Pool waterproofing: features and types

A large number of people who live in their own houses or cottages dream of having their own pond. The creation of a pool is quite a financially costly business, which is why not everyone can afford to fulfill their desire. But you can do it yourself on your site. True, the reliability of such a design will depend on a host of factors and characteristics. One of them that you should definitely pay attention to is the waterproofing of the pool. Correctly performed water insulation of the pool bowl will make it possible to make such a structure reliable and increase its durability.

Peculiarities

It should be said that no pool can do without such a thing as waterproofing. Without it, it will be just a concrete hole in the ground. The presence of coatings that protect the walls from moisture makes it possible to achieve certain goals.

- Retain water inside the tank. The pool is a container with a large amount of water, which puts quite serious pressure on the walls of this structure. Naturally, pressurized water will seek any way out. Even when it comes to a small gap. And if the waterproofing is not carried out very well, it will definitely find such a gap.

- Finishing protection. If ceramic tiles are used for the interior design of the pool tank, then you should take care that the base where it will be glued is as waterproof as possible. Of course, such a finishing material has some resistance to water. But the lack of waterproofing will simply break the adhesion to the adhesive, which is why the tile will simply fall off.

- Protection of a concrete base. Good concrete, from which various hydraulic structures are usually made, must perfectly withstand prolonged contact with moisture. But using waterproofing mixtures, we create protection, which makes it possible to significantly increase the durability of the leveling layer and the concrete itself. By the way, it must be said here that even the best waterproofing will not help if the technology for creating concrete walls is violated and poor quality material was used. When the capacity begins to collapse - a matter of time.

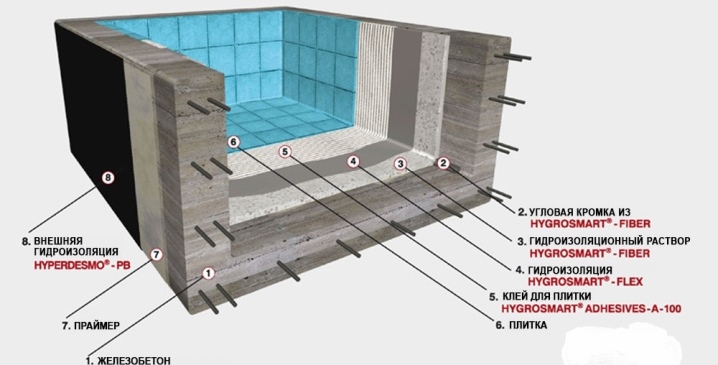

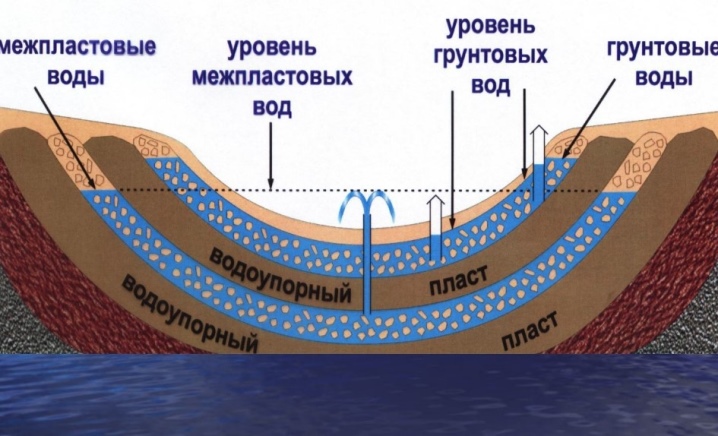

- External protection. External waterproofing is required for those structural elements that are located below ground level. It will not only protect concrete from infiltration of groundwater with dissolved layers, but also become an additional barrier for water so that the soil does not get wet around the perimeter.

In general, as you can see, pool waterproofing has a number of features, and in no case should it be neglected. The better it is made, the better it will be for the whole structure.

And last but not least, this is ensured through the use of high quality materials.

Species overview

It should be said that the waterproofing of the pool is different. For example, it is of two types:

- roll;

- coating.

