Shelves in the bath: do it yourself

"Furniture" in the bath does not shine with any decorative delights. Its main goal is maximum functionality and providing travelers with full comfort. It is customary to make any benches or shelves in a bathhouse from natural wood - this is an ideal material for a steam room, which is highly environmentally friendly, easy to handle, and has a traditional and very attractive appearance.

You can easily make shelves in the bath with your own hands. Thanks to the simple design of such a kind of "furniture", even a non-professional will be able to produce it in a short time with high quality and much cheaper than if the shelves were bought in a store or made to order at a factory.

Peculiarities

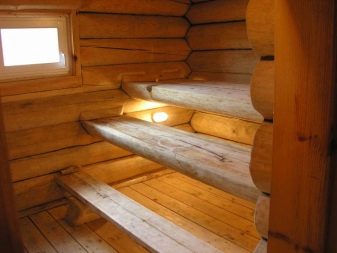

A traditional country bathhouse cannot be imagined without shelves: often multi-tiered, reminiscent of a wide staircase. In another way, such shelves are called canopies. They are an integral part of any steam room.

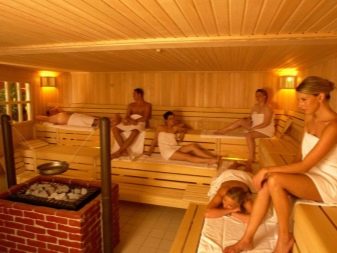

A shelf, or canopy, is a wooden flooring - a kind of elongated multi-tiered bench located along one or several walls of the room. So that you can relax in the steam room, such shelves are made with the expectation that even a large tall person can lie quietly on them. In addition, the multi-tiered shelf allows vacationers to independently choose the most comfortable temperature regime for them.

Sauna shelves can be divided into three types. The most common option are shelves used as benches; they are suitable for both small steam rooms and roomy large rooms. Loungers are not as popular as benches, but they are also found in a variety of baths. And, finally, the third type of bath shelves - chaise lounges. They practically do not differ from beach loungers, and they can be used with equal success both as a couch and as an armchair, which makes them very functional, although far from the traditional design of a bath.

The design of the shelf is extremely simple. Decorative elements are not welcome, as they can cause injury, and they simply knock out of the traditional external design of the steam room. The simplicity and small selection of shelf shapes is easily explained: it is customary to allocate a small room for a bath, which can be easily, quickly and economically enough and without spending extra resources to warm up. Therefore, the most beloved by masters is the ordinary rectangular shape of the shelves.

Material selection

Before proceeding with the manufacture of the shelf, it is worth taking a closer look at the materials, wood, from which they can be made. Not all tree species are suitable for making sauna furniture out of them. After all, they will have to endure temperature drops and, in principle, a very high temperature regime. Add to this the increased humidity, and it becomes clear that few breeds will be able to withstand such extreme conditions.

Suitable breeds must have three main properties. Firstly, such boards must be resistant to ignition (accordingly, the content of various kinds of resinous compounds in them should be minimal), high temperatures and humidity. Secondly, in order for those having a rest in the bathroom to sit and lie comfortably on them, they should not have high thermal conductivity.And thirdly, in order to avoid the detachment of chips and the appearance of splinters in the resting place, the rocks should be very dense and not layered.

Several varieties of trees are most suitable., which can be literally enumerated on the fingers. Most often it is customary to use linden, aspen, larch in the manufacture of shelves. But using conifers (unless, of course, the tree has previously undergone special processing, of which the master is sure) is strongly discouraged. Indeed, due to the resin content, conifers are not only combustible, but also respond to high temperatures by releasing these very resins, which can cause thermal burns.

Linden boards are very easy to process, pleasant to look at, and also resistant to all kinds of stains. They hardly rot or crack, and when heated, they begin to exude a pleasant woody smell. In addition, linden is very easy to process, and it is inexpensive relative to other varieties of wood. The only thing that can be considered a drawback is that with prolonged use in rooms with high humidity, the tree begins to darken.

Aspen boards are generally considered one of the best materials for the production of sauna furniture. This is also a very budget option, which is distinguished by its durability. Initially, this tree is not very knotty, therefore it is not very difficult to process it. Unfortunately, the main drawback of this material is its predisposition to rotting fibers inside the timber, which is not noticeable at first glance. Therefore, you need to carefully approach the choice of such boards.

