Lining for a bath: which is better?

The interior decoration of the bath should be approached thoroughly, taking into account all the features associated with high temperatures and humidity of such a room. Today in the modern world there is a huge selection of finishing materials for saunas and baths, which can be based on stone, wood, special types of plastic.

As the practice of experienced craftsmen shows, unconditional preference in this matter should be given to a special finishing material - lining. It has a number of advantages, along with others, due to its qualities.

Peculiarities

- Lining is an environmentally friendly natural material that can be made from various types of wood.

- Any bath or sauna in its building usually contains several rooms, such as a dressing room, a shower room and the steam room itself. These premises differ from each other in their functionality, as well as in the requirements for decoration. Lining is versatile and will perfectly suit any of them.

This material is resistant to high temperatures, water and high humidity.

- An important feature of the lining is its safety for the human body. Places for seating, as well as the walls of the room in the baths should not be scalding. The tree is not able to heat up to high temperatures, making it almost impossible to get a burn from it.

- The lining has high aesthetic qualities, has in its arsenal a variety of design solutions that can please any sophisticated connoisseur with the beauty. To understand this variety, you need to get better acquainted with the types of lining.

Views

The lining is different in design and is divided both by external characteristics and by their qualities. These properties are influenced by its woody component, as well as the type of processing. Depending on these two characteristics, it is divided into classes "Extra", "A", "B" and "C". Let's pay a little attention to each of them.

- Extra class - excellent and the most expensive sort of lining. He, like no other, is perfect for any interiors and various design solutions. This class can be called elite. Manufacturers do everything necessary to prevent any visible defects on its surface. They even use special vacuum packaging for transportation.

The thickness of plates in this class is usually only 12.5 mm. The surface is smooth to the touch and does not deform. This type is perfect for both solid finishing and partial decoration of a certain area of the room.

- Lining of class "A" is not much inferior to the previous type, has a flat surface without visible external defects. The only thing that is allowed is some surface roughness, which is usually not visible to the eye.

- Lining "B" class has various types of defects on its surface, for example, such as wormholes, chips, cracks, grindings. However, their quantitative ratio should not exceed 15 mm per running meter. In addition, this class of lining also admits defects in the end part in its performance, but on one condition - they should not affect the build quality.

- Lining of class "C" - the cheapest finishing material.It looks quite clumsy, because it allows the presence of many defects, such as cores, wormholes, cracks, tarring, rot and even partial absence of knots.

The abutting surface of the grooves of this class of lining can also be in an ugly state, which will greatly complicate the process and affect the quality of its assembly. However, the size of the scrap should not exceed a fifth of the plane of a running meter.

Having figured out the types of material, let's move on to familiarizing the species of wood from which it is made.

Linden

An excellent material characterized by its increased wear resistance and durability. Its excellent resistance to water will not allow microcracks to form on the surface, and will protect against deformation during the drying process. High heat-conducting qualities will also play a favorable role in the steam room, allowing you to quickly and evenly distribute heat throughout the room, and reduce the time for its cooling.

The material has another plus - a relatively low cost with good strength characteristics. Linden scent, as you know, has a calming effect on a person, promotes relaxation, which is a necessary property of the steam room itself.

Pine

When using conifers to decorate the baths, some care should be taken, keeping in mind the internal characteristics of such wood. The fact is that pine has a high resin content, which does not differ in the release of useful essential oils. Rather, on the contrary, the composition of its resin is toxic when excreted abundantly. Therefore, lining made of this type of wood is not recommended for use in paired rooms where high temperatures are present. However, it is quite suitable for dressing rooms and floor decoration, where a low temperature regime prevails.

Aspen

Aspen lining has its advantages. In terms of safety, this material should be given a leading role. The fact is that such wood has the lowest thermal conductivity, so the risk of getting a burn injury is minimized. In matters of durability and wear resistance, aspen lining is not much inferior to linden species.

Alder

Alder is more expensive than the aforementioned samples and there is a reasonable explanation for this. Its properties are even better to use. Its perfectly smooth surface has no defects, and therefore there will be no need for additional grinding and polishing after installation work.

Cedar

The useful qualities of cedar wood have been known for a long time. Due to its healing qualities, this type of wall paneling is gaining more and more popularity. Antibacterial ingredients, as well as a pleasant aroma of cedar essential oils, helps to repel various insects.

