Bath from a log: pros and cons, stages of construction

A log bath has both pros and cons. The process of its construction has a certain specificity: there are characteristic stages of construction, which are not so obvious at first glance. In order for a log bath to be built correctly, the builder needs to familiarize himself with some theoretical information.

Peculiarities

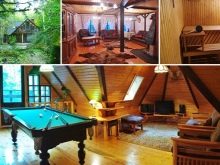

A log bathhouse is a traditionally Russian building. Such baths were built in Ancient Russia, but since then the technology has been somewhat changed and improved. In particular, this is due to the fact that the technology for making logs has changed a lot. The requirements for bath buildings have also changed. So, now it is necessary that the bath be equipped not only with a dressing room and a steam room, but also with a shower, a bathroom, a recreation room, and a billiard room. The size of the bath and, accordingly, the amount of material depends on how many rooms will be equipped.

Wooden baths differ from their brick counterparts in a number of advantages.

- Wood has a wonderful effect on human health. The healing steam in such steam rooms improves mood and improves overall well-being. Depending on which wood is chosen, the effects produced differ. For example, if you choose to build coniferous logs (spruce, pine), then you can be sure that after visiting the bath, your mood will increase, insomnia will disappear. In addition, the evaporation of the resin produced by these rocks has the ability to kill viruses in the human body.

- The timber is an environmentally friendly material, so that even in the process of destroying the bath, the environment will not be harmed. Recycling logs is also very easy: you just need to unload them somewhere in the forest. This will turn your trash into useful fertilizer.

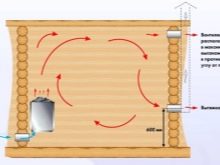

- Ventilation in wooden buildings at a height. This is due to the fact that the timber by nature has excellent ventilation properties, so that there will be no problems with stagnant humid air. Thanks to this feature, during the bath procedures, a microclimate is formed that is most suitable and comfortable for vaping, in principle, and as a result, the best results are achieved.

- Wooden baths keep warm well, do not cool down quickly. Wood has a low thermal conductivity, which cannot be said about brick. Low thermal conductivity gives another advantage: in winter, a log-house bath will warm up several times faster than a brick one.

- Thanks to natural ventilation and low thermal conductivity, it will not be necessary to spend additional financial resources on equipping a wooden bath with ventilation, and it is also not necessary to additionally insulate it. As a result, this will save much more money than was spent on the purchase of logs.

- The surface of the wood is attractive in itself, so no additional cladding or interior decoration of the bath is required. If a profiled beam was chosen for the construction, then the building will look neat and tidy, it will not "sit down" or warp. In addition, the soundproofing qualities of the tree are at a height.

- A wooden bathhouse on the site is evidence of the high status of the owner. It can even be called a status thing. In addition to the fact that it is convenient and beautiful, the sauna from a bar gives you the opportunity to get together with a company or family and have a good time with sincere conversations in between procedures in the steam room.

Materials (edit)

When deciding to build a log bath, several factors must be taken into account, the first of which is the difference in materials.

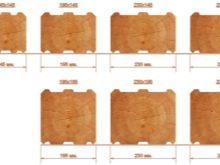

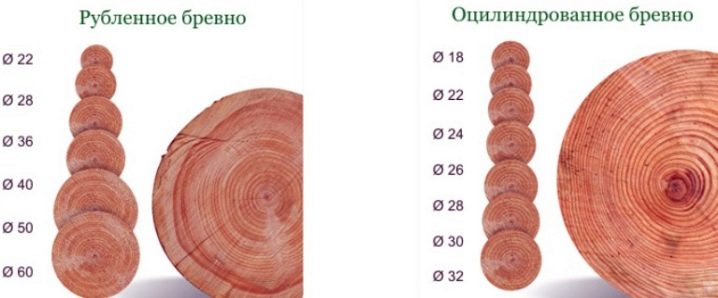

Chopped or planed logs (they are also called debarked) are an ordinary oval-shaped log house, all processing work was carried out manually. The top layer of wood, called sapwood, is carefully removed. As a result, logs of different sizes are obtained, a little knotty and rough to the touch. Due to the fact that the tree is not polished and, roughly speaking, remains in its original form, it retains the ability to resist all kinds of negative influences that can be exerted on it not only from the inside of the bath, but also by the external environment. Since the logs have different diameters, it is quite difficult to achieve good thermal insulation: it is necessary to have experience with this material. In addition, chopped logs are cheaper.