The most expensive, but convenient and popular material for baths is the African oak - abashi. This material, which is presented in colors of both dark and light tones, has amazing strength and poor thermal conductivity: it heats up very slowly, and therefore protects those resting on abasha shelves from any, the slightest burns, even at very high temperatures. This material, which is important, is resistant to mechanical damage, and hence one of its main disadvantages - the difficulties associated with the initial processing of abasha beams and its high cost.

Sometimes birch boards are also used as a material. This wood is not distinguished by increased strength, it does not survive high humidity, it is prone to rotting and the formation of fungi. Of course, with correct and consistent processing, the characteristics of birch increase significantly, but in any case, it is not recommended to use it in a bath.

Despite the fact that experts advise avoiding conifers in the interior of baths, cedar can be a good material for the regiments. Like all conifers, cedar produces resin, so its boards must be treated in a special way, that is, completely free of any resinous substances. At the same time, the cedar will not lose the pleasant smell of natural wood. It is resistant to decay processes, strong and durable, and its surface has a peculiar woody pattern.

Preliminary removal of resinous elements will allow using any coniferous wood for the shelves. If the owner is not afraid of the difficulties in finding properly processed boards, then the furniture can be made from spruce or pine. However, in no case should the preliminary treatment be neglected, otherwise, under the influence of high temperatures, the minerals and resins contained in conifers will begin to literally flow out of the boards in the most literal sense.

Larch shelves are often quite a profitable solution. It almost does not emit resin, has a pleasant sweetish smell and a very beautiful wood pattern. The only drawback is its high thermal conductivity: it will not be easy to sit on such a shelf in a hot steam room.

The wood pattern itself is a great decoration for the steam room.so no paint is used for the shelves. Moreover, when exposed to high temperatures, paint can begin to flake off and release toxic substances. And in order to protect wooden products from the formation of fungus, mold and decay processes, you can use a variety of water-based impregnations: they are resistant to high temperatures and perfectly protect the wood.

The main requirement that applies to all varieties of trees, whichever is ultimately recognized as the most preferable: there should be no knots on the selected material or they should be removed without the danger of weakening the strength of the structure.

In addition, it is very important to make the correct calculation of the selected material. The minimum cross-section of the timber that will be used to create the supporting frame of the future shelf should be 50x70 mm. Boards that are planned to be used to connect parts of the supporting structure must have a cross section of 20x80 mm or more. The thicker the timber is, the better, because the more weight it can withstand, and this is very important for multi-tiered structures. For flooring, thinner and narrower boards with a thickness of 10 mm or more are chosen.

Sizes and shapes

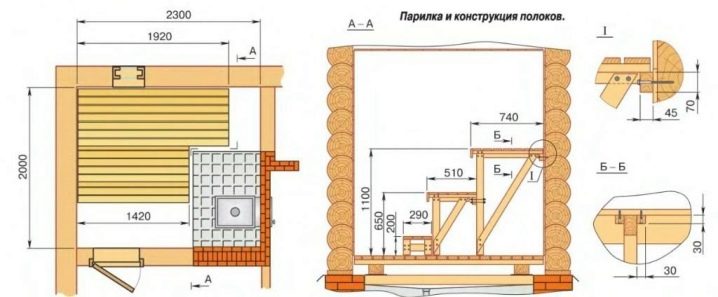

The dimensions of the shelves depend, of course, on the size of the room, which it was decided to take as a bath. For a steam room, complex tiered structures in three steps are often chosen, however, a traditional Russian steam room should have two rows of shelves. In addition to tradition, this is the simplest and most convenient option in order to build it yourself.

In general, the size of the shelf is determined depending on the average height of the bath visitors.

Height

The minimum height of the room in which the steam room is located is 210 cm, otherwise the formation of steam and heating of the room may not flow correctly. The shelf (or its middle part, if we are talking about a multi-tiered structure), in turn, should be located approximately at the same level as the thumb of the hand down. Consequently, its average height will be about 80 cm.With regard to the upper tiers, the distance between the uppermost shelf and the ceiling should not be less than 120 cm: this will provide the visitor with a sufficient amount of space, regardless of whether he will enjoy bath procedures while sitting or lying down. ...

In some compositions, the height of the shelves themselves is determined by slightly different values. So, the lower tier from the floor must be at least 30 cm in order to provide the furniture with maximum natural ventilation. It is better if the average height of the shelves is on average 40 to 60 centimeters, although in the end it depends on the number of shelves.

