Dressing room: insulation from the inside and finishing

The dressing room serves as a connecting room between the street and the premises for taking bath procedures, whether it be a steam room, a washing room, a swimming pool. How to properly insulate it from the inside, as well as finish it, will be discussed in this article.

What it is?

The functions performed by the dressing room are as follows:

- maintaining optimal temperature and humidity, protection from both adverse outdoor influences and the influence of hot or humid indoor air (a kind of gateway);

- providing rest after bath procedures and before them, creating a favorable microclimate (recreation area);

- creating conditions for changing clothes, storing it under normal conditions;

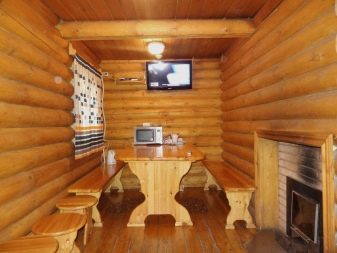

- providing opportunities for collective leisure (the leisure area may include a media area - a music center, TV, etc.);

- provision of conditions for the use of drinks and food, storage of dishes (kitchen block);

- creating a positive psychological atmosphere and comfort (comfortable design and decoration);

- providing a firebox for a bath, possibly keeping a small supply of firewood or other fuel (zone of the furnace firebox);

- storage of accessories (racks, cabinets).

It is not at all difficult to insulate the dressing room with your own hands.

An iron door can make this room warmer.

Finishing materials

The dressing room does not impose such increased requirements on finishing materials, such as a steam room or a washing room. The main requirement is the environmental friendliness and comfort of the materials used.

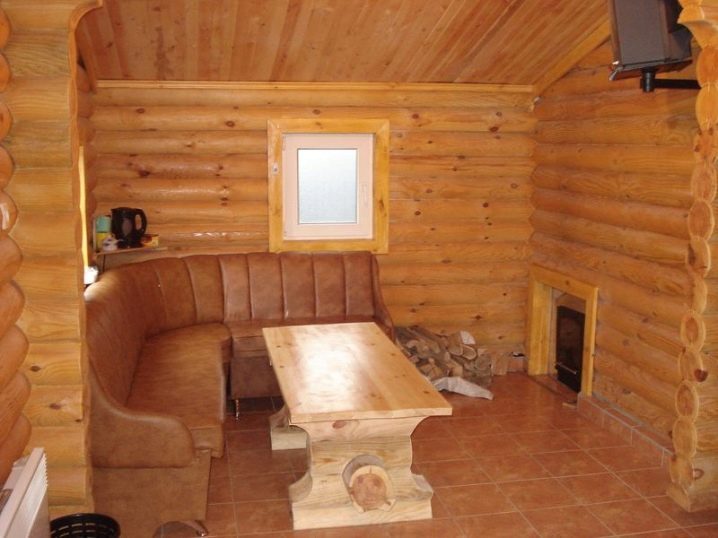

If the bathhouse is built of timber or logs, then usually its interior does not need significant revision. Wood is a classic, beauty, naturalness, environmental friendliness.

If the bathhouse is not built of wood, you should choose a finishing material that is suitable in terms of price, appearance, style, quality.

Walls

For wall decoration are used:

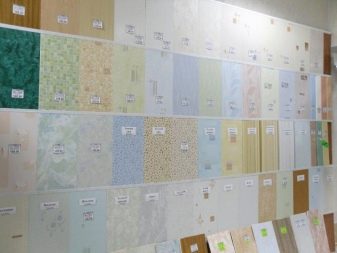

- PVC panels;

- rubber-based paint;

- sheathing board (lining) and its varieties.

PVC panels

Advantages:

- relatively low cost;

- variety of panel colors;

- ease of installation.

Disadvantages:

- low temperature resistance, can not be installed on walls and surfaces with high temperatures;

- unnaturalness;

- monotony, "stereotyped", possible feeling of "cheapness".

It is very convenient to mount such panels. They are installed on flat walls without a frame. There is a wide variety of fittings for the design of joints and corners. The fit is simple with a knife.