In the case of the latter, it is applied to the base, which was very well prepared in advance. This type of waterproofing is placed on the inside of the tank.

If we talk about roll, then it is usually used for external waterproofing work. The disadvantage of roll materials is that they do not adhere very well to various types of coatings. For this reason, after laying the material, the seams must be welded, and the edges must be raised in order to connect with the waterproofing agent for the walls of the concrete bowl.

There are also internal and external waterproofing.

Internal

If we talk about this type of waterproofing, then it is needed to protect this structure from the water that will be inside.

If the pool is being made in a building or room, then it will be enough to make only it. A number of requirements are imposed on this type of waterproofing.

The material from which it will be made must meet the following requirements:

- have high strength and elasticity;

- be environmentally friendly;

- do not collapse from exposure to ultraviolet radiation;

- be water-repellent;

- have increased adhesive characteristics;

- well resist destruction;

- have resistance to loads of hydrostatic and dynamic type.

In addition, the layer of internal waterproofing that is under the tiles should be as thin as possible. All these criteria are met by membrane, penetrating mastic and liquid rubber. It is these 3 waterproofing materials that will be best placed under the tiles.

External

If we talk about external waterproofing, then roofing material or an ordinary film is usually used for it.

In some cases, the walls of the pool from the outside are simply coated with bitumen, which was previously melted on fire.

However, experts do not recommend the use of this type of materials for the following reasons.

- Roofing material and film, when laid, form joints. It is simply impossible to glue them together reliably, which is why the seams begin to leak over time. This causes the walls of the pool to collapse, after which the internal waterproofing with tiles will also collapse.

- The weak elasticity of such materials is another drawback. Ground shrinkage and temperature changes have a negative effect on the reservoir in the form of expansions and small movements. And this becomes the reason for the appearance of tears and cracks on inelastic materials.

- These materials have an extremely short term of use. The film can last no more than 10 years, and roofing felt and bitumen-based mastic will begin to deteriorate somewhere in 20 years. That is, after this time, the pool will need to be excavated and waterproofed again.

- Film, roofing material and bitumen very quickly begin to flake off the concrete walls of the pool. The reason for this is a fragile adhesion, which in this case cannot be strong. Such waterproofing will need to be pressed against the bowl reservoir by something, which leads to high financial costs.

In general, as you can see, it is better to use expensive, but highest quality materials for external waterproofing. For example, membranes, deep penetration compounds or liquid rubber.

Protection of this type will effectively perform its function for about half a century. Waterproofing can be two-component, made of the two listed materials. Then she will receive additional reliability.

It is highly undesirable to use liquid glass for waterproofing. When it hardens, it forms a solid film, which is why the issue of cracking the layer of such waterproofing due to temperature changes is only a matter of time.

Material classification

To create waterproofing of pools, a fairly large number of materials are used today. And it will not be superfluous to give their classification and understand how they differ and what properties they have. They are usually classified according to two criteria:

- by the method of application;

- for use.

By application

If we talk about waterproofing materials according to the method of application, then they fall into 2 categories:

- polymer;

- bituminous.

Bitumen used for insulation is a material that results from hot air blowing of tar. A tar is the result of heating the last fraction, which is obtained during oil refining in a vacuum space at a temperature of more than 400 degrees. An important characteristic of insulating bitumen is the impossibility of dissolving in water. When such material is applied to a surface, a highly durable waterproof coating will be created that does not corrode.

In general, the use of this type of waterproofing makes it possible to significantly increase the operating time of the pool and ensures its stable operation even with permanent contact with groundwater.

It should be noted that bitumen is the basis for the creation of roll and coating materials - mastics.

If we talk about polymeric substances, then they include those substances based on polyurethane. When such a material has been applied to the surface, it interacts with air and transforms into a polymer type film, which provides excellent protection against water.

Polymer waterproofing is essentially universal. Its strengths include:

- excellent elasticity;

- durability;

- ease of application;

- high-quality adhesion to all kinds of materials - concrete, brick, glass, ceramic tiles;

- resistance to temperature changes.

