Frame bath: the pros and cons of designs

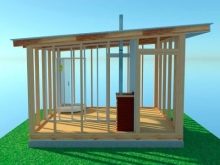

Frame construction is gaining more and more popularity among lovers of bath procedures and owners of personal plots. The construction of a frame bath is an excellent option for those who are not able to give away a lot of money, but want to find a building on the site that, in terms of basic parameters, will not be inferior to similar more expensive projects. In addition, frame baths have a rather pleasant appearance, which, with the help of external finishing, can be made very original and aesthetic. Let us consider in detail the features of all stages of the construction of a frame bath, the subtleties of the selection of materials for construction and current design trends.

Advantages and disadvantages

The construction of a bathhouse on the basis of a frame guarantees the speed of construction, because the principle of construction is quite simple. There are a number of other advantages to wireframe technology.

- The construction will turn out to be very budgetary. This is possible due to the availability and low cost of materials.

- There is no need for a strong foundation. A lightweight version will suffice.

- The room heats up quickly. This is possible due to the low thermal conductivity.

- All communications can be carried out inside the walls. This preserves the aesthetic appearance of the building.

- The opportunity to use the bath immediately after the completion of construction. And all thanks to the lack of shrinkage.

- All materials used are environmentally friendly. Steaming is really useful here.

- There is no need to use construction equipment. But renting one can be very expensive.

- No special skills are required for the independent construction of a frame bath. Even a beginner in this business will master the installation.

Construction can be carried out at any air temperature and weather. Climatic conditions will not affect the process in any way.

In the absence of serious mistakes in construction, such a structure will have a long service life. The main thing is to follow the instructions.

- The very method of construction already suggests that such a building is easy to repair. You can replace one of the modules and this will not negatively affect the other module or the entire building as a whole. If desired, the bathhouse can be made mobile (transportable), but few people resort to this method.

All these undoubted advantages contribute to the growing popularity of frame baths. True, they also have a rather tangible drawback: during precipitation, moisture can penetrate the bars.

Careful observance of some rules will help to avoid this.

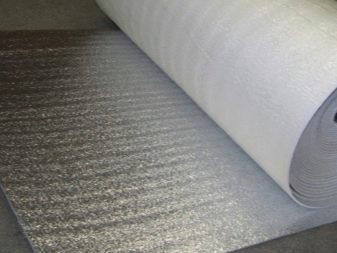

- The use of thermal insulation during construction is essential. It allows you to retain heat for a longer time, promotes tightness and does not allow moisture to penetrate. Mineral wool or fiberglass are good insulating materials.

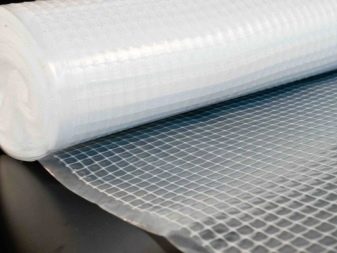

- Vapor barrier equipment will help to avoid condensation and extend the life of the wood.

- A simple type of foundation (pile, columnar) is ideal for arranging on dense soils.

Having familiarized yourself with the main features of the frame structure, you can start designing the future bath.

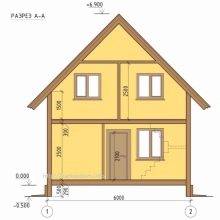

Projects

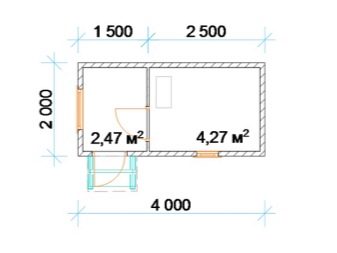

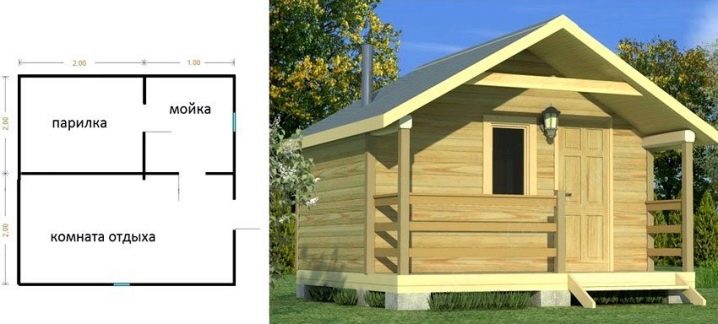

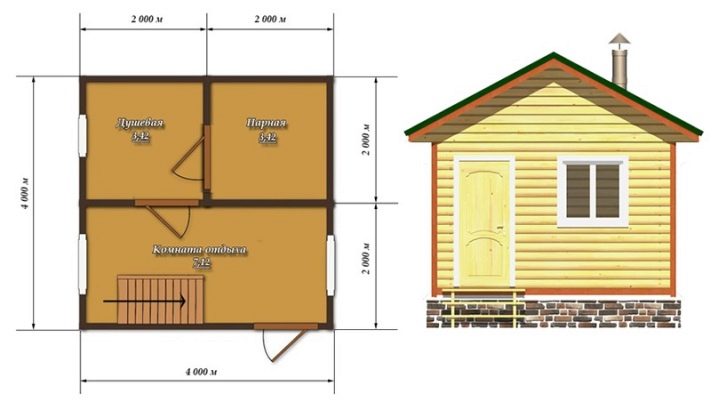

Options 2 x 4, 3 x 4, 4 x 4 m

Starting the construction of such a small bath, you need to be able to use all the internal space as efficiently as possible. Such mini-baths are often built on plots where it is necessary to save territory or as an extension to the house. At the same time, no more than two people can take a steam bath in such a small bath.

