Pool pumps: types, selection rules and repair tips

The pool pump is an integral element of the "life support" system, a means of maintaining order, it is not surprising that many novice mini-bath owners are concerned about where it is, how often it breaks down, and how often it is serviced. In fact, this type of equipment is much more diverse than is commonly believed. Kripsol and other brands regularly release new models of equipment needed to maintain a healthy environment.

It is worth talking in more detail about how to choose heat and drainage pumps for water, about their repair and installation.

Appointment

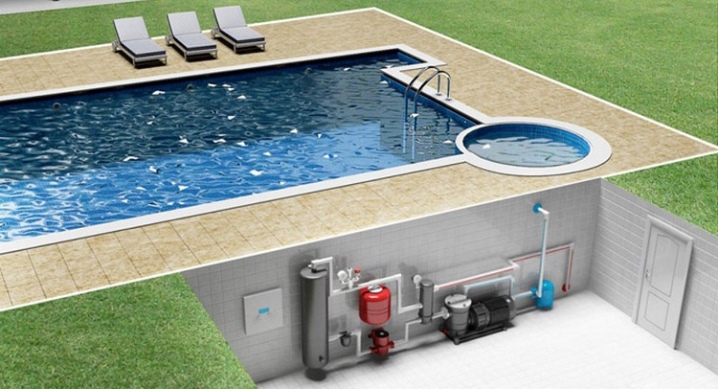

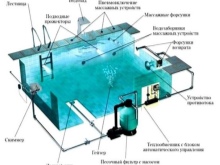

A pool pump is a type of equipment that pumps liquid through a pipeline. It can perform a circulation function, moving the medium in a closed loop, serve for draining or filtering water.

The number of pumps, where they are, how they look, depends on the complexity of the hydraulic system and the volume of pumped liquid. It is also important that the pool has additional functions - hydromassage, counterflow, attractions, to which additional equipment is supplied.

Views

The modern pumping equipment market is filled with a variety of product options that are positioned as necessary components for the operation of the pool. How justified are such statements, which you definitely cannot do without when operating a home bath - it is worthwhile to understand in more detail.

Self-priming

The main type of pumps used in swimming pools. She represents a unit installed outside the pool and maintaining the height of the water column up to 3 m. Such equipment is used to filter water, the pump is usually included in the delivery set along with the hot tub itself or structural elements for its assembly.

However, sinceThe water purification system is not always used... It is turned on only in models with a prefilter (sometimes the option "with a piezofilter" is mistakenly used), in which there is a basket for coarse cleaning of the flow. If it is absent, it is necessary to connect an additional filtration pump to the system.

Self-priming includes and drainage pumps. They use in their work the principle of pumping water with small volumes of clogging. It can be a bottom type of equipment that is lowered into the aquatic environment and does not require the supply of additional hoses. The surface-type electric pump remains outside, from which a suction hose is pulled into the container. Bottom vacuum cleaners can also be used as drainage equipment.

Circulating

For circulation pumps, the main mission is not to purify water. They ensure the movement of the medium, preventing its stagnation, mix cold and warm layers of water with each other, provide a constant direction of the liquid to the filters to improve its purity and transparency.

They are often used as spare or auxiliary, the capacity is determined by the volume and intensity of circulation. In general, it is such equipment that helps to experience fewer problems with the "bloom" of water in the bathing tank outdoors.

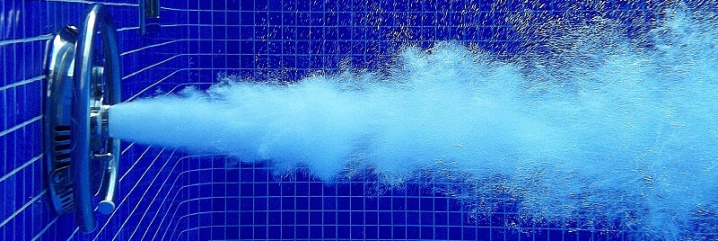

A centrifugal pump, which creates a counterflow in the pool, also belongs to the category of circulation pumps, equipped with suction and discharge pipelines. In home pools, the hinged version is most often used, which makes less installation requirements.In stationary ones, you can use this element as an embedded part, and place the station itself in a separate room. You can also vary the number of nozzles: 1 creates a narrow flow, 2 allows you to make the track wider, a piezo button or a pneumatic button is used to turn on a special water mode.