Length and width

According to the standard, the minimum long shelf, which should provide comfort for a person lying on it with legs bent at the knees, is about one and a half meters. If the size of the room allows, then the length of the shelf increases to 1.8 m: this size will allow the resting person to lie down without bending his legs. But each person has his own height, therefore the optimal shelf length is considered to be 220 cm.

The minimum shelf width is 40 cm. As a rule, such dimensions have a shelf located on the lower tier. It is very rarely used for sitting, mainly, its purpose is to serve as a footrest for a resting person. But if necessary, the lower shelf can become a place where you can cool off perfectly after the heat of the upper tiers.

The most popular bench seat size is 60 cm. This width allows you to sit comfortably in the sauna, but, unfortunately, it may not be enough for comfortable lying. Therefore, the most comfortable width is 95 cm. On such seats, a vacationer can sit across the shelf, legs tucked in, or can lie quietly.

The dimensions shown here are usually sufficient for a tall and large person to sit comfortably on a shelf. If the room allows the bath room, then the furniture can be large - in the end, it all depends on the individual needs and wishes of the owner of the bath. Another thing is that it is categorically not recommended to take sizes smaller than those indicated, because in this case the shelves will be simply uncomfortable.

After the main dimensions of the shelves have been determined, you can proceed to consider the various forms of this design.

Stepped canopies - This is perhaps one of the most popular types of furniture for a steam room. The shelves are arranged along one of the walls in several tiers - usually in two or three tiers, so that the degree of heating increases with increasing height. The uppermost tier should be located above a heating boiler or traditional stove, but at the same time the above distance of 120 cm should remain between it and the ceiling to ensure maximum comfort for the seated person.

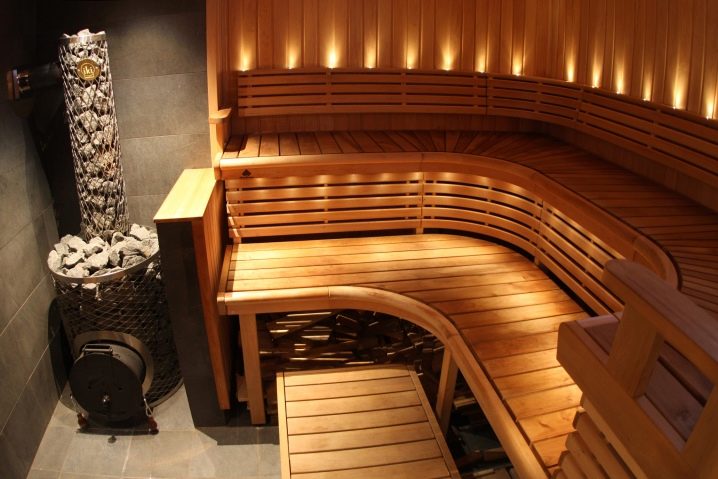

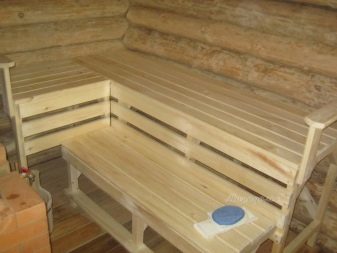

Corner or L-shaped curtains - this is also a fairly common version of the interior composition of bath furniture. Wooden shelves are located on one side opposite the heating boiler or stove, and on the other on one of the free walls. The height of such shelves can be selected individually, therefore this is the most successful option for small rooms in which functionality must be combined with space saving.

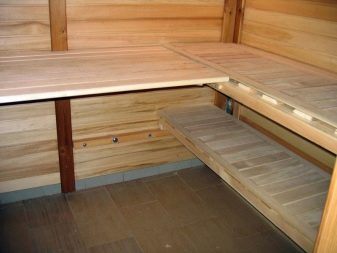

Coupe canopy - this is not the most popular design option for the interior space of the bath, but in itself it is very interesting. In addition, such a composition is spatially extremely beneficial for small spaces. Two shelves are located opposite each other - just like in ordinary compartment carriages of trains. Just like on trains, the upper shelves can be made folding, this will also help to save space.

