Insulation for a bath: selection criteria

Before building a bath, you need to be puzzled by the question of how to insulate it from the inside. It is important to approach the choice of insulating material with great responsibility, since it will depend on the durability of the building, as well as safety and comfort when in the steam room. There are dozens of insulation variations on the market. From the numerous proposals, you need to choose high-quality heat-insulating raw materials that meet all construction requirements.

Peculiarities

A homogeneous wall in any structure does not retain heat well, since it itself is capable of absorbing some of the thermal energy. To reduce heat loss, civil engineers began to create multi-layer structures, consisting not of one, but of several materials that differ in density, porosity and other indicators. Multilayer walls are able to "maintain" the temperature for a long time.

To create such a structure, you cannot do without insulation. The correct choice and correct installation of thermal insulation materials from the inside of a bath or sauna will reduce heat loss and reduce fuel consumption. You should know that not every heater is suitable for warming a steam room. The best solution would be environmentally friendly products that are resistant to high humidity and have bactericidal properties (preventing the formation and reproduction of mold).

The applied thermal insulation materials must differ in the following properties:

- Low thermal conductivity. The efficiency of the material directly depends on this parameter.

- Ability not to deform during long-term use.

- "Combination" with previously selected building and facing materials.

- The presence of minimum indicators of moisture absorption.

- Compliance with sanitary and hygienic requirements and fire safety standards.

In order not to be mistaken in choosing a thermal insulation material, you need to study the advantages and disadvantages of each type of insulation.

Types: pros and cons

For thermal insulation of a bath, a variety of materials are used in different states of aggregation. These can be granular products, fiber products, liquid and extrusion heaters, films.

Manufacturers offer the following thermal insulation raw materials:

- Penotherm - material made of polypropylene, laminated with aluminum foil. For sale comes in rolls. It can be used for both bath and sauna. Differs in durability (service life of at least 50 years), lightness, elasticity, environmental friendliness, affordable cost. With its help in the steam room you can create the effect of a "thermos". The insulation does not emit harmful substances when heated. Among the advantages of a heat insulator, one can also note the possibility of its recycling. The material has no drawbacks.

- Penoplex - extruded raw material, ideal for frame structures or brick structures. The material is resistant to high humidity, easy to install, and durable. The disadvantages of penoplex include its flammability and the release of substances harmful to health when ignited. Due to such features, it is recommended to process it with fire-fighting agents before installing the insulation.

- Izover. The material is supplied to the market in rolls, mats or slabs. Products are made from fiberglass. Suitable for insulating floors, walls and roofs. Isover offers customers non-combustible materials with high heat and noise insulation. The disadvantage of isover is poor moisture resistance.When water is absorbed, the thermal insulation properties of the raw material deteriorate markedly.

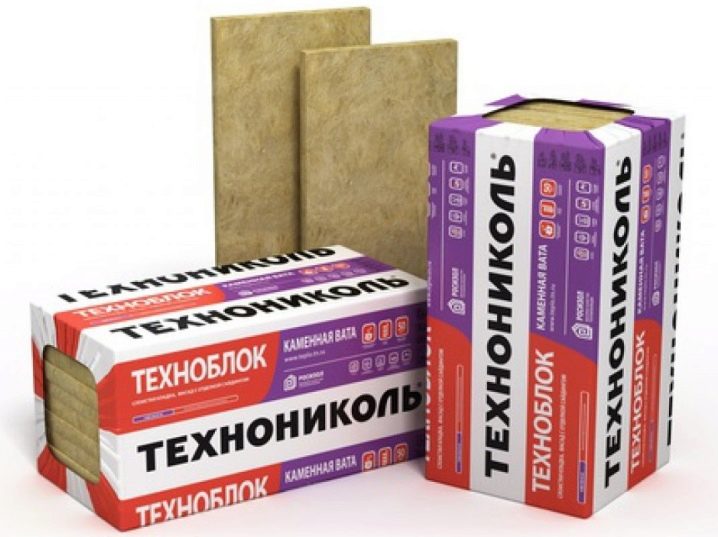

- The "running heaters" also include products Technonikol with the same name of the trade mark. The company produces several types of materials, differing in their properties and technical characteristics. Most heat insulators are made on the basis of non-combustible mineral (basalt) wool. All products offered by the manufacturer have high compressive strength, fire resistance, low vapor permeability.

