcanic rocks are crushed in crushers and heated to 1.5 thousand degrees;

- a "melt" is obtained, consisting of fibers with a diameter of up to 88 microns and a length of 1 cm;

- an inorganic component is introduced, which provides a strong bond between the fibers and the insulation itself;

- produce high-temperature vacuum pressing of plates having a certain density;

- the resulting material is dried in special ovens at elevated temperatures.

Today, companies specializing in the production of basalt slabs offer 4 types of products on the market. Taking into account the operating conditions, as well as the weight characteristics, the following categories of panels can be distinguished:

- light - density is from 15 to 20 kg / m3;

- medium - from 35 to 40 kg / m3;

- slabs with a density ranging from 50 to 70 kg / m3;

- heavy - from 150 to 170 kg / m3

It is important to take into account that, regardless of the parameters given, the key properties of the fiber remain unchanged. In other words, only the packing density of the matrix is varied during the production of the slabs.

Basic properties

Today, due to the minimum weight and maximum strength, basalt slabs deservedly occupy a special place in their class. In terms of a number of characteristics, they have no competitors among modern heat and sound insulators. According to current statistics, they account for about 70% of the market. That is why it is worth paying attention to the main parameters of this insulation, which has found wide application in construction and other areas.

Heat insulation and sound insulation

As already noted, the structure of the material under consideration is formed by the finest fibers, which are randomly intertwined. As a result, very small cells are formed. It is important to take into account that they contain air, due to which unique thermal insulation properties are provided. At the same time, the material has a minimum thermal conductivity, which fluctuates in the range of 0.032-0.048 W / mK. In other words, a basalt slab with a thickness of no more than 100 mm is capable of providing thermal insulation, in terms of parameters comparable to that of a wall made of silicate brick 140 cm thick.

Along with the aforementioned characteristic, the described structural features also determine the soundproofing component of the mineral wool slab. So, insulation with a thickness of 30 to 50 mm is capable of absorbing up to 500 Hz and even higher. For 125 and 250 Hz, the absorption coefficient is 0.2 and 0.65, respectively. The same indicator, with an increase in the thickness of the slabs to 10 cm, rises to the marks of 0.45 and 0.9.

Water vapor permeability, hydrophobic properties

Fibers of basalt insulation boards are water-repellent. Due to the presence of various additives, manufacturers are able to significantly improve these hydrophobic characteristics. The point is that the material does not retain steam and moisture, that is, the main characteristics in this case are the minimum water absorption (within 1.5%) and increased vapor permeability.

As a result, we can talk about almost instantaneous removal of all excess moisture into the atmosphere. This avoids the risk of condensation, fungi, mold and rot. In practice, the material remains as dry as possible even in conditions of high humidity outside the room.

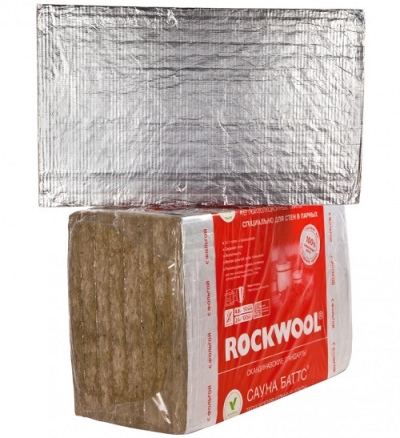

Such properties make it possible to effectively use the stove when decorating saunas and baths.

Non-flammability, fire safety

If the basalt slab fully meets the standards of GOST, then it is characterized by:

- increased resistance to high temperatures;

- minimum smoke production rate;

- lack of toxicity of combustion products;

- incombustibility (is fireproof) and fire safety.

By the way, at a temperature of 1 thousand degrees, the melting of the material begins only after 2 hours.It is worth considering that samples of insulation that do not meet current standards may be on sale.

Other

In addition to all of the above, it is necessary to pay attention to a whole list of important characteristics of the described heat insulator. And in this case, we are talking about the following competitive advantages that provide him leadership in the relevant segment:

- ecological cleanliness and safety;

- increased strength (plates do not deform under the influence of various factors and retain their shape throughout the entire service life);

- resistance to the negative effects of vibration and deformation;

- ease of installation.

Attention should be focused on the fact that basalt slabs do not contain substances that can harm the environment and human health.

Species overview

Taking into account the purpose and performance characteristics, several categories of the considered thermal insulation material can be distinguished.