Rounded or calibrated log has a high cost and a completely different appearance. The logs are processed here on a special machine, which makes them all equally round, even and beautiful. The result is a smooth surface without a single roughness. However, along with the original appearance, the tree loses a good half of all its qualities with such processing. The forest becomes more sensitive to external influences as it loses most of its stability. However, the craftsmen found a solution to this problem: they repeatedly process the wood with various impregnations and antiseptics, and as a result, the rounded wood becomes more stable.

Solid block buildings are popular, but you need to know which array to choose.

The following breeds are optimal:

- spruce;

- Pine;

- larch;

- oak;

- birch and others.

All of these options are dense and solid enough to withstand constant exposure to hot temperatures and steam. It is best to buy timber brought from the northern regions. Wood from the Pskov region is in the greatest respect and demand. You also need to pay attention to the time of purchase: it is best if the wood was harvested in winter. Try not to select logs that are too thick, as they will crack faster than others. It is worth giving preference to young trees of medium diameter.

After purchasing timber, you need to carefully consider the preparation for subsequent construction. It is necessary to let the log house “lie down” for at least a month. Logs are stacked. It is necessary to leave a ventilation gap of 5 cm between them so that the material can "breathe". Only after the blockhouse is "laid back", you can start construction.

The choice and preparation of material is an important step towards building a bath. You should not try to save money by choosing low quality wood. The walls of the bathhouse may crack and the thermal insulation properties may be below average. In order not to risk it, buy high-quality timber, cut down in winter and supplied from the northern regions.

Project

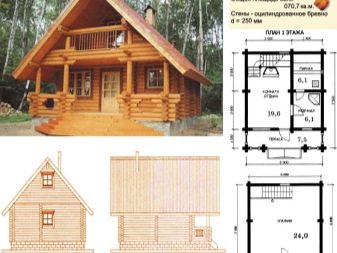

Going directly to the planning of the bath building itself, it is worth deciding on its specific appearance and layout. There are two ways: either you can choose a ready-made project, or create your own individual one that meets all the requirements and wishes of future owners. The first way is simpler. Examples of projects with their brief description will be offered below.

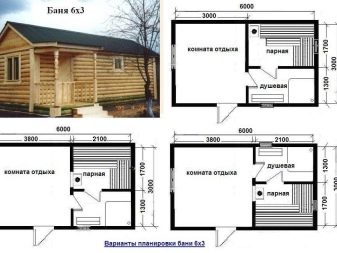

If you are planning to build a small bathhouse, for example, 6x3 m in size, then it is worth taking a closer look at the minimalistic options with a small number of rooms. In this project, only the essentials have been left: a shower, a steam room and a spacious dressing room. This is enough for a comfortable sauna rest.

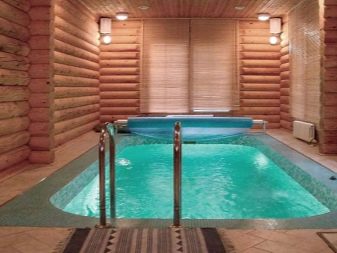

Such a bath is more like a whole house, especially given its impressive dimensions. Here, the rest room can no longer be called a dressing room due to its large area and high functionality.If desired, the recreation room could be supplemented with a TV or converted into an indoor pool.

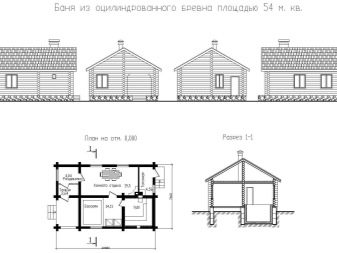

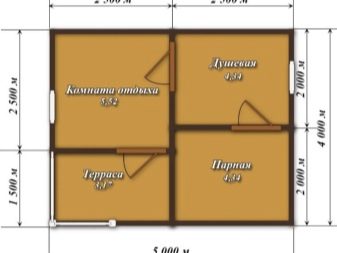

Small wooden sauna 6x6 m equipped with everything you need, including a bathroom. Even a small building can have sufficient functionality. The only thing that is inconvenient in this project is that the stove used here is not equipped with a remote firebox.