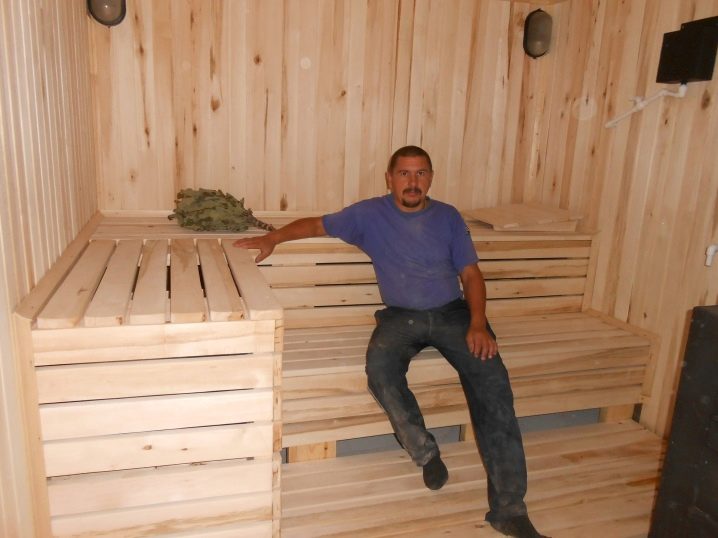

Usually, the frame, which subsequently needs to be covered with floorboards, is constructed from support posts, which resemble the peculiar legs of a bench, connected by jumper boards. However, the shelves can be made without legs - then the main support will be on the walls to which the furniture will be attached.

The flooring itself consists of densely packed and carefully polished planks, the back of the seat is built on approximately the same principle. The distance between them should be from 1 to 2 cm. An interesting and beautiful solution, by the way, will be the installation of a multi-colored backlight in the gap between the boards.

Sometimes, separately from the bed, a special, most often removable, headrest is also made. This wooden device gives the opportunity to the resting person to sit on the couch with true comfort, allows you to relax the muscles of the spine and neck. The design of the headrest itself is simple and does not contain many elements: if you wish, you can also assemble it yourself along with the shelves.

Multistage

At first glance, the arrangement of the shelves may raise some questions, for example, why they are in most cases a multi-stage design.

The reason is, in fact, very simple. When heated, water vapor and hot air rise, while the temperature near the floor is much lower. Thus, each user will be able to independently choose which temperature mode it is more convenient for him to be in: at the bottom, where it is not so hot, or at the very top of the steam room "pyramid", where the temperature is highest. Therefore, if the owner of the steam room decided to make shelves with his own hands, then it is strongly not recommended to retreat from the usual stepped structure.

It is worth noting that in small steam rooms, the lower tier is often located almost at floor level, which allows you to create natural ventilation and make it the most effective. It is also important to remember that the upper tier will be made wider than the lower ones (so that it can be used as a couch), while the distance to the ceiling from the couch should not be less than 100-120 cm.

Location

After the dimensions of the future shelf are determined, you can start planning the location of the bathroom furniture. It is worth remembering that, for example, in a traditional Russian bath it is customary to take a steam bath while lying down, and the shelves consist of one or two tiers. Another thing is the Finnish sauna, in which visitors, as a rule, take a steam bath while sitting. There should be at least three tiers, which means that the distance from the lower tier to the ceiling should be much greater.

A correctly drawn up diagram before starting installation work should greatly facilitate the work of the master. and later will allow those who have a rest in a sauna or steam bath to enjoy the steam room with maximum comfort. On the diagram, it is worth displaying all the dimensions of the room, and also note where the equipment, door and window openings are located.

It is worth taking into account many nuances, such as the fact that the curtains cannot be installed under walls with windows, because due to the hot steam and high temperature, the glass can crack and injure vacationers.

The shelves can have a kind of frame legs, on which the flooring will be stuffed. However, this is not a prerequisite, but only one of the options. You can make shelves without racks, then the wooden frame will be attached directly to the wall.

It is important to remember that the shelves should never fit snugly against the walls. After all, free air circulation is very important for wooden bathroom furniture, which provides the tree with full drying and protects it from rotting processes and the formation of fungus and mold. Therefore, during the installation process, a gap of about 10 cm is left between the flooring and the wall (previously pieces of timber are attached to the wall, to which other frame elements are subsequently attached). The self-tapping screws, with which the fastening is made, should be carefully sunk into the wood so that their caps do not remain on the surface.