Filtering

Pumps of this type are usually used in frame or inflatable pools. They are the most compact, easy-to-use, help to effectively fight against pathogenic microorganisms and other sources of problems in the aquatic environment. When sucked into the device, the liquid undergoes mechanical and chemical cleaning, after which it is again discharged into the pool.

There are 3 most popular types of such equipment.

- Sandy... The simplest in design, inexpensive. It uses coarse quartz sand as a filtration substance. The degree of water purification will be sufficient for an inflatable pool with frequent fluid changes.

Maintenance of such a pump is carried out weekly, with backwashing of the silted layer.

- Diatom... An innovative type of pump with a cartridge-type filtration system. Inside it are small particles of fossil plankton, brought to a powdery state.

Such a system copes with deeper cleaning, but the filler periodically has to be replaced with a new one.

- Cartridge. The most durable pump option with replaceable filter units. Mechanical filtration is performed through a polypropylene or polyester barrier. Cleaning is carried out with a regular jet of water.

Thermal

Heat pumps are essential to maintain the optimum water temperature in indoor and outdoor swimming pools. They look almost the same as an external block of air conditioning systems, and in their work they use similar principles, moving not a cold, but a warm environment and generating the necessary energy for heating.

Simple home pools are equipped with air-type heat pumps. They use the principle of air exchange in their work, intensively pumping it with the help of fans.

Inverter electric swimming pool pumps can both pump and drain water, providing heating and circulation without additional effort. Air installations of this type have different capacities, are equipped with reliable heat exchangers, which ensure rapid heating of water to a predetermined temperature. For pools with sea salt, not titanium, but copper versions of the heaters, resistant to corrosion, are used.

Review of the best models

Among the popular models of pumps for the pool, you can select the products of the most famous and respected manufacturers. Such models can definitely be included in the number of sales leaders.

- Bestway 58389... Sand-filled model for outdoor pools. Budget and durable solution for home, summer cottages. The built-in cartridge makes it easy to clean and maintain the filter.

- Intex 28646... Inexpensive sand filter pump for inflatable pool. Belongs to the category of universal, copes with cleaning bowls with a displacement of up to 35,000 liters. There is a built-in function of water circulation, drain, backwash of the system.

This is the optimal solution for use in a suburban area.

- Kripsol Ninfa NK 25. The Spanish brand produces pumps with a capacity of up to 6 m3 / h. They are reliable, functional, do not require complex and time-consuming installation.

- Emaux SS033. A Chinese manufacturer produces pumps with a capacity of 6 m3 / h, equipped with a prefilter. The model is easy to maintain and use, has excellent performance, high reliability, and is sold in the middle price category.

- Behncke DAB Euroswim 300 M. A popular model of a centrifugal circulation pump from a well-known German manufacturer. The complete set already has a pre-filter, a noise suppressor, which reduces the level of discomfort during the operation of the equipment.

This is the optimal solution for use in home swimming pools of different displacement.

The pump is worth higher than its counterparts, it is distinguished by its high performance and quality of performance.

The best pool heat pumps are from leading European manufacturers. The recognized market leaders include the Czech manufacturer Mountfield with its BP 30WS model.

It is designed to work with fresh water, equipped with a rotary compressor, titanium heat exchanger, and operates on a household power supply.

Zodiak Z200 M2 from a manufacturer from France is also noteworthy. This monoblock with a rotary compressor and titanium heat exchanger has a power of 6.1 kW, a capacity of up to 3 m3 / h, suitable for pools up to 15 m3.

This version of the device has a higher cost, but is considered reliable.

The most impressive counterflow pumps are manufactured in Swedish company Pahlen and German Speck. Among them there are both embedded models and mounted, universal ones. The recognized leader of sales is considered Speck Badu Jet Swing 21-80 / 32. No less popular Pahlen Jet Swim 2000 4 kW.

What to consider when choosing?

In order to choose the right pump for the pool, it is important to pay attention not only to whether it is pumping a large or small volume of water. Many other factors are also important, including the ability to manually clean filters and other elements from blockages.

Before buying, be sure to find out such points.

