Plastic pools: types and do-it-yourself manufacturing

Plastic pools are becoming more and more popular. There are many types of such containers. However, making a plastic pool with your own hands for skilled people is not difficult.

Advantages and disadvantages

The persistent popularity of the plastic pool is due to its outstanding performance. Plastic is durable. It is mechanically strong and therefore can effectively resist destruction. Such material is environmentally friendly (of course, if it is professionally made). Good plastic perfectly tolerates contact with aggressive media, in addition, it is frost-resistant and heat-resistant material.

The plastic bowl always looks very good. The technology for obtaining beautiful pool structures has now been worked out at a decent level. In this case, the bowl will be completely sealed and reliable during operation. Since plastic does not conduct heat well, water will retain it longer. This material also does not contribute to the formation of colonies of pathogenic organisms.

The plastic tank can be mounted quickly enough. It itself is relatively lightweight, which simplifies both installation and transportation. The shapes of the plastic bowl are very different. However, it is impossible to deliver such a product in a finished room. It is necessary to provide for its installation during construction.

Species overview

By territorial location

Ready-made outdoor pools for summer cottages and for houses outside the city always have an open design. The best option for an outdoor bathing area is hard to wish for. Installation of such a structure is possible at any arbitrary depth. The garden pool is a type that deserves special attention. It should be placed on level ground, where no shadow falls from trees and other objects, including the walls of houses.

Additionally, when characterizing the location of the bathing place, take into account:

- its remoteness from the house and from other buildings;

- protection from prevailing winds;

- ease of use of the water supply.

It is very important to protect from the wind an artificial reservoir for a bath. A similar cover can be provided with the help of a fence erected around. But the fence is not very convenient in a small area, where you have to save every square decimeter. Children's containers are best placed under the cover of the walls of the house. True, it will provide protection from only one side, but the approaches will be completely free.

They often try to place the pool closer to green plants, especially trees. This is an inexpensive option, but not practical. Foliage and small twigs will constantly pour into the water and clog it. However, if other options do not suit you, the "green barrier" will do. But it is necessary to put the pool at a distance of at least 2 m from the bowl itself.

By the depth of immersion

The deep pool dug into the ground allows you to enjoy swimming in the hot season and keep yourself in good shape at other times of the year. Although the installation of such a container is not too difficult, it will require a solid foundation pit. At the same time, sewer and drainage circuits will have to be added to the depth of the bowl itself. Drop-in pools can be easily assembled. It is also easy to disassemble them as soon as the need has disappeared.

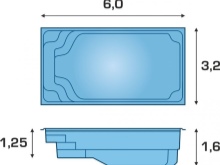

The above ground pool also has its pros and cons. Such a structure cannot, by definition, have a depth of more than 1 m. But for many people this is not necessary. For children no older than 5 years old, you need to limit yourself to a bowl with a depth of 0.5 m. But swimming pools for schoolchildren and most adolescents should not be smaller than 1.44 m. For adults, this value will no longer be enough.

When planning to make jumps, you need to make out a bowl with a depth of at least 2.3 m. This is mandatory even when the height of the tower does not exceed 1 m. Otherwise, there is a high risk of a strong impact on the bottom. If a tower of 3-4 m is used, you need to focus on the bar from 3.15 m. All these dimensions can be safely increased by 10-15%, and then using the pool will be quite comfortable.

By type of bowl

The next important point to consider is the type of bowl. Prefabricated (they are collapsible or frame) structures are quite rigid. Modern varieties of plastic make it possible to ensure the operation of the bowl not only in the warm season, but also at any time of the year. However, the greatest strength and stability are stationary pools, which cannot be moved to another place. Dismountable design is often provided by means of racks mounted vertically and horizontally.

Each such rack has a special mount. The delivery set usually includes a polymer cover and a pump with a special filter. Such core basins are quite convenient, but they can be easily damaged and punctured.

Even the best collapsible structures are still advised to dismantle and put away in a safe place for the winter. Sectional models are now quite widespread.