The biggest disadvantage is that when heated, the plastic loses its strength and deforms, and can also release toxic substances. Therefore, PVC panels are not used on walls adjacent to the high-temperature zone.

Rubber paint

Advantages:

- strength, elastic surface coating;

- resistance to high levels of humidity;

- painting of any surfaces - concrete, plaster, wood;

- good adhesion to the painted surface;

- resistance to temperature extremes;

- easy application with conventional tools;

- fast drying;

- wide range of colors;

- affordable price;

- health safety.

Disadvantages:

- the rules for applying paint should be followed;

- prepare the surface to be cleaned before painting.

If this type of finish, such as painting, is consistent with the chosen design and the materials used, then rubber paint is perfect. It is durable, does not wear off, does not crack, and is not poisonous.

Paint gives scope for creativity, because you can paint anything. Many people (not professional painters) like to paint, so if you do interior decoration yourself, you can feel satisfaction from the work done and switching to another type of activity.

Lining

Advantages:

- compliance with modern environmental friendliness requirements;

- aesthetics, naturalness, psychological comfort;

- durability with proper processing;

- strength, resistance to temperature fluctuations within certain limits;

- low thermal conductivity, sound insulation qualities.

Disadvantages:

- in general, low resistance (depending on the type of wood) to some types of damage - rot, damage by insects, mold, fungi;

- significant cost when used for the manufacture of high quality material;

- possible shortage of certain varieties and types of lining.

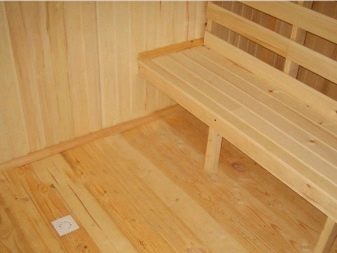

Lining is a planed sheathing board of a certain profile with grooves and grooves with a thickness of 11-22 mm. Depending on the quality, there are grades A, B, C.

For finishing the dressing room, the recommended board thickness is from 14 to 16 millimeters. Installation in rooms with high humidity is carried out on a crate with a step of 60-100 cm.

The lining is of several types.

- Euro lining - a common type of lining, corresponding to the European standard DIN 68126/86, with longitudinal grooves on the back.

- Block house - a board with a rounded front profile. The width of the boards is 90-260 cm, the thickness is 13-50 mm. Imitates log walls, adding additional decorative effect. The disadvantage is the complexity of joining in the corners, the need for individual fit at the joints.

- "American" - boards with different thicknesses on the sides of the groove and tongue, during installation creates an overlap effect, is used for external cladding.

The most suitable material for wall decoration is wood. The wood is natural, creates a beneficial microclimate, has both decorative and high performance characteristics.

Floor

The floor in the dressing room should be:

- warm;

- wear-resistant;

- moisture resistant;

- smooth and not slippery;

- environmentally friendly;

- aesthetic.

Underfloor heating is primarily necessary for health, to prevent hypothermia after a bath. Also, a warm floor creates a pleasant sensation for the feet, contributes to comfort and coziness.

The dressing room is a walk-through room that communicates both with the street and with the bath and shower, therefore, the durability and moisture resistance of the floor is important.

For safety reasons, the floor must not be slippery, since they step on it with bare feet, and for the same reason, it should not have surface flaws - cracks, splinters, protruding knots, etc.

And, of course, to ensure a comfortable stay, the floor covering is selected from environmentally friendly and aesthetic materials.

The main materials for finishing the floor:

- wood;

- ceramic tile.

A classic Russian bath involves the use of wood, but tiles have their advantages. The use of synthetic materials such as laminate, linoleum, etc. is not recommended. They are not environmentally friendly and not durable.

Wooden floor

Advantages:

- naturalness, environmental friendliness;

- low thermal conductivity, comfortable to touch;

- aesthetics.

Disadvantages:

- susceptibility to spoilage under unfavorable conditions and non-observance of the technology of pre-processing and laying;

- exactingness to the choice of boards, the quality of wood and its processing (storage, drying).