In the finished project of the future bath, the number of rooms should be detailed (steam room, shower room, dressing room, pool, etc.). Typical 3x4 bath designs include separate rooms for the steam room, relaxation area and shower room. For heating, a boiler or wood stove is often used.

Such small buildings have their own merits.

- The ability to save on building materials. A standard timber has a length of 6 meters, which means that it can be simply cut in half (if the wall is 3 meters long), leaving virtually no waste. Or into 3 parts with a wall length of 2 meters.

- Such baths are built quite quickly. With a finished project and drawing, you can complete the work in 2 weeks.

- Saving on the amount of material will allow you to focus on its quality. Good wood with high-quality impregnation will last for many years.

When planning the construction of a bath, it is worth remembering that any new construction on the site must be registered in the cadastral register.

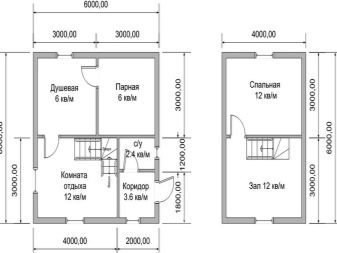

Projects of a 6x6 frame bath with an attic

If the size of the site allows you to build a luxurious spacious bath, why not do it? Especially for those who not only love to steam themselves, but also invite friends.

Baths with an attic are often designed so that a staircase leads from the rest room to the attic floor. The advantage of a two-story building is that the second floor gives a lot of additional space, while the costs do not increase much, because the bulk of the costs goes to the construction of the foundation.

Design

The last stage in the construction of a summer cottage is internal and external decoration.

It is clear that it is performed to the taste of the owner, but there are some universal rules that are better to follow.

- The inner lining of the bath cannot be painted. When heated, the paint gives off an unpleasant odor and harmful substances.

- It is better to start the inner cladding six months or a year after the end of construction. During this time, the building will naturally shrink.

The main methods of exterior decoration are plastering, siding or clapboard made of coniferous trees, block houses, tiles. Thermal panels and facing bricks are less commonly used.

Absolutely all materials that are used for interior decoration of a bath must have a number of characteristics:

- resistance to moisture, hot air and direct contact with water;

- in no case should the material release toxins under the influence of high temperatures;

- strength and long service life;

- environmental friendliness.

Naturally, the most common material that combines all of the above characteristics is wood. It easily absorbs moisture and dries quickly, is absolutely safe for humans and has its own unique smell (which everyone has long associated with bath procedures).

Next, it is worth deciding on the type of lining, of which there are many. After all, if you choose a low-quality lining, it can collect water and swell. Or, conversely, decrease in size, forming cracks (this is possible when buying a raw lining).

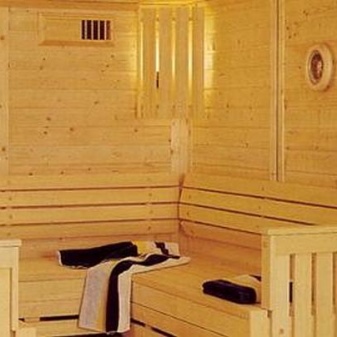

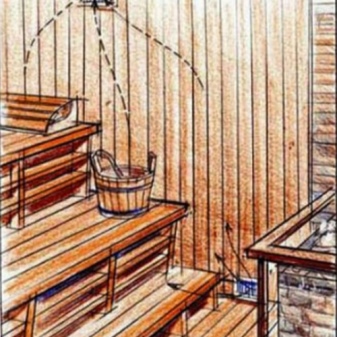

Steam room decoration

Traditionally, deciduous trees are used for the interior cladding of the steam room. They do not emit tar when heated, do not get hot and dry very quickly. Consequently, the appearance of fungus is almost excluded.Often saunas and steam rooms are finished with ash, which is known for its durability. In addition, this tree has a very beautiful interior design, which will give the room an aesthetic appearance.

Alder is also quite popular for interior cladding. And it is no coincidence: the tree does not absorb odors and has a natural unusual color (brown-pink). Foreign manufacturers of saunas very often decorate them with alder.

Washroom finishing

Experienced builders advise to sheathe the sink with spruce clapboard. It has a beautiful bright orange color and is moisture resistant. But there are no strict rules here, so you can choose from many options: tiles, moisture-resistant fiberboard, drywall.

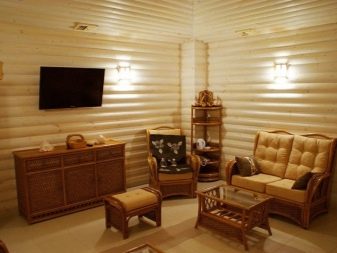

Restroom decoration

This is perhaps the only room in the bathhouse for which design comes first, and then practicality and functionality.