Segments can be connected with glue, locks or bolted. The depth of the sectional structure varies from 1.2 to 2.4 m. Rigid frame models are equipped, in comparison with sectional ones, with additional supports. Guide profiles and transverse beams are also used.

Important: from time to time in collapsible pools it will be necessary to update the liners.

Materials (edit)

For the manufacture of a polymer pool, sheets of quite different materials can be used. Blocks of industrial polystyrene foam are often used. The installation procedure and basic properties are the same as for bricks. However, compared to ordinary bricks, thermal insulation is much better here. Accordingly, the water will cool down at times slower.

Expanded polystyrene has excellent rigidity. It will last a very long time. A wide range of accessories can be used on a Styrofoam pool. You can also choose the shape and size of the bowl at your discretion. But it must be remembered that:

- polystyrene foam structures are relatively expensive;

- it is not too easy to mount them;

- for work, you will need to drive special equipment to the site.

A plastic bowl is the lightest and easiest option... It can be applied almost anywhere and does not require complex techniques. The monolithic bowl perfectly survives the effects of aggressive substances and harmful ultraviolet radiation. It is not difficult to mount it.

However, customization can be quite expensive, and sometimes you have to give up additional accessories.

Another option is bowl made of polypropylene sheet. This material is impervious to both water and various gases. In addition, polypropylene bends easily, and this property is also appreciated. Another of its properties is worth noting:

- impact strength;

- chemical inertness;

- excellent reliability.

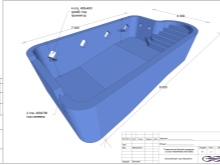

Shapes and sizes

These parameters must also be taken into account. The size of the structure directly depends on whether it will be comfortable and practical. But building very large pools is expensive, difficult and difficult. Ideally, the dimensions and geometric configuration of the bowl should be chosen during the design of houses and plots. Then it will be possible to ensure perfect performance and equip all communications.

The situation is much more complicated in the already used areas. Then it is necessary to fit the bathing area into the gaps between the created structures. Sometimes you have to use a mini-pool, since the layout of the territory does not leave any other option. When a bath is equipped inside the house, baths (saunas), one must be guided by the size of the building itself. If there are no such restrictions, the first thing to consider is the number of users; 1 bather must have at least 2 cubic meters. m of water.

Traditionally, in dachas and in country houses, rectangular, square pools are used. In clay soil, the rectangular type of bowl is more stable than the round version. Any shape can be used in sand and rocky mass.

However, one must understand that the more complex the geometry, the harder the installation of the finished structure will be. For those who do all the work with their own hands, this circumstance often becomes a decisive argument in favor of simple forms.

How to choose?

If the polypropylene bowls are not too satisfactory, you can pay attention to the fiberglass structures. This is a more versatile material that is appropriate for a wide variety of landscapes on the site. However, it will be invariably more expensive. Therefore, the vast majority of people still prefer polypropylene. The next important point is whether to make a custom-made pool or limit yourself to standard models (which are cheaper, but less diverse).

For a family with children, you need to choose structures that are heterogeneous in depth. You also need to consider the following points:

- personal tastes;

- compatibility with the landscape;

- ease of cleaning;

- general ease of maintenance.

Installation rules

Competent installation of a plastic pool, as already mentioned, implies removal from large trees and dense bushes. It is also very important to place the bowl where there are no other sources of debris. The pit should be 1 m wider than the bowl and 0.5 m deeper than the top edge. Only then will it be possible to lay all communications and create a concrete support. Recommendation: on an area with difficult, unstable or heterogeneous soils, it is better to contact a professional.

The concrete base and walls of the same concrete cannot be thinner than 0.3 m. Otherwise, they will not be reliable enough. Be sure to reinforce the support with a metal bar. The standard lattice spacing is 0.2 m.

Important: the rods must go both longitudinally and across.