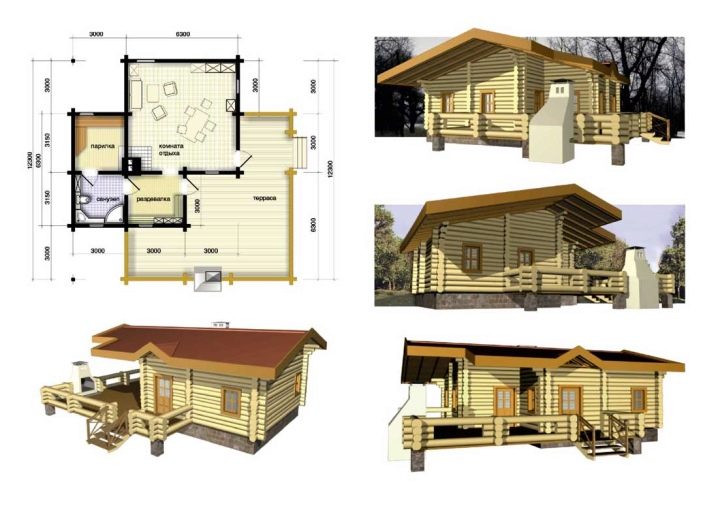

The bathhouse can become a full-fledged resting place, especially if we supplement it with several functional areas: equip a barbecue on the terrace, equip a recreation room with a TV, or come up with something else. The limitation is imposed only by the design area.

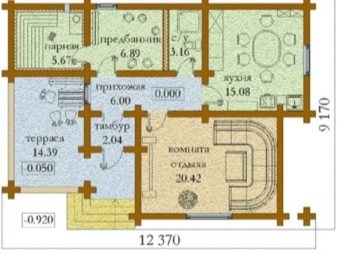

A really large sauna, equipped with a special room for the pool. As can be understood from the plan, this building is two-story, but it is not necessary to equip the second floor or the attic: the building is good anyway.

Here the bathhouse is equipped with a veranda. In one building, two recreation areas are combined at once: on the one hand, the terrace can be used simply for tea drinking, on the other - to relax on it after the sauna events.

Another small project that involves entering the recreation room through the vestibule. Among others, there is also a technical room that helps to control the functioning of all systems. The electric oven is controlled from here.

A good example of what a project shouldn't be. Please note that there is no access to the rest of the premises, except for the vestibule. Be extremely careful when drawing up project plans and do not make such elementary mistakes.

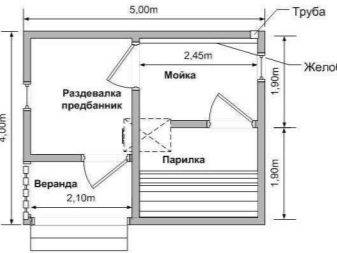

Miniature baths 4x5 m may be enough for a good rest. A large company cannot accommodate here, but if the building is being built for a small family, a steam room of such dimensions will be more than enough.

In which case, it will even be possible to live in such a building in the summer. In the kitchen, you will need to make a hood, because if the smells from it reach the steam room (which is unlikely), then the tree will absorb all unnecessary aromas, and you will not be able to get rid of them.

As for individual sketches, they can be drawn up independently or commissioned by a professional. The main thing is that your bath is of the right size and contains all the rooms, in your opinion, necessary. Despite the fact that one-story buildings are more popular than two-story buildings, in some cases two floors can save the area of the site, while creating additional space in the bath building. Please note that the steam room is always located on the floor, since a reinforced foundation is required for the stove.

Foundation

In order to make a foundation, no special knowledge and experience is required. All you need is to arm yourself with materials and tools and be ready to spend a sufficient amount of time on construction.