- Soft boards designed for minimal loads and having a porous structure, which makes them the most effective heat insulator.

- Sheets of medium strength, most often used for arranging ventilated facades, finishing air ducts with protection against the penetration of an open flame in a fire, as well as for creating sound insulation.

- Rigid slabs that are able to withstand significant loads without any damage to thermal insulation performance. This variety is widely used when performing outdoor work, as well as for insulating floors and frame partitions.

- Foil basalt insulation. In this case, the main feature is the ability to partially reflect heat. It should be noted that the foil can be present on one or both sides.

Dimensions (edit)

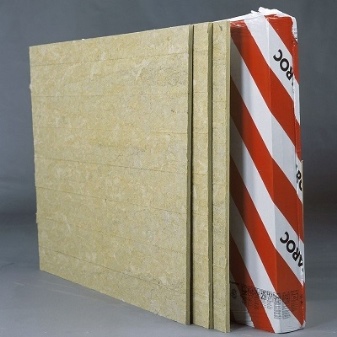

Today, the most common parameters of the described insulation boards are 1200x600 mm. On sale now you can find panels, the thickness of which varies in the range of 20-120 mm (1200x600x20, 1200x600x50 mm and so on). In addition to the dimensions of the slab, its weight should also be taken into account, that is, there are two key factors that affect the ease of installation. With a weight of several kilograms, it can be laid even in the most inaccessible places without assistance and excessive effort.

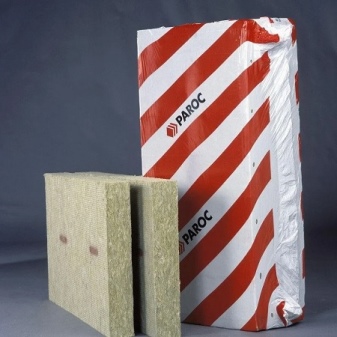

Popular manufacturers

Given the record popularity of the insulator in question and the outstanding performance indicators, many well-known companies are engaged in its production today. Several brands occupy the leading positions in the current ratings.

- Knauf - a German company, which is rightfully considered one of the world leaders, including in the production of basalt slabs. It began its history back in 1932, that is, it will soon celebrate its 100th anniversary.

- Rockwool - a manufacturer of modern heat insulators based on basalt and stone wool. One of the clear competitive advantages of the company is a wide range of products and standard sizes. Their distinctive parameters are also strength and density.

- Izovol - a leading domestic brand in the development and production of thermal insulation panels, including basalt slabs. Due to the wide range of products presented on the Russian market, a potential consumer has the opportunity to choose the most suitable material in each specific case. And also the list of competitive advantages includes an affordable cost with an optimal ratio of price and quality of products.

- Isoroc - a large company specializing in the manufacture of a wide range of thermal insulation materials that meet current standards. In the segment of basalt panels, it offers buyers a fairly large selection.

- Technonikol - the manufacturer of the described materials, which are deservedly popular in the Russian and other markets.The products are characterized by high quality, durability and increased strength.

When choosing a particular brand of basalt-based insulation, it is strongly recommended to pay special attention to the quality of the material. It is from him that such performance indicators as the durability and the level of heat and sound insulation directly depend.

Areas of use

Being an environmentally friendly material, mineral wool board is currently widely used in modern multi-storey and cottage construction. It is worth noting that the panels are equally effective in finishing both erected and already finished buildings and structures as part of their renovation. Taking into account its refractoriness, the material is successfully used for insulating areas around the stove in baths. In practice, basalt slabs are most often used for finishing various objects and structural elements. Let's list the main ones.

- Enclosing structures of any configuration.

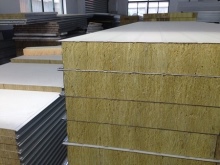

- Medium cavities in multi-layer walls (brick, gas and expanded clay concrete), as well as in sandwich panels.

- Facades on which the material is laid on glue, followed by plastering or applying any other protective layer. Among other things, plates are used when it is required to insulate a log house.

- Wet and ventilated facades.

- The bottom and top layers in multi-layer and flat roofs, respectively.

- Hulls, partitions and machine assemblies in shipbuilding.

- Chimneys, heating boilers and other boiler equipment.

It can be concluded that with the help of basalt slabs practically any structural elements of structures - from foundations to roofs - are successfully insulated. And also these panels have found application in various areas of industrial production and energy.

Do not forget about such quality as incombustibility, which expands the scope of use of the plates.

The comment was sent successfully.