There are two types of polymer insulation - sprayed and coated. Usually it is represented by various types of sealants and mastics. With the help of the latter, it is possible to protect hard-to-reach and not very flat surfaces. Sealant is a more viscous substance that can be easily applied to almost any surface. This includes liquid rubber. Polymer-coated waterproofing is an excellent solution for any concrete bowl.

By application method

The materials under consideration also differ in the method of application. According to this criterion, they are:

- roll;

- coating;

- sprayed.

The last group, which includes bitumen and polymer materials, as well as penetrating impregnations, used to form a solid layer without seams... Usually, a two-component or one-component polymer-cement waterproofing is done, using which it is quite easy to seal well not very large pores and cracks, which may be in the concrete coating. For greater efficiency, rubber paint will be used instead of tiles, which will have an auxiliary, but similar effect. Lubricants are inexpensive and can provide really high quality protection to the concrete bowl with minimal labor.

Even a person without experience can apply several layers of mastic with a spatula or brush.

Roll materials include polyvinyl chloride film, roofing material, film membrane. They are usually used to form a protective layer on both sides of the bowl. But when using such materials, seams in the insulating coating cannot be avoided. To cover the seams, materials of this type are usually laid in 2 layers.

By the name of the materials to be sprayed, it is clear that they are sprayed onto the pool bowl.... These include polyurea. Also popular is this type of waterproofing made with polyurethane foam.

The best remedies

As it has already become clear, the water in the pool has an effect not only on the finishing materials of the bowl, be it plaster or tiles, but also on the base itself. For this reason, the materials used for waterproofing must not only withstand moisture, but also be resistant to various types of influences.

Not every material has these characteristics. There are only 3 options for creating really high quality waterproofing:

- membrane protection;

- the use of waterproofing materials of the so-called deep penetration;

- use of liquid rubber.

This does not mean that other remedies will be worse. It's just that these three methods are considered the most effective.Let's talk a little more about them. The use of liquid rubber will be relevant due to its extremely high elasticity, resistance to mechanical damage, and the absence of seams. Such material will be applied either by spraying or by hand. It is better to use the following means to create an internal type of waterproofing:

- silicone composition "Hyperdesmo PB-2K";

- mastic called "Dels BP";

- liquid rubber Trowel Grade;

- 1-component TopCoat AnyColor rubber;

- Roller Grade composition.

This type of impregnation would be an excellent solution.

Various substances from the Litikol company can be used to create waterproofing.

This form produces the following materials:

- mixture for waterproofing Coverflex;

- penetrating waterproofing Osmogrout;

- waterproofing cement type Elastocem Mono;

- substance for creating waterproof concrete Aquamaster.

The use of this type of materials will create a good waterproofing of the pool, significantly extending the life of the concrete bowl.

An excellent solution when creating waterproofing of the pool bowl would be the use of special elastic substances for waterproofing from Ceresit. For example, a mixture with an index CR 66 is designed to protect building structures from moisture, waterproofing swimming pools, basements, showers, water tanks. With a thickness of 2 millimeters, this mixture perceives deformation with an opening width of up to half a millimeter.

In general, as you can see, there is a sufficient number of fairly good materials on the market, the use of which allows you to create a good waterproofing of the pool bowl of the internal and external type.

Which is the best to do?

If we talk about what is the best waterproofing of the pool, then a partial answer to this question was given above. The point was that the most effective solutions of this type are membrane protection, the use of liquid rubber and the use of materials for deep penetration waterproofing. They usually penetrate 45-50 centimeters deep into the walls and the bottom of the concrete bowl, due to which they qualitatively close all cracks and pores of the material. In addition, their use makes it possible to improve the characteristics of concrete and give it additional strength and water resistance.

The use of such materials makes it possible to increase the resistance of the base of the bowl to the effects of low temperatures, and the additional modifiers contained in these materials make it possible to exclude the appearance of mold on concrete.

Truth, these compositions also have a minus - their characteristics at the joints of pipes and concrete pavement are greatly reduced. But here other insulating materials can come to the rescue, which together will make it possible to create an excellent and reliable waterproofing for the pool, both outside and inside.

For pool waterproofing, see below.

The comment was sent successfully.