In addition to the presented heaters for the bath, there are many more heat-insulating materials. They are divided into several groups: non-flammable, natural and foil-clad. Consider the pros and cons of each of these heaters.

Non-flammable

When choosing thermal insulation products for baths, first of all, you need to pay attention to their fire resistance. There are several options for non-combustible materials.

- Minvata. The raw materials are able to withstand high temperatures, so it is advisable to use them when insulating a steam room. However, cotton wool has the ability to absorb vapors and retain moisture. Because of this, its thermal insulation qualities become worse. In order to preserve the properties of the insulation, it is necessary to install a vapor barrier layer when laying it.

- Basalt wool (a kind of mineral wool). Basalt fibers can withstand temperatures of 700 degrees. The products are distinguished by high insulating qualities, durability, water-repellency and shape retention during long-term operation.

- Ecowool - cellulose raw materials, which are advisable to use to improve the thermal insulation properties of the ceiling. Differs in low thermal conductivity. The disadvantages include the ability to absorb moisture (the level of moisture absorption can reach 20%).

- Expanded clay. It is used to insulate floors and ceilings. The material is made from clay and various additives. Such a heat insulator is "afraid" of moisture, so when laying it, you need to take care of an additional layer of waterproofing.

- Foamed glass - an ideal product for thermal insulation of bath structures, resistant to high humidity. The disadvantages include a considerable price for products.

All presented heat insulators are not only non-combustible, but also safe, since they do not emit harmful substances when heated.

Natural

Natural or natural heaters have found wide application in improving the thermal insulation of bathing facilities. Since ancient times, people have used felt, linseed tow and moss as an insulating material between wedges. These products are valuable because they provide natural air exchange. In addition, natural heat insulators have bactericidal properties, they practically do not rot.

Other benefits of natural raw materials include:

- ecological purity and harmlessness to human health;

- long service life;

- low cost;

- small indicators of thermal conductivity.

However, natural insulation is not without its drawbacks. Their main disadvantage is flammability. Of course, the material can be pre-treated with refractory compounds before installation, but because of this, the raw materials will not be completely environmentally friendly.

Another disadvantage is the high risk of damage to the heat insulator by rodents and birds. Insects can start in natural materials, which can "nullify" the thermal insulation properties of the insulation. Also, some of the materials can cause serious allergic reactions.

Foil

To insulate the ceilings of saunas or baths, it is advisable to use reflective materials with aluminum foil. Thanks to a specialized coating, they prevent infrared rays from escaping. Usually foil or reflective insulation is made of expanded polypropylene.Polished aluminum or metallized lavsan is installed on one of its sides.

Moisture resistant foil insulation:

- not flammable;

- has vapor barrier properties;

- durable.

The disadvantages of the material include its high price and "fear" of power loads, which is why you need to be extremely careful when working.

How to choose?

Various building materials can be chosen as the main material for the construction of baths: wood, blocks, brick. It is worth noting that different materials must be used to insulate different buildings. In order to "save" the heat in the steam room as much as possible, it is important to heed the advice of professional builders.

To insulate a cobbled bath, it is recommended to purchase mineral wool slabs, which should sheathe wooden walls from the inside. Before starting work on the insulation of the building, it is necessary to seal the gaps with tow or moss. For insulation of a wooden floor, you can use extruded polystyrene foam, and for the ceiling, take a foil reflective heat insulator.

For frame structures, the best solution would be to buy basalt wool slabs (the density of products should be more than 110 kg / m3). Fiberglass is recommended for the ceiling. For brick, concrete or block saunas, mineral fiber insulation is the ideal choice.

Installation tips

When the bath has been built and the heat-insulating material has been selected, you can start the heat-insulating work. Self-warming of a building is a complex, but quite real process. If you are confident in your abilities, you can refuse the services of professional builders.

Whatever the bathhouse is - wooden, brick or block, the process of warming will be the same. Before starting thermal insulation of a room, you need to think about vapor barrier. This is an important point, since even when choosing a moisture-resistant insulation, there are great risks of its premature deterioration due to the accumulation and penetration of condensate through the protective layers.