Oak or larch is preferred as the flooring material in the dressing room. These types of wood are resistant to both abrasion and moisture.The wood must be of the first or second grade, without traces of fungus and parasites, with a moisture content of not more than 10%. The lags for the boards must meet the same criteria. The timber should be free from significant flaws that could lead to injury and discomfort.

Before starting work, the boards are sanded and treated with antifungal and antiseptic agents, preventing damage to lumber, after which staining is not required. After installation, the flooring is sanded.

Ceramic tile

Advantages:

- naturalness, environmental friendliness, does not emit harmful substances, including when heated;

- high moisture resistance;

- fire resistance;

- abrasion resistance;

- hygiene;

- relative ease of installation;

- a wide selection of flowers and patterns, aesthetics;

- the ability to create patterns.

Disadvantages:

- relatively high thermal conductivity compared to wood;

- fragility, instability to shock loads above a certain force, it is quite difficult to sheathe a room with such material;

- low elasticity, low resistance to deflection and deformation, a rigid base is needed for laying.

Ceramic tiles are a good alternative to wood flooring, especially when combined with heating systems.

For flooring, choose a durable A1 or B1 floor tile that is moisture resistant and non-slip.

The tiles must be uniform and even to avoid installation difficulties. Tile adhesive should be moisture resistant. It is easier for them to cover the surface. Tiles are laid on a flat solid base, for example, expanded clay concrete screed.

Indoor arrangement

This room can be provided with convection heating in winter or other heating can be connected. There must be a steam outlet.

Warming

If the floor is wooden, then the standard insulation technology is as follows:

- below, under the logs, the subfloor is attached;

- wooden elements are treated with an antiseptic composition to prevent damage to wood;

- a vapor barrier film is laid, releasing excess water and protecting the insulation from getting wet;

- the selected insulation is placed (mineral wool, polystyrene, expanded polystyrene, etc.);

- waterproofing material (roofing material or film) is laid;

- boards are laid.

If the floor is tiled, then an expanded clay concrete screed is made under the tiles. Tiles are laid on this screed. However, it is better to install a heating system in order to avoid a cool floor.

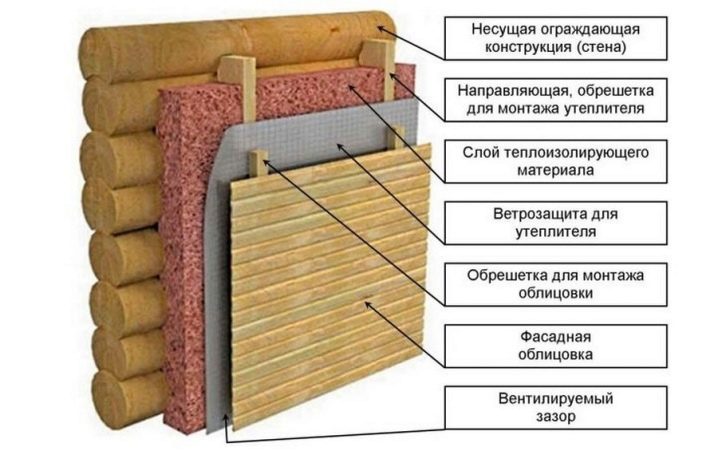

Wall insulation can be done both inside and outside. It is better to insulate the walls from the outside, so they will freeze less and there will be fewer conditions for damping the inner surfaces.

For internal insulation of the walls of the log dressing room, foil-clad polystyrene, expanded polystyrene or mineral wool is used.

For insulation from the inside, lathing bars treated with an antiseptic are attached to the wall with a step of half a meter. Foil polystyrene foam is attached with a stapler to the walls and bars with a shiny layer inside the room. Electrical communications are carried out in a plastic corrugation. A lining is attached on top of the bars.

Insulation from the outside under the facing board is performed as usual: the crate is made using bars with a section of 50 by 50 millimeters, a forty is placed below and above, to which the bars are attached by means of metal fasteners. Mineral wool is placed between the bars, then a vapor barrier is made. A crate is made on top for facing. For outdoor cladding, you can also use different types of siding. This solution is used for brick or other non-wooden walls. For fastening the siding, it is advisable to use specially designed fasteners and accessories.