The only requirement for the design of the rest room is the resistance of furniture and decor elements to high temperatures and high humidity.

Traditionally, the decoration is made from environmentally friendly materials (it will not be very pleasant to come from the steam room to a room with a solid synthetic design).

The most logical thing would be to decorate in ethnic style. It includes wooden furniture, lace curtains, a samovar and other attributes of ancient Russian culture.

Less often, the recreation room is decorated in minimalism or in a Scandinavian style.

For those who are very fond of decorating rooms on their own, but do not know what to choose for a bath, there is an excellent solution - a homemade stained glass window. With the invention of colored adhesive film, stained glass ceased to be the art of the elite, and below we will describe in detail the process of its creation.

The technology is ridiculously simple - the colored film is cut into pieces (these can be certain characters, geometric shapes or abstractions) and glued to the window. Thus, a beautiful imitation of colored glass can be obtained. Lead tape can be glued to the joints between the glued shapes. Such a stained-glass window has a huge variety of variations, does not require large manufacturing costs, increases the strength of the glass and serves as an original design element.

Followket to get acquainted with the step-by-step scheme for creating an original stained glass window. Thinking over the design for different rooms in the bath, you should pay attention to the correct organization of lighting. The light should not be too bright, because initially people come to the bath for relaxation and rest. But soft and diffused light will perfectly cope with the function of calming and relaxing visitors. Therefore, it is worth abandoning devices for lighting with high power.

Often, lighting is arranged using small bulbs that are evenly spaced throughout the room or around the perimeter of the ceiling. LED bulbs are perfect - they provide high-quality warm lighting, providing a minimum load on the electrical network.

Materials (edit)

The calculation of materials must be made even at the planning stage of the bath. Having decided on the size, type of foundation, material for insulation and type of ventilation, you can start calculating.

For the construction of a bathhouse on a frame-panel basis, not a very large amount of building materials is required. Consider the variations of the materials used for the construction of each element of the structure.

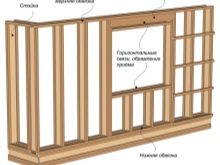

The material for the frame can be a wooden beam or a metal profile. Most often, summer residents prefer timber: it weighs little and is easy to assemble. The optimal section is considered to be 5 by 10 for supports and 10 by 10 for racks at the corners. Boards for ceiling sheathing are taken 34 cm thick and 13-15 cm wide.

It is worth choosing a material for sheathing the frame at the design stage. Because when assembling the frame, just enough space is left between the racks to fit one plate. This helps to avoid unnecessary gaps. Many people opt for oriented strand board.Working with it does not require special skills and construction equipment. While cement particle board can only be cut with a grinder.

For insulation, mineral wool, foam or fiberglass are suitable. The thickness of the insulation material should be the same as the thickness of the timber from which the frame is made.

In order to properly organize steam and waterproofing, it is undesirable to use roofing material. The fact is that when heated, it begins to emit a not very pleasant smell.

It is better to use it only for external waterproofing and when laying the foundation. And foil film will perfectly cope with the task of vapor barrier.

The interior decoration is most often made of wooden lining, but it can be decorated with completely different materials, it all depends on the owner's imagination.

You will also need metal sheets and bricks to equip the space around the stove as safely as possible.

The bulk of the estimate is often spent on materials for the foundation. Here the list depends on the specific type of foundation (for example, screw piles are not needed for the construction of a conventional strip foundation). But concrete is used for almost any foundation. Therefore, it is worth figuring out what it consists of and how to choose it correctly.

Cement

This material consists of clay, lime and special additives. Initially, it is in the form of sand, after dilution with water it acquires the consistency of a dough, after which it hardens and becomes hard like a stone. The poured concrete begins to harden in about 50 minutes, and it will take several days to completely dry. Dry concrete can lose its strength if stored or handled improperly. The material has strength classes that you should pay attention to when buying.

Sand

Sand is used as a filler when mixing concrete solutions. It can be river or career. The river is of high quality because there are few different impurities in it. The quarry often contains a lot of dust and clay. Sand must be sieved and washed before being added to the cement mortar.

Gravel

Small stones of natural origin are called gravel and are also used as aggregate when mixing concrete. Gravel is divided into river, sea and mountain.

Crushed stone

These are also small stones, but they are obtained by crushing larger ones. It can be small, medium and large. When choosing crushed stone, you need to pay attention to all its characteristics: strength, frost resistance and the level of radioactivity. Crushed stone used in the preparation of concrete must not contain clay or any inorganic admixtures.

Water is a very important component of a concrete solution. Drinking water is great for making concrete by hand or for compacting foundation layers. Industrial or natural water will also work if it is clean enough. The most important requirement for water is the absence of fat, oil, sugar and other artificial additives in the composition.

Deciduous varieties of wood are perfect for making the frame of the future bath. They are good for their low susceptibility to deformation and high degree of thermal insulation.

Of course, many people opt for a cheaper material (for example, pine timber), but it will only work for assembling the frame. It is undesirable to use it for finishing, because when heated, resin is released, which can be burned on.

Naturally, a large number of fasteners will be needed for construction. Their varieties and number are determined by the design of the future bath. It is better to take nails, screws, screws with a large margin, because it is very difficult to calculate how many of them will be needed during construction.