You will need the following materials and tools:

- fittings;

- lumber;

- nails;

- a pair of rolls of roofing material for waterproofing;

- plastic air vents;

- wooden stakes;

- rope;

- hammer;

- shovel;

- level.

Pay attention to the condition of the soil. If it is heaving, then it will be necessary to additionally strengthen the foundation with reinforced belts.

Now you can start building the foundation from scratch. Below is a list of steps to be followed in stages.

- Delineate the area for building a bath with stakes and a rope. Install the stakes at the supposed corners of the future bath, and pull the rope between them.

Keep in mind that the foundation should be 45 cm high. This is quite enough for a log bath. If you make the foundation lower, then it may not be possible to arrange all communications, and a higher foundation is an extra waste of money.

- The shovel should be well sharpened before you start digging the trench. Use a grinder for sharpening.

- Dig trenches 50 cm deep, strictly observing the boundaries marked in the first step.

- The walls of the trench should not crumble, for this the shovel was sharpened. If you are building a bathhouse on a site with loose soil and there is no way to fix the situation, then protect the walls from shattering with wooden panels.

- In the corner, dig a section for the future boiler. Its size depends on the dimensions of the boiler you have chosen.

- Check how high-quality lumber was delivered to you. It is extremely important that it is truly of high quality: then the base will not crack or fall apart. The lumber should not have any knots or breaks.

- Place the box along the edges of the trench without submerging it. The lumber box should be slightly larger than the width of the trench. Every meter on the walls of the box made of longitudinal boards, one transverse bar must be installed. Fasten the wooden "walls" on the sides with self-tapping screws.

- Reinforce the trench by installing metal rods in it. They should be 10 cm distant from the wall and protrude 1.5 cm up.

- Check the width of the box in several places. The distance between the walls must be the same everywhere, otherwise the foundation will not be perfectly flat. Cover the inner walls made of wood with roofing material.

- Install the air vents by placing them across the borders of the box above the trench. Thanks to them, the air will constantly and freely circulate under the bath.

- Fill the foundation. You can use a special machine for this, or you can simply throw concrete into the trench and box with a shovel. In the process of laying the mortar, be sure to level the places in which the concrete has already "grabbed" and went bumps. This is done in order to completely level the foundation.

- Leave the foundation to dry for 30 days. If there is a concern that precipitation will fall, then cover the structure with polyethylene, otherwise just leave it to dry in the open air.

How to build?

After the foundation has been erected and dried, it is time to build the bathhouse itself. Note that it will take some time after the logs are cut down. Only then will they be as well suited for construction as possible.

To build a bathhouse with your own hands and at the same time do everything right, use the following instructions.

- One row of logs in a building erected from a log house is called a crown. The first crown should be as strong and evenly laid as possible, since it bears the rest of the load. Therefore, a blockhouse is chosen from hardwood: oak or larch. Only such rocks have a sufficient margin of safety to withstand the weight of the entire structure and heat and moisture loads, while not cracking. For the first crown, it is permissible to use large diameter logs.

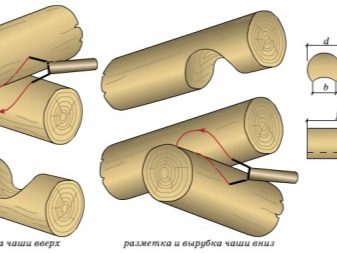

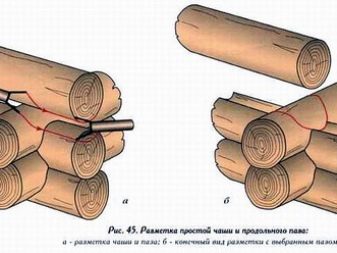

- The first crown is laid on a foundation equipped with waterproofing. It is extremely important to pay special attention to the treatment of logs with all kinds of antiseptics and moisture-repellent impregnations. The lower part must be cut to ensure maximum adherence of the log house to the foundation. When laying, you can use the method "in a bowl" or in a paw, as well as "in a flash". The marking process and manual felling technology are shown in the following pictures. The depth of the groove depends on the ambient temperature in winter: the colder it is in the region in which you live, the deeper the groove must be.