- Appointment. Pumping equipment for outdoor pools differs markedly from installations used all year round. If the water is not planned to be heated in extreme cold, you can do without a powerful heating unit. A lot of waste is easy to avoid if you plan your pool maintenance properly.

- Noise level. For a home bath, it is desirable that it be moderate. The pump is placed near the pool, too noisy unit will spoil the rest, interfere with communication.

- System security level. It is good if the equipment has a built-in engine blocking when operating without water, a network voltage controller. The reliability of the insulation of electrical wiring is also important - for the street it is better to take the option with maximum protection.

- Built-in coarse filter... It significantly extends the service life of the equipment, prevents it from clogging up with relatively large debris.

- Performance indicators. It is quite simple to calculate it for self-priming pumps: the pump must completely pump the volume of the aqueous medium in the pool for up to 6 hours. This is required by sanitary standards. Accordingly, the formula will look like dividing the displacement of the bath by 6. For example, for a bath of 45 m3, equipment designed for a load of at least 7.5 m3 / h is needed, it is better to take with a margin of 2-3 units.

Maintenance and repair

In most cases, installing pool pumps with your own hands does not cause much trouble. To connect equipment for pumping liquids, it is enough to follow the attached instructions, follow a number of simple rules.

- For pressure and filtration models, a waterproofing base must be prepared. When operating indoors, it is important to maintain the temperature in it at least +5 degrees; when placed outdoors for the winter, the equipment is dismantled.

- For the pump to work efficiently, the difference in height between the pump base and the water level in the pool should be between 0.5 and 3 m.

- To reduce noise and vibration during the operation of equipment will help rubber mats.

- The water suction line should be as short as possible. A strong slope of the line should be avoided; it is not recommended to change its direction.

- When connected to a network, it is recommended equip the device with an automatic cut-off, capable of protecting the device from failure in case of voltage surges or short circuits.

- Heat pumps are located outside the pool, on a solid, level base. The maximum pipeline length is up to 10 m.

All these tips help to make pump connection work more quickly and correctly. Of course, each type of equipment has its own subtleties that have to be taken into account, but general recommendations help you quickly find the right solution. When operating pumping systems, certain recommendations must also be followed.

For example, it is imperative to take into account the recommended continuous operation time - usually it is limited to 4 hours with the total number of cycles for starts during the day at 16 hours.

It is imperative to monitor the presence of a sufficient volume of liquid - any blockages, stagnation in the system are very dangerous and can lead to failure of the pumping equipment.

During the operation of a pump for a pool, its owner may be faced not only with the need for thorough water treatment, but also with the repair of out-of-order equipment.

Among the common problems are the following.

- Blocking the flow of water with air... It occurs when changing equipment and if it is located above the water level. In this case, if a circulation pump with a prefilter is used, you need to turn on the equipment and wait until filling occurs naturally (while observing the restrictions on the duration of dry running). Or pour in liquid, and then do short starts for 5-10 seconds. In the absence of a built-in filtration system for the same purposes, you can use the filler hole, the actions continue until water appears, changes in the sound of the equipment.

- Problems with the pneumatic button on the control unit... Since it directly controls the switching on of various types of pumping equipment, water attractions in the pool, the failed part will have to be replaced. With the piezo button, such problems no longer arise, the installation is similar, while the range of its placement can be increased.

- Water does not circulate due to blockage in the system. To clean and unblock the hose, it will have to be disconnected from the system and mechanically "punched" with a special device for plumbing work or improvised means. It is important to handle the flexible liner with care, otherwise tears and cracks may appear on it.

- Filter is dirty, water does not circulate... To clean it, you will have to disassemble the pump of the cartridge cleaning element. To do this, turn off the pump, turn the valve responsible for the pressure release counterclockwise. Then you can open the filter and take out its contents, subjecting it to a thorough cleaning. After assembly, the system can be restarted.

- Water leak. If the pool water supply system is poorly monitored, it can eventually leak at the connections. Most often, water leaks near the inlet, outlet, and where the filter is attached. You can solve the problem by replacing the gaskets, tightening the connections. If only the inlet hose is leaking, the first step is to clean the filter.

By following these recommendations, you can easily cope with the tasks of maintenance and repair of pumps for swimming pools, and return them to service after a breakdown.

In the following video, you will find tips for operating the pool pump.

The comment was sent successfully.