To prevent moisture penetration, it is recommended to use aluminum foil. In this case, it is important that the vapor barrier layer is monolithic. A "uniform" surface can be created by gluing the foil with metallized tape.

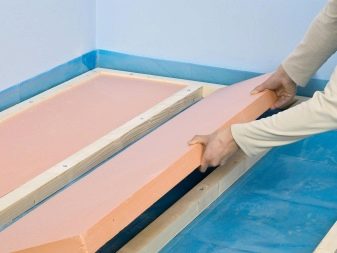

Insulation of floors

According to the laws of physics, warm air in a room always tends upward. Despite this, most of it is able to "get lost" in contact with cold floors. In order to reduce heat losses and accelerate the heating of the bath, it is important to choose a high-quality floor insulation and install it correctly.

When insulating a bath, first of all, you need to start with thermal insulation of the floor. Note that different types of structures require different insulation technology. If the bath is equipped with a solid floor, it is recommended to take mineral wool. The heat insulator should be laid close to the rough floor surface, then it should be covered with a waterproofing layer. After the work done, you can mount the finishing floor.

If the bath has leaking floors, the procedure will differ from the one described above. In this case, you need to dig a small pit (no more than half a meter) and fill it with sand by 5 centimeters. A heat insulator is placed on the compacted sand mass. The laid insulation must be poured with a solution of cement and foam crumbs. The process ends with the installation of finishing on pre-laid wooden posts.

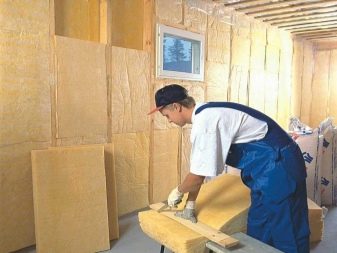

Stages of wall insulation

The sequence of thermal insulation of the walls of baths and saunas is the same as when insulating other objects. The whole process consists of several stages.

- Applying wooden lathing to the wall surface. It is important that the spacing is less than the width of the heat insulator. You can choose mineral wool or basalt fiber as a heat-insulating material.

- After installing the insulation, you need to lay a layer of foil vapor barrier (with a reflective surface inside the sauna). The material is fixed using thin slats. Thickened kraft paper can also act as a vapor barrier.

- The final stage is the installation of the facing material.

It should be noted that for better heat preservation, the bath needs to be insulated not only from the inside, but also from the outside. This applies not only to the walls, but also to the plinth. For its insulation, foam plates or polystyrene foam are best suited. Thus, it is possible to maximally protect the room from external cold, which is especially important in winter. Thanks to high-quality external thermal insulation, the risks of mold and unpleasant odors inside the steam room are reduced.

The fastest and easiest way to insulate walls outside is to install ventilated facades. To do this, the surface of the wall should be covered with a protective waterproofing layer, and then sheathed with lining, siding or boards.

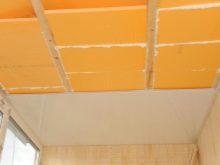

Ceiling insulation

Any steam room needs high-quality insulation. If there is no heat-insulating layer on the way of the warm air tending upward, a lot of fuel will be needed to heat the bath and maintain the optimal temperature in it. However, this is not the only problem. In the absence of insulation on the ceiling surface, condensation will gradually accumulate, which over time will lead to damage to the ceiling.

For the ceiling, it is imperative to give preference to non-combustible materials. Mineral wool or foil products will do. If an attic is provided in the bath, a vapor barrier of thin aluminum sheets must be installed above the heat insulator. Installation of insulation is carried out under or above the rafters. The installed insulating material must also be covered with a waterproofing sheath.

If there is no attic in the steam room, expanded clay can be used as insulation. To do this, they need to fill up the previously laid vapor barrier surface. The expanded clay layer must be at least 25 cm.

Thanks to the choice of high-quality heat-insulating materials and correctly executed interior and exterior decoration, not only a pleasant rest in the bathhouse will be ensured, but also the safety of steam procedures. That is why the selection of building materials and the performance of work should be approached with great responsibility.

For the criteria for choosing a heater for a bath, see the next video.

The comment was sent successfully.