A noble pink shade that acquires saturation over time, very pleasing to the eye. With prolonged use, it is able to achieve a beautiful ruby hue.

The only drawback of the breed is its high cost, which most often allows the use of such a lining in elite expensive establishments.

Oak

Oak tree species is the most exquisite and rare of the above, and therefore deserves special attention. Lining made of such material looks truly impressive. By its texture, oak has a very beautiful pattern and a light gray color of a unique shade. Due to the highest strength and density, Canadian oak products are the most durable.

Other breeds

Fir, larch and juniper can also be used as the material for the lining. To create shelves in a steam room, experts recommend glued birch. Differences in species play a role in influencing the durability of wood and wood planks. The difference is also in the aesthetics of the material. You can choose the most suitable option for your home.

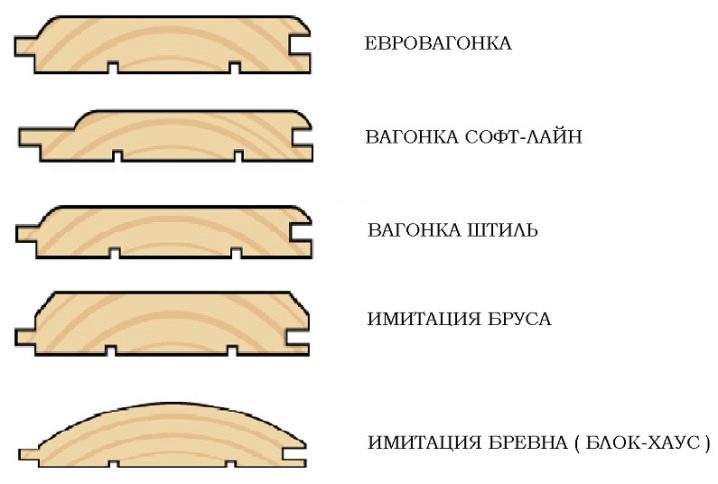

According to the structure and processing of the lining, the following types are distinguished:

- standard;

- blockhouse;

- softline;

- landhouse;

- American.

The so-called euro lining has gained immense popularity. It is easy and quick to work with, it has more convenient grooves for connection, a special ventilation duct and large-scale dimensions - both in width and length.

Mounting

After purchasing the lining, it is necessary to give it a proper "rest" in the room where it will be used. Such rest is necessary for the wood to dry out. The process should last at least a day. If this is not done, the lining attached to the wall can be taken away, which will entail the formation of gaps between its elements.

To increase the efficiency of the bath, a vapor barrier should be installed before installation. Foil or plastic wrap is perfect as a material for it, which is attached to pre-installed slats in a step of one meter. After that, you should proceed to the crate.

In its role, slats with a rectangular section are usually used - 20 by 40 mm. The horizontal step is set between them about half a meter. Such a lathing will ensure the leveling of the surface plane, as well as create a gap between the lining and the wall, providing the necessary ventilation.

The lathing is usually fastened with self-tapping screws or long dowels. It should be borne in mind that the lower bars must be strengthened, retreating 5 cm from the floor, since the plinth will pass in this place. the same goes for the ceiling.

In the gap between the wall and the slats, if desired, you can lay insulation made of mineral wool. However, in this case, do not forget to put another additional layer of insulation on it so that it does not absorb excess moisture. It is necessary to think about insulation at the design stage of the trailer, so as not to lose the usable area.

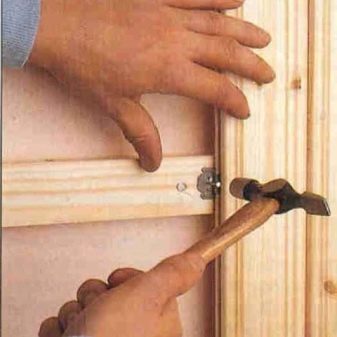

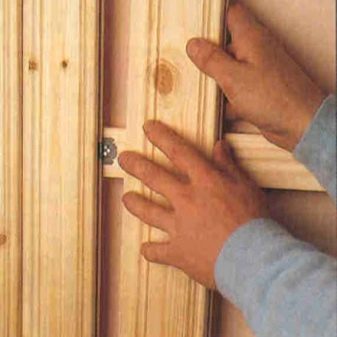

Direct installation of the first lining element should be carried out vertically from the corner of the room. For fastening, you should use a self-tapping screw or a special decorative nail. The rest of the installation process is carried out using nails, self-tapping screws or mounting devices - clamps. It is best to upholster with clamps in order to preserve the appearance of the lining without damage.