Ceiling insulation is similar to floor insulation. Between the lags there is insulation, from the bottom with thin strips polyethylene on a foil base is hemmed with an overlap.The joints are sealed with tape and all this is closed from below with a beautiful clapboard.

Basalt wool, a fire-resistant and moisture-resistant material, can be used as a good heat-insulating material. You can also use bulk insulation - sawdust, clay, expanded clay chips, sawdust with expanded clay, sawdust with clay, sawdust with cement.

If the ceiling serves as a ceiling and is the floor for the floor above, then a high-quality floor covering is laid on top of the logs. And if this is a little-used attic, the insulation on top of the log is closed with boards, along which, if necessary, you can move and fold various utensils.

Ventilation

The ventilation system allows maintaining the high-quality composition of the air in the bath room, the correct thermal regime, drying, ventilation. Ventilation ensures air exchange. It is carried out through ventilation ducts. Also, ventilation can be provided by opening windows.

The size of the ventilation ducts is about 15x20 cm. The first channel - supply channel, is located next to the firebox, at a height of less than half a meter from the floor. Another duct, an exhaust duct, is made on the opposite wall at a distance of about two meters from the floor. A fan can be installed in this channel to speed up ventilation. The channels are closed most of the time with appropriately sized dampers.

Heating

The temperature difference in different parts of the bath complex can lead to condensation of moisture in the dressing room, which settles on all surrounding surfaces and things.

The reasons may be a cold dressing room, ventilation that does not provide the required air exchange, as well as a low temperature outside. To create a comfortable microclimate in the dressing room, additional heating is required.

A good way of heating is when the bath is heated by a large stove and one of the walls of the stove, where the firebox is located, is in the dressing room.

If there is a small stove in the bath, then its capacity is not enough for the rest of the premises.

It is possible to arrange the stove in such a way that one of its walls with a built-in water heater heats the next room. The heat accumulated in the boiler is sufficient to maintain the normal temperature.

If the size of the dressing room is sufficient, one of the heating methods is to install a separate heating unit in the form of a stove or, for example, a fireplace. In regions and places where natural gas is supplied, the bath can be heated with a gas boiler. Also, if floor heating is installed in the dressing room, this contributes to maintaining the desired temperature. You can also use an electric fireplace for heating.

Lighting and furniture

There should be no bright light in the dressing room, the bulbs should be closed. The light should be subdued, promote relaxation and create coziness. Therefore, the lighting is desirable dim, unobtrusive. In this case, of course, the level of illumination must remain sufficient. Modern lighting technology makes extensive use of LED lamps. This type of device allows you to create very flexible and original solutions for the lighting design of premises.

The conditions in the dressing room are not aggressive, the temperature and humidity are not excessive, as in the steam room, so standard lamps can be used.

Chandeliers with different types of lampshades are suitable for the dressing room., it is also possible to install wall lamps. If there are places in the dressing room where increased illumination is required, for example, a mini-kitchen unit, a table for making tea, it is worth highlighting local lamps to illuminate such an area.

In addition to lamps, it is worth paying attention to the placement of sockets and switches, since they are not installed in the washing and steam room.

Since the dressing room is also a rest room, this factor should be taken into account in the furnishings. Of course, the size of the room determines a lot. If the dressing room is small, there is a small set of furniture: a table, stools or chairs, a hanger, a cabinet.If there is more space, then it is desirable to have a sofa, a comfortable wardrobe, a shoe cabinet, a mirror. In addition to furniture, it is not prohibited to install a TV set or a music center in the dressing room. The main thing is that these devices do not interfere with the rest and recovery of the body after bath procedures.

If the layout is done correctly, then a bench and a table must be present in the room.

Useful Tips

The bath should be ventilated regularly. Simple wooden furniture should be used for it. Upholstered furniture is not appropriate here, it will quickly wear out and lose its appearance.

Do not overload the interior, the atmosphere should be soothing and simple.

It is desirable that the bath has a high-temperature thermometer and hygrometer, as well as an hourglass.

For information on how to decorate a bath and a dressing room from the inside with minimal costs, see the next video.

The comment was sent successfully.