How to insulate?

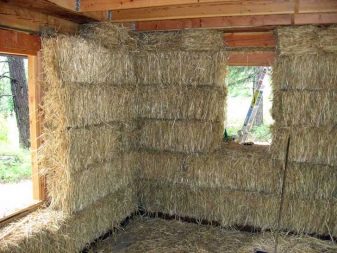

The most common material is roll insulation about 4-5 cm thick. Less commonly, mats or mineral wool are used.The insulation must be placed between the racks, and then the slats must be nailed to them. Polyethylene is well suited for thermal insulation. It is not advisable to use roofing material, since it emits an unpleasant odor when heated.

Not very common, but quite high-quality and environmentally friendly material for insulation - reed slabs. Their thickness is usually 15 centimeters, which is great for frame construction. There is nothing in the technology of its mounting to distinguish it from the installation of other insulation materials. There is one important nuance that should be taken into account when using reed slabs to insulate a bath. This is flammability. Therefore, it is worth paying special attention to anti-prine treatment before starting work.

A mixture of plaster and sawdust is also used by some builders as insulation. Such a mixture is very easy to prepare yourself by mixing dried sawdust with cement or gypsum in a ratio of 10 to 1. This insulation is perhaps the cheapest of the existing ones.

Polymer materials can also be used for insulation. The advantages are obvious: low cost, easy and quick installation, low weight and good thermal insulation of the material. Most importantly, it is completely insensitive to moisture. But there are also disadvantages: polymer materials burn quickly, are not intended for use in rooms with high temperatures and can emit unpleasant odors over time.

Basalt insulation was quite popular at one time. This is a kind of cotton wool made from mineral fibers and glue.

This material has many advantages.

- Basalt wool retains heat well.

- The ability to withstand temperatures up to 900 degrees.

- It can serve for more than twenty years, because over the years it does not deteriorate and does not lose its characteristics.

- Sound insulation in a bath, insulated with basalt wool, will increase several times.

- The material does not absorb moisture, which will allow it not to linger in the frame.

It would seem that here it is - the perfect insulation. But not everything is so simple. The main disadvantage of basalt wool was discovered only by 2014. Until that time, it was considered one of the most environmentally friendly materials. But it turned out that the adhesive that glues the fibers together releases formaldehyde vapors. Naturally, the popularity of this insulation has dropped sharply.

Expanded clay or other backfills can cope with the insulation of the floor of the coating; foam can be used for the ceiling.

You should take a very responsible approach to the stage of bath warming. Indeed, with high-quality work done at this stage, the heat will go away much more slowly, which means that there will be less costs for heating the bath.

Foundation

For frame buildings, a powerful foundation is not needed, thanks to the small mass of the frame itself, the simplest can be done. The most popular option is a columnar foundation. Supports here will be asbestos-cement pipes, poured with concrete.

Step-by-step instructions for equipping a columnar foundation.

- First you need to select and purchase asbestos-cement pipes. The optimal diameter of such pipes is 10 cm, and the length is 3-4 meters. Their number depends on the area of the future bath. The number of supports may vary, but they must be installed at all corners of the structure.

- The second step will be digging holes with a diameter of about 20 cm and about 1.5 meters deep. It will be easier if you have a gasoline drill, but you can also dig holes manually, it just takes much more time.

- Next, you need to cut the pipes in half and place them in the resulting wells. The place around the pipes is covered with sand and compacted very carefully.

- Then you need to mix the concrete solution. This can be done according to the standard proportions scheme - 1 unit of cement itself, 2 units of sand, 4 units of crushed stone and water.

- At the last stage, the pipes are filled with concrete. After the foundation has completely dried, you can start building the rest of the bath.

Wooden foundation

For smaller buildings measuring 3 x 4, 3 x 5, 4 x 5 or 3 x 6 meters, a simple wooden foundation can be fitted. This is also a good option for moving clay soils. Do not forget that the roof and walls of small buildings should be light. Otherwise, you will need to think about a solid foundation.

Pile-screw foundation

For a large frame structure, this option is best suited.

The construction technology is simple:

- marking is made for the location of the piles;

- holes are drilled in the ground for piles, while the depth is determined accordingly with the type of soil and the level of occurrence of groundwater;

- piles are screwed into the holes;

- the last step is to assemble the harness.

Strip foundation

For heaving soils, a strip foundation is ideal.

You can also equip it with your own hands, following the instructions.

- On the site for the bath, you need to dig a trench about 45 cm wide and about half a meter deep.

- This trench is filled with sand to the very top. Like a cake, the foundation is laid in layers and each layer of sand needs to be tamped, adding water will help.

- Next, a formwork is placed with dimensions of approximately 45 by 30 cm. The base of the formwork can be reinforced with metal pipes and rods.

- Then concrete can be poured.

- After the concrete has completely dried, the foundation is covered with roofing material. This will provide the necessary waterproofing of the frame structure.

Walls and floor

To build strong walls of a frame bath, it is enough to follow some rules:

- It is necessary to dry the lumber well. It is not recommended to build from birch, as it rots quickly. Aspen, linden or larch, which have good thermal insulation properties, are better suited.