By the way, with this version of the upholstery, it is most convenient to dismantle it.

To work with clays, you need a small hammer, as well as small studs. The kleimer is placed in the lining groove and fixed with nails.

After completing these activities, you can proceed to the installation of the skirting boards. In working with them, the clamps are no longer used, and the installation is carried out with nails or self-tapping screws.

Additional processing of lining

After assembly, the lining can be treated with certain compounds that protect it from various insects and moisture, as well as covered with other special solutions that will reduce the risk of ignition. In addition, thanks to such coatings, you can play with its shades, enhancing or reducing the color scheme.

If the wood swells, sticks out or turns black, turns out, it means that it was poorly treated with a special impregnation. The compositions themselves must be of high quality. To reduce the risk of deformation, rooms should be ventilated.

Tips & Tricks

It is worth noting a few general recommendations when using lining as a finishing material for baths.

- In the steam room, you should not use softwood lining. The thing is that such breeds are capable of emitting resins when heated, which does not always have a good effect on human health and can cause allergic reactions in him. Choose hardwoods.

- Study carefully the lining classes in order to avoid deception on the part of sellers.

- When drying the planks, pay attention to the correct positioning. It is better to lay it on a flat surface to avoid deformation.

- During installation work, regularly check the battens to be installed using the building level. This will avoid its curvature in the future.

- When attaching the first element of the lining with a nail or self-tapping screw, drill a hole in it with a thin drill to avoid the risk of getting a crack on the lining.

- Do not stack the boards too tightly to each other, as they, accumulating moisture, can swell, which will subsequently lead to delamination of the planks from the wall.

- When choosing a lining, be guided by the rules of GOST. The state standard has specially developed standards for the safe use of this material.

- It is necessary to buy lining from manufacturers who have positive reviews.

The door to the bathhouse can also be neatly covered with clapboard. Think in advance about safety precautions: the wiring must be insulated. The installation instructions must be strictly followed.

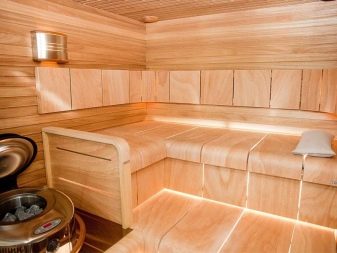

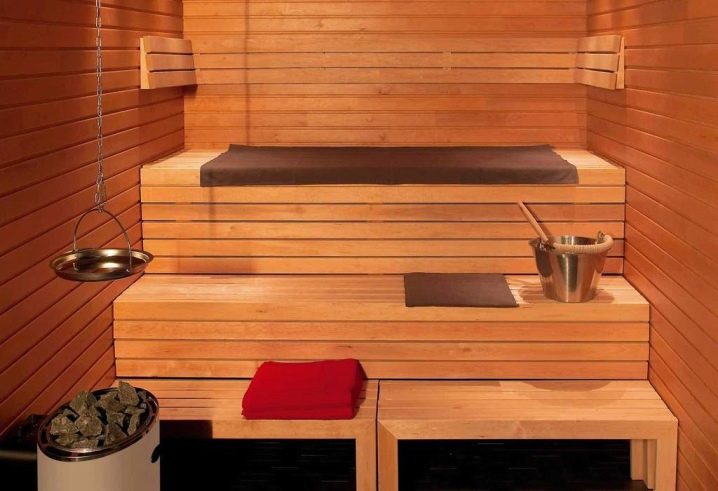

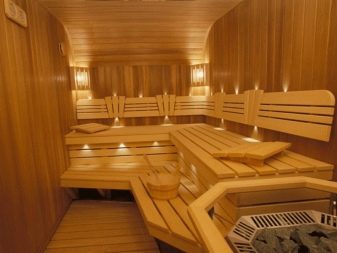

Beautiful examples

The lining in the bath can be mounted horizontally. This way you can keep the warmth inside the room as much as possible.

Sometimes the material is mounted vertically. This is less likely to cause fungus as ventilation is increased.

How to choose a lining, see the next video.

The comment was sent successfully.