This is not to say that the options for the shelves are very diverse, however, if necessary, depending on the size of the bath room, you can choose the most suitable furniture. For small spaces, for example, space-saving options can be found. Retractable shelves, which are made in the manner of shelves in trains, will do. Another option is folding or pull-out shelves. When assembled, they look like part of a wall and take up almost no space. There are also removable shelves, which, if necessary, can be brought into the steam room and put back in place, or can be removed.

Step by step guide

As already mentioned, the shelves are not at all difficult to make with your own hands. It is enough to look at the approximate drawings, grasp the general principle and draw up your own scheme, taking into account the dimensions of the bath room.

In order to process the source material and build the desired structure from it, you will need to stock up on a certain set of tools. It should include a tape measure, a hacksaw for wood, a hammer and a mallet, a drill and a screwdriver, a chisel. Wooden nails are preferable for fixing the flooring. After all, metal nails will inevitably heat up and can ruin all the pleasure of vacationers. You can, of course, fix the boards with screws on the back of the structure, but this is quite difficult, unreliable and, moreover, requires a very accurate calculation, which a professional may not be able to make.

The number of supports required for the frame that will be able to withstand the finished shelves is determined depending on the final thickness of the wooden planks. So, if it was decided to take a board 22 centimeters thick, then the supports will be placed at a distance of 60 centimeters from each other.

Adequate wood should be procured according to a drawing prepared in advance., the tree itself must be of high quality, not have cracks, traces of decay and all kinds of chipping and pods - the boards must be planed and sanded.It is recommended to take wood of the same species for the support posts of the frame and flooring.

The thickness of the flooring boards is selected individually, depending on their width. The best option is when the thickness of the board is four times less than its width.

The tree itself must first be carefully prepared: the material should not have clearly visible defects and any defects, knots, cracks and chips. In addition, it is customary to take wood of the same species for the frame and flooring.

There are several options for assembling a multi-tiered shelf, they do not differ much from each other and follow general principles. Below is just one of them - a traditional rectangular shelf.

Frame fabrication

The frame in the case of a shelf performs the most important supporting function; it is the base on which the flooring made of similarly finished boards of fixed or removable flooring is fixed. These support bases in appearance and in their purpose resemble the legs of an ordinary shop.

To make the frame, a large wooden bar is used., the size and section of which is determined in each case individually. However, most often, in order to assemble the frame of the future shelf, it is advised to take a dozen pre-prepared beams with a total section of 5 by 7 cm, as well as (if it was decided to make a shelf with legs) 5 boards that will act as racks.

These support legs must be installed in a vertical position and held together by rows of cross braces. Sometimes the frame can be equipped using the staircase kosour method, and a very rare option is the installation of bath shelves without supports, immediately attaching them to the wall (as a rule, this is typical for Finnish saunas or baths built using similar technologies), and the seats and sun loungers for to this, they look like shelves and sunbeds attached to the walls, found in train carriages.

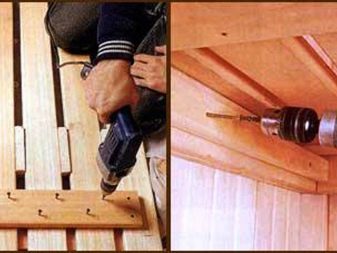

Mounting

After the base of the frame is prepared for installation, it is time to directly attach the structure to the wall of the bath. The benches must be fixed with the obligatory observance of a gap of about 11 cm.

First, the frame of the upper tier is assembled. It is not forbidden to use self-tapping screws so that the frame does not fall apart. Then the first of the rows of bearing racks is attached to the wall, the distance between them is from 60 to 85 cm. At the very top of the bar, a "step" is formed so that fastening can be made "into the lock".

Opposite the bearing supports, a second row of racks is installed, and their tops are united by a transverse beam. For reliability, the structure is assembled with metal corners, and then the supporting supports are "tied" with boards. The next levels are created in a similar way.

For flooring, thin, narrow boards are usually taken. This will provide them with the ability to quickly dry out after using the steam room, which means once again protects against possible rotting.

Installation

Finally, when the frame of the future shelf is assembled, it is time to install it in the bath room. Previously (to provide the shelf with better stability and additionally protect it from moisture), special rubber gaskets are placed on the lower parts of the bars.