- Boards of all rooms, with the exception of the steam room and shower, are treated with an antiseptic from the inside. Outside, varnish is usually applied. The lower harness is made of beams fastened with nails.

- It is necessary to brick the corner posts in concrete.

- When lining with clapboard, it should be overlapped to avoid the formation of gaps between the sheets. Also, this method protects against moisture penetration.

It is most convenient to assemble the frame in a free area in the yard. The distance between the uprights depends on the type of cladding material used. So that the sheets organize a solid wall and they do not have to be adjusted, you can take a step of 60 cm. The same size is suitable for installing insulation, which is placed between the racks.

In those places where ventilation holes will be made, the gaps can be increased by another 30-35 cm. The distance between the vertical supports is filled with thermal insulation.

The outer cladding is often made of wooden lining laid horizontally.

Floor arrangement

The design and flooring can be different depending on what kind of bath room it is being made for. Where water will constantly flow, it is better to make a pouring floor. It is assembled from ordinary boards not close to each other, but with small gaps so that water flows into the ground. Insulation is not required for such a floor.

The work of laying the floor begins with laying the logs. Support posts will be required if the distance between the support points is more than 3 meters. In places where the lags touch the base, roofing material is laid in several layers. The boards are mounted on top of the joists. A spilled floor is most often not fixed so that it can be lifted and properly dried.

In the rest of the premises (steam room, changing room and rest room), the floors are also installed quite simply. The bars are attached to the logs, and boards for the subfloor are placed on top. Roofing material and insulation about 10 cm thick are laid on them. When installing boards for the final floor, you must not forget about vapor barrier equipment using glassine.

A completely different technology is needed for the shower floor. You can even make a separate foundation for this room. Lags for such a floor are asbestos-cement pipes.On top of them, an edged board with a thickness of about 5 cm is laid. Small gaps of 5-6 mm must be left between the boards. At the end of all the stage, the floor is pressed with plinths.

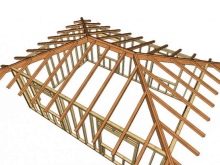

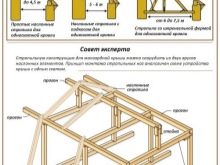

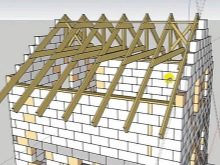

Roof

To summarize, the roof structure consists of two main elements: the rafter system and the flooring itself with lathing. It can also include an attic floor, but often flat roofs are made without it. The roof for a bath can be single-pitched or gable. Four-slope structures are much less common. The scheme of their construction is quite simple and even a novice builder can handle it.

A roof with one slope is built when the bath is attached to the living space or, if necessary, to save money. Its advantages are the absence of requirements for the height of the roof, low cost and ease of construction.

A gable roof is often made in log baths. The owner chooses the height and slope, taking into account the weather conditions in the region and the existence of plans for the further use of the roof space.

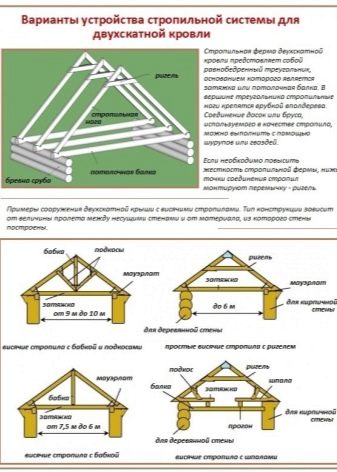

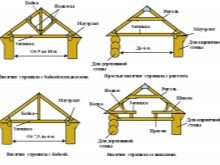

The types of rafter systems are shown in the diagram.

The angle of inclination of the roof can be determined independently, the larger it is, the easier the precipitation will slide off the roof. A too steep slope should not be done in areas with strong gusty winds. In the snowy regions of the north, an angle of 45 degrees will be optimal, and in places with abundant winter precipitation, it is better to equip a flat roof. It must be remembered that the smaller the roof angle, the less material will be needed and the cost, of course, will be lower.

Support

The beams and the base for the rafters, which is located along the perimeter of the walls (mauerlat), serve as a support. Beams can extend beyond the walls by no more than half a meter, otherwise additional supports will be required. The pitched roof system is supported by walls at different levels, and the trusses are fastened with rafter bars and purlins.

Methods for installing rafters

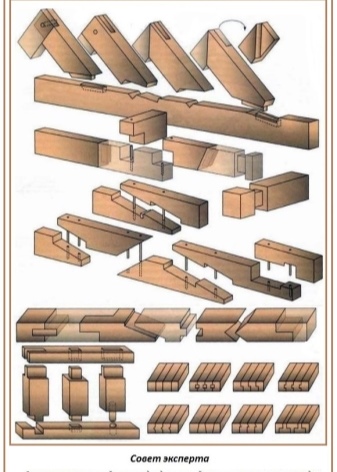

Rafters are the basis of the future roof. It is easiest to build from ready-made elements, connecting them with self-tapping screws or screws. Notches should be made exclusively at the points of support, and which ones and where are shown in the diagram.

Rafters are hanging and layered. Let's take a closer look at each of the varieties.

Hanging rafters

Such rafters abut each other at the highest point, forming a perceptible horizontal pressure. To reduce it, you need to build a lower belt, which in this design can be called the base of the "triangle".