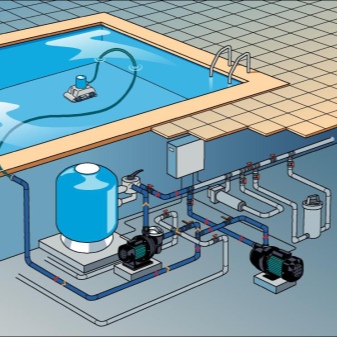

It is necessary to connect parts of the reinforcement using a metal wire. Winding one joint will require approximately 0.4 m of wire. Apart from the involvement of an excavator, you will need to use:

- shovels with a shovel and bayonet;

- a mallet with a rubber working part;

- cords;

- stakes;

- concrete mixers;

- extruders (allowing to work with polypropylene);

- carpentry knives;

- stairs;

- buckets;

- building levels.

The dug earth is left and used to fill the voids. After digging a pit, beacons are placed that will show the upper edge of the structure. The base of the pit is properly leveled and tamped. Then crushed stone is poured, achieving a layer 0.3 m thick. The base is leveled exactly at the level.

Next, a reinforcing lattice is mounted, resting on the brick halves (to avoid touching the crushed stone layer). The diameter of the rods in the lattice is exactly 1 cm. The next step is pouring concrete. To ensure the flow of mortar from the concrete mixer, it is worth making a wooden gutter. The slab should be made 0.5 m wider than the pool itself.

Under normal conditions, the concrete base will be ready for use in 5 days. At an air temperature of less than 5 degrees, it will take at least 20 days. But such a situation does not at all dispose to the beginning of work. On hot days, it is recommended to cover the concrete fill with polyethylene. The dried base is covered with thermal insulation (most often with foam, a little less often with hydro-textiles).

Attaching the bowl begins with filling the gap that separates the sides from the ground. A layer of concrete 0.4-0.5 m is poured there. The gap is filled in layers, waiting first for the lower layer to completely solidify. You will have to wait 48 hours. At the same time, the pool is filled with water to the level of the poured concrete.

Important: it should be monitored so that the structure is not subjected to deflections. Water helps to avoid such deformation, but you still have to observe. As soon as the concrete reaches the upper edge, all residual voids are covered with soil and rammed.

How to do it yourself?

The manufacture of a polypropylene pool will require the use of sheets of unequal thickness. The walls are usually made thicker than the bottom. You can use standard sheets with a thickness of 0.5-1.5 cm. But it is better not to take material thinner than 0.8 cm. It is easily deformed, even when concreting and hardening of the concrete mixture.

According to builders, the wider the created bowl, the thicker the plastic should be. Construction begins step by step with the preparation of the building site. You need to prepare even where something has already been built, and if nothing has been built on the site yet, even more so. Even before assembling the plastic frame, you need to:

- dig a pit;

- lay pipes;

- connect electrical equipment;

- decorating and landscaping the surrounding area.

The simplicity of the forms, by the way, will further facilitate the calculations of the required amount of materials. In any case, the formation of the bowl begins only after the concrete base has solidified. Hot air is fed from the extruder to the polypropylene, and a polypropylene rod is introduced into the softened material. It also begins to melt, and as a result provides a joint between the sheets. Cutting blocks from sheets should be done exactly according to the pattern.

Having cut the outlined parts, they are soldered from the outside. For this purpose, nozzles are used designed for unfolded corners. Important: the edges of the polypropylene sheets should be cleaned, otherwise a 45-degree double-sided bevel will not work. Then they put the central part of the future bottom. Side sheets are placed at the edges, welding rods are used at the inner joints, and the outer ones are connected with extruder nozzles.

The work on the steps of the pool will take place in the same way. Having welded all the details, they are taken for stiffening ribs. These are strips of polypropylene running vertically at right angles to the bowl. They are welded according to the already described technique. A gap of 0.5-0.7 m is left between the ribs.

Next, the resulting bowl is attached. Pumps and filters can only be installed in a fixed structure. Suitable holes are drilled in the housing and pipes are laid in them. The lighting system is mounted as needed. We must not forget about the necks for plumbing communications.

PVC film or butyl rubber film will help to provide the required texture and color of the bowl. Their sheets are laid on the bottom and applied to the walls of the pool. The edges are wound with an overlap. You need to fix the coating with cold welding glue. Planks or paving slabs are placed around the pool, wooden coatings are impregnated with antifungal mixtures.

How to install a plastic pool, see below.

The comment was sent successfully.