Then it is time to install the flooring boards on the frame. You should start attaching the base for the seats from the bottom tier of the frame, while leaving small gaps of 1 to 2 cm between the boards.This is necessary to drain excess condensed water and provides free air circulation inside the wooden shelf, due to which the structure will dry quickly, and the possibility its destruction due to internal decay processes caused by high humidity will be significantly reduced.

It would be preferable to fill and fix the boards to the frame with wooden nails or pins.If, nevertheless, nails or self-tapping screws are used, then they must either be located on the inner side of the flooring, or they must be "sunk" in the wood, deepened by a few millimeters to prevent thermal burns for vacationers, which can ruin all the pleasure of bathing procedures.

Not always, but the vertical space between the floor and the seats of the shelf can also be sheathed with rows of boards. However, it should be borne in mind that although this design looks attractive, in fact, it will only complicate air circulation and complicate the cleaning process.

To ensure the most efficient drying of the seats, you can give preference to removable structures. Such a loose flooring serves as both a seat and a couch. It is easy to remove it from the established place and take it out to dry. The same principle is used to make seat backs, headrests - a kind of bath "cushions", as well as all kinds of devices that help the bather to take the most relaxed position, for example, placing his legs at the level of the head, or even higher.

Treatment

The final stage will be the processing of the resulting shelf with special compounds that will make it more comfortable to use, as well as provide it with a longer service life. It is generally accepted that in a traditional steam room, wood should not be processed in principle, it should be carefully sanded. Indeed, with good ventilation, there may be no need for additional strengthening of the wood fiber, but extra insurance will never hurt, but it will be able to guarantee the furniture a long and high-quality service.

The shops first of all (in fact, many craftsmen recommend doing this procedure with the boards at the very first stages of preparing the frame in order to soak the tree from all sides) must be impregnated with powerful antiseptics. After all, constant contact with humid and very hot air will inevitably contribute to the destruction of the tree. In addition to rotting, mold and fungi and many harmful organisms can develop on the tree.

One of the impregnation options can be natural impregnations, for example, plain linseed oil turns out to be the most budgetary and affordable option.

Antiseptic agents are often used as impregnations., which give the wood moisture resistance and impregnate it through and through. At first glance, an unexpected solution may be the use of bleaches: these special compounds not only protect the wood, but also return it to its original color in the event of darkening. In addition, there are also special formulations intended for direct use in the sauna.

However, in no case should you use chemicals and varnishes as an impregnation, and you should also not paint the wooden flooring with paint. In conditions of high humidity and constant temperature changes, such substances will inevitably begin to decompose and release a variety of toxic substances. In addition to the unpleasant smell, which can turn the steam room from a resting place into a real torture, these substances can cause headaches and allergic reactions.

Naturally, before applying any reinforcing composition to the tree, the boards must be carefully sanded with sandpaper, cleaned of dust and debris left after sanding, and only then proceed to impregnation.

Care Tips

The first and most important rule that should be strictly observed is the mandatory drying and ventilation of the room after each session in the steam room. This will help protect wood furniture from the harmful effects of excess moisture. By the way, the sauna stove will also help to dry the room, if, after the completion of the water procedures, it is left working for a while.

When airing the room, it is worth opening all doors and windows., while covering all containers with water and tanks with lids.

A bathhouse is a room in which, like in a bathroom, it is necessary to maintain cleanliness and carefully monitor internal hygiene. Of course, high temperatures protect the steam room from the appearance of all kinds of microbes and bacteria in it, but they are not able to protect the room from the appearance of dirt. Regular cleaning cannot be avoided. It will be necessary to wash off the remnants of dirt remaining on the shelves after the procedures, traces of condensation.

After the end of the bath procedures, it will not be superfluous to wipe the surfaces with a dry toweleven if there is a backlight. This will not remove moisture that has managed to be absorbed into the wood, but will greatly facilitate the drying of the outer surface of the shelves, which means it will speed up the drying inside the wood.

At the same time, given the specifics of the bath room, that is, its mostly wooden design, it is impossible to use chemical cleaning agents in the steam room. The best option is simple laundry soap. It will be useful to use soft brushes. If there is heavy dirt on the wood that is not easy to remove, you can use sandpaper.

Also, in order to better protect the internal fibers of the boards from wood, it is necessary to re-impregnate the wood with special compounds, because over time they can evaporate.

How to make a shelf for a bath with your own hands, see the next video.

The comment was sent successfully.