It is worth paying special attention to the connections in such a rafter system, they must be as reliable and rigid as possible in order to cope with significant loads.

Sliding rafters

This type is more commonly used for pitched roofs. There is no need for puffs to lay the rafters. They are installed simply along the slope and rest on the Mauerlat, which, in turn, rests on the load-bearing walls. Options for the construction of a system with layered rafters are shown in the diagram:

Gable roof rafters

The basis of this roof is the rafters of the same size, installed alternately. The roof, insulation, hydro and vapor barrier are later laid on this base. Depending on the design features, the "isosceles triangle" is supplemented with additional reinforcement elements.

For convenience and safety, you can assemble the rafter system on the ground. True, then it will have to be lifted up, which will require a whole team of workers or special construction equipment.

Professional builders recommend to start with a template that will be exactly the same in shape as all subsequent truss trusses. To do this, you need to connect two trusses at the top with a nail. Then the opposite ends are placed at the point of the future support and fixed. It is important throughout the entire work to control that the installation of the rafters is clearly vertical.This can be done using plumb lines.

Installation begins with the installation of frontal trusses, between which you need to pull the cord (in the future, it will serve as a guide). The standard distance between the rafters is 1.2 meters, but the value can vary both up and down, depending on the characteristics of each individual roof.

Shed roof rafters

The basis for the insulation is laid out for such roofs with an optimal pitch of 0.5 meters. If the distance between the supports is less than 5 meters, additional stands can be omitted.

Beyond the perimeter of the building, the rafters are usually taken out by 40-45 cm, which will help to equip the cornices. For the material of the lathing, a beam or board is suitable. The step between its elements is determined in accordance with the type of roof. For a soft roof, a plank sheathing with intervals of 1-2 cm is suitable.For a sheet roof, it is made of a bar with a distance between the elements from 20 to 45 cm.

Installation technology involves starting work from the ridge and gradually moving to the cornices. For fixing, ordinary screws or self-tapping screws are used.

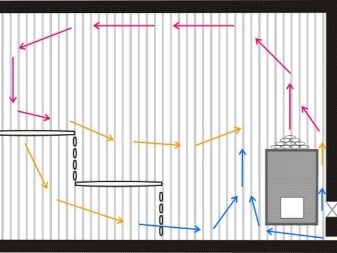

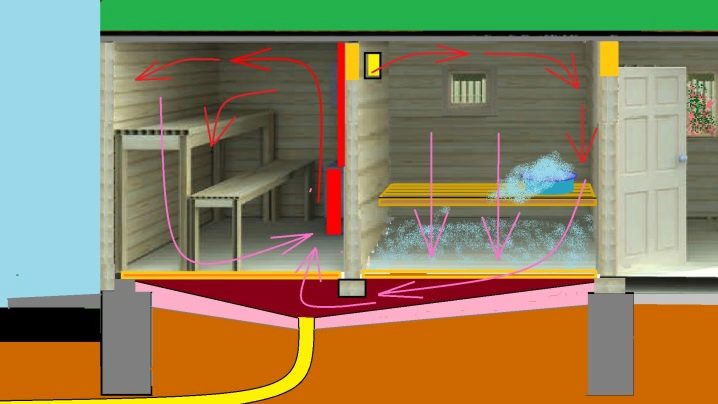

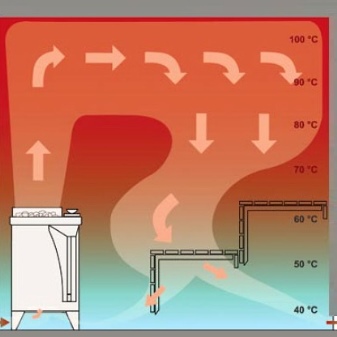

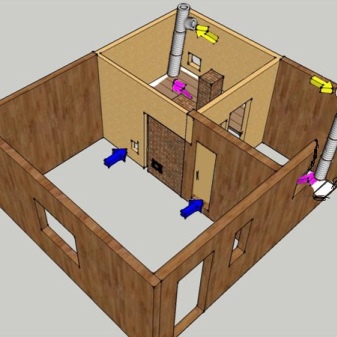

Ventilation

Ventilation system equipment is one of the most important stages in the construction of a frame bath. Its quality depends not only on the comfortable conduct of bath procedures, but also on the safety of people inside.

For kindling, coal or wood is used. In order not to be poisoned by carbon monoxide and to prevent the penetration of combustion products inside, high-quality ventilation is necessary. It will also help to cope with the formation of fungus and condensation.

At certain intervals, air should not be released from the steam room, which means that the ventilation must be tightly closed. It is desirable to organize a system with the ability to manually control the movement of air in the bath.

It is important to think over the system in advance, even at the design stage. Introducing ventilation into the finished building will be very problematic.

Separate ventilation systems are meant for different types of buildings. This also applies to frame baths.

It is very important that there is a place for excess moisture and heat to go. For frame structures, professionals advise installing adjacent ventilation. She will be able to get rid of excess steam, and bring fresh air instead.

You will need two holes - through one air will enter the room, through the other it will exit. Pipes are installed in them, which can be supplemented by installing fans. Such a system will work in all weather conditions.

To get good ventilation, you need to place these holes as correctly as possible. Then the air will be able, roughly speaking, to enter where it needs to and exit where it needs to.

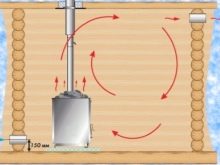

There are several standard hole patterns. The first thing to consider is the location of the firebox in the bath. If it is inside the steam room, it will need to work according to one scheme, if outside it - according to another.

The supply pipe should be located fairly close to the firebox, but below the level of the chimney. Chimneys are often placed in the opposite wall just below the ceiling.

Sometimes in frame baths, two outlets are made (not far from each other, but at different heights) and one inlet. This helps to control the movement of air masses in the bath. There is a clear rule of thumb: the higher the exhaust port, the stronger the draft. That is, it is not necessary to make an outlet pipe both in the middle of the wall and near the inlet. Otherwise, the ventilation will lose its functionality.

Gate valves are of particular importance. This will allow you to regulate the flow of air into the room. This is very important if it is windy outside. It is recommended to make not only valves for closing pipes, but also to install a fan inside.

This will make it possible to ventilate the bath well even in the complete absence of wind outside.

When using a steam room, you need to open the valves every three hours and renew the air. Otherwise, being in the bath can become unsafe.

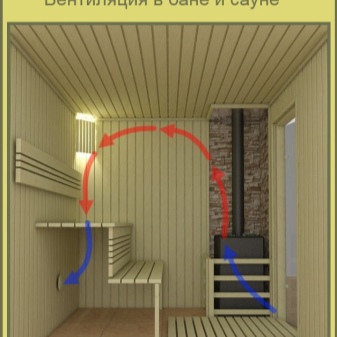

Ventilation for a sauna with a stove in an adjacent room with a steam room

This type of stove placement is the most common. Its significant advantage is the absence of garbage in the steam room and heat preservation (since you do not have to open the door often).

Adjacent ventilation is suitable, and for hot steam to enter the steam room, you need to organize a kind of tunnel under the floor. Its role can be played by an ordinary pipe. A grate should be installed at both ends of this pipe, and a gate valve is needed at the outlet to regulate the flow of air inside.

The opposite wall (or diagonal wall) will be the best place for the hood equipment. Its role can be played by a box with dimensions of about 25 by 30 cm.

It is important to remember that all vents must be the same size. Otherwise, the system simply will not be able to function normally: for example, hot air will come out faster than cold air has time to enter and heat up.

Ventilation system for a sauna with a stove in the steam room

The option of placing the firebox directly in the steam room is not popular. After all, it takes up a lot of space, and garbage constantly remains from firewood and coal on the floor. But for such a room, there are separate rules for arranging ventilation. Oddly enough, everything is much simpler here.

Some sauna owners do not even spend time organizing an additional ventilation system, but simply let off steam through the open door. In this case, fresh air enters the steam room with the help of a blower, which is in every stove. If the stove does not have a full-fledged pipe, you will have to equip ventilation according to all the rules - with inlet and outlet pipes.

It is better to place a stove without a pipe on a kind of podium, so that it is more convenient to bring the pipe to it from the street. It will also allow air to circulate quietly in the building.

Reviews

If you have doubts about the construction of a country bath on a frame system, you can ask about the reviews of the owners of such buildings on Internet forums. Here, of course, opinions differ: some write that they are unhappy with the bath because of the rapidly appearing fungus on the walls. This is often due to the fact that the room cools down too quickly.

This can be dealt with with high quality insulation. After all, low-grade foam or mineral wool will not be able to fully perform the necessary functions. Also, cheap styrofoam can catch fire suddenly.

Even in the reviews, they often write about the significant shrinkage of the bath. Some examples indicated a shrinkage of about 10 cm in just 1.5 years. This, accordingly, leads to deformation of the external and internal finishes.

Probably, it will not be possible to completely prevent the shrinkage of the bath, but it can be minimized by using lumber after chamber drying.

Those owners who did not save on insulation and other building materials note a great advantage - compared to a log structure, the frame version is much less laborious and complex.

If we summarize the most popular reviews, then the main problems of such baths can be called the high costs of insulation, shrinkage and insufficient fire resistance. Despite this, frame baths are gaining more and more popularity due to an extensive list of benefits.

Tips & Tricks

- The pillars that will be the basis of the walls of the bath should be placed in places of greatest load: at the corners and load-bearing walls, under the stove.

- The thicker the insulation material, the better the building will be insulated. The width of the frame boards is also of great importance. A board with a width of at least 15 cm is recommended.

- Before proceeding to the construction of the frame itself, it is worth making sure that the foundation is completely dry. Proper drying should be gradual. To do this, cover the entire structure with polyethylene for about 3 days, then remove it and wait a couple more days.

- When equipping the base of the floor, it is imperative to leave room for the stove foundation.

- Modern building materials are made practically non-combustible, but the abundance of wood makes one think about fire safety techniques. The wall, to which the stove is adjacent, is best laid out of bricks. It will not be superfluous to lay bricks on the site around the stove, and the floor must be covered with a metal sheet so that the coals (sparks) that have fallen out of the rough do not burn it.

- If the stove in the bath is made of metal, then you will need to first strengthen the frame at the place of its installation. For a brick oven, you need to equip a separate foundation. You also need to provide a room where there will be a container with water if no water is supplied to the bath.

- It is clear that if you need to save space, you can design bath rooms of any size. But the steam room has a minimum size limit - 2.5 by 2.5 meters. If it is smaller, it will create a lot of inconvenience when using it.

- After the sub-floor has been laid, it should be treated with a waterproofing solution. This will extend its life and protect it from moisture penetration into small cracks in concrete. The latter, in turn, can harm not only the floor material, but also the insulation.

- To avoid dampness, it is necessary to lay a vapor barrier in front of the insulation layer, which can collect condensate.

- When choosing a heater, special attention should be paid to its high temperature characteristics. Indeed, for a bath, this is a determining factor. It is worth remembering that many materials perfectly perform the function of warming, but under the influence of high temperatures, they begin to release various substances that can adversely affect health.

- Not being a professional builder and not having much experience, it is worth spending a lot of time drawing up a project. In it, you need to describe in detail all the stages of work, the materials required and estimate how many people may be required to complete the work. After all, it will be very unpleasant in the middle of construction to understand that you do not have the opportunity to continue it due to the omission of some important stage in drawing up a plan.

- If there is a strong need to save material resources, straw, sawdust and other available materials can be used for insulation. But their use is a priori unsafe, because they have a very high flammability. You need to find the best option so as not to spend too much, but also not to risk your life every time you heat the bath.

Beautiful examples

The restroom is decorated in a traditional style: wooden benches, a samovar and calm warm lighting perfectly contribute to relaxation after taking a bath.

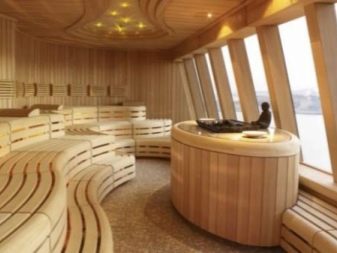

In such an original way, you can lay out a wooden lining in a steam room. In this example, the lamps are very well disguised: they themselves are not visible, and the light is beautifully scattered through the peculiar wooden elements.

A variant of a frame bath with a small veranda. It looks quite simple and at the same time, all the basic rules of decor are observed.

This rest room is completely finished with wood, which does not prevent the mirror and upholstered furniture from being quite harmoniously fit. In order to match the color of the main material, the lamps for this design were chosen in yellow.

A striking example of eco-style design: all elements are made of natural materials, canvas with ethnic patterns is great for curtains and tablecloths. Furniture frames are also made of wood that is close to natural form.

In this case, the design turned out to be very brutal. Animal skins, iron elements and a massive wooden billiard table create a real "men's den" in which you can spend hours with friends.

Minimalism is rarely used to decorate baths, but this example can be called a standard. The contrast of wall colors looks great in combination with a composition of paintings and stylish furniture.

This decoration was clearly done by real craftsmen. There are carved furniture, mosaics of small tiles, and fancy wooden compositions on the wall. All this creates a unique composition and disposes to rest.

And here is an interesting design in a nautical style. A homemade table in the form of a coil with a rope is an original solution that can be repeated by every lover of unusual furniture.

This design option looks very rich and expensive. Hardly any private owner designed it himself, but he clearly has a sense of style. Obviously, this decoration took a lot of time, the brickwork alone on the back wall takes a lot of effort and time. Equipping a fireplace is also a very laborious process, but the result is amazing.

In this design, they managed to competently combine dark and light wood, a forged lamp and fancifully romantic curtains on the windows. This decor can hardly be attributed to any particular style, but it all looks very aesthetically original.

A chic decor element is a horn chandelier. Of course, to simulate horns, most likely, an ordinary tree was used, but it is so beautifully crafted that associations come naturally. Such a chandelier, with a not very powerful light bulb, will be able to cast fancy shadows on the walls, complementing the atmosphere.

Quite simple, but interesting design of the rest room with ceramic tile floor, artificial barbecue and stained-glass window on the window. It is also worth paying attention to the method of lighting equipment: the lamps are hidden in the ceiling support. So they are not a special decoration of this interior, but they also do not distract the eye from its main elements.

High-quality wicker furniture is an excellent solution for decorating a rest room. It goes well with light-colored timber. But it is worth noting that the owners of the baths often do not paint the walls from the inside, but leave them in their original form.

The attraction of any two-story building is the staircase. This example shows a chic curved structure with wrought iron railings. Such projects are most often made to order and require large financial investments, but such an element can turn a bathhouse from simply beautiful into a gorgeous one.

It will take a lot of time and effort to design such a steam room, but the result looks incredibly large and majestic. You will want to bring guests to such a bath all the time, because the dimensions allow you to accommodate quite a lot of people.

Homemade stained glass is an ideal design solution for decorating a window in a steam room. It looks much more impressive than a simple curtain and at the same time obscures the view from the outside of the building. The technique for making such a stained-glass window with your own hands is given above in the article.

Here we see an original device in the form of a shower cabin with a wooden base. You can, of course, work hard and make something similar yourself (or order from a master), but you can again achieve a similar effect using a film with a pattern that imitates a woody pattern. True, such a film will not last long inside the cab.

How to equip a frame bath, see the video below.

The comment was sent successfully.