- When laying, keep in mind which side the log is located on. So, its north side should be located outside, and the south - inside. The side is determined by the growth rings on the cut: they are thinner on the north side. This feature is due to the fact that the tree on the north side is more resistant to negative influences and less prone to warping, so the likelihood that the log will crack or rot is minimized. A bathhouse built in this way will be able to stand many times longer - from 50 years.

- Since the timber cannot be of the same thickness on both sides, it is placed with the thinner side in one direction or the other. This helps keep the top edge horizontal. After the walls are laid out, it is necessary to dig them in - to plug up all the cracks and gaps. Caulking can only be done with some suitable materials: hemp fiber, dried moss, linen tow, felt. These materials will perfectly tolerate the shrinkage process, while they will not lose their properties over time. The bath is caulked in a circle, "passing" gradually along all the seams from top to bottom. If you carry out the caulking first on one wall, then on the other, and so on, then the bath can be "led".

- The upper crown, also called the mauerlat, must be chosen as carefully as the first. Mauerlat will continue to hold the roof, ceiling and, in general, the entire rafter system.

Roof

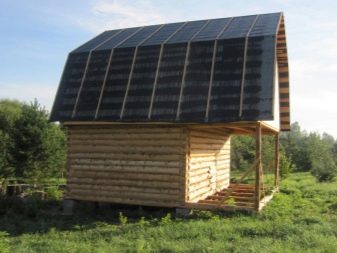

The roof is being built over the log bath in the same year. It can be both temporary and permanent, but it is extremely important to build it within this time frame. It is best to choose a roof of a simple structure, for example, a gable. Superfluous delights will be useless. A small attic must be left under the roof, but it is important to ensure that it is well ventilated.

Depending on the snow load, the distance is determined, on which the rafters are located from each other. Usually the step is 1-, 15 m. If you plan to equip the attic for a room or you just want to insulate it, then select the distance between the rafters depending on how wide the insulation slabs will be.

To install the rafters, it is necessary to cut from into the upper crown - the Mauerlat. It turns out that the upper crown, as it were, serves as a support for the rafters.

The rafters are connected to each other at the top. Then you can start forming the roof itself. First you need to make a crate for a gable roof. An example of how she looks is shown in the photo below.

Any waterproofing material, for example, roofing felt, is placed on the crate. It will protect the tree that has not yet had time to properly sit down from getting wet.

Only after the construction of the waterproofing layer can the topcoat be laid. It depends on the project and is usually chosen for aesthetic reasons. Ondulin, slate, metal roofing, corrugated board and others can be cited as examples.

Since the main functions of the roof are protective, then after its equipment, you can safely proceed to finishing work, including making floors.

Although gable roofs are usually chosen, there are cases where a pitched roof structure is more acceptable.

The choice of this or that option depends on a number of factors.

- The location of the bath. The wooden structure can be either freestanding or attached. In the second case, the option with a pitched roof is more relevant.

- Finance. The construction of a gable roof is much cheaper than a gable roof, and many choose this option in order to save money, even though it does not look so attractive outwardly.

- The presence of an attic. So, if its equipment is planned, then it is best to make a gable roof, otherwise you can successfully do with a gable structure.

Gable roofs with a high ridge look most attractive on log baths. Having insulated such a roof, you can make an additional room: a recreation area, a billiard room, a room for storing towels and other bath accessories. If you do not insulate the space, it can also be used by adapting it for storing brooms, for example. Shed roofs are usually made almost flat, practically without a slope, which fundamentally affects the fact that no room can be equipped under them.

Insulation

A log bath is insulated both from the inside and outside.In theory, a variety of synthetic materials can be used for insulation, most of all resembling foam. However, it should be borne in mind that during the construction of insulation, the lion's share of the useful qualities of bath procedures is lost. This is due to the fact that the vapor barrier does not allow the walls to "breathe", so that the microclimate created in the steam room cannot be called useful.

Among the materials for insulation there are those that should not be used. One of them is waterproof foam, which contributes to the creation of a greenhouse effect in the steam room. This also includes synthetic polystyrene: in the process of heating, it evaporates highly toxic substances that are dangerous to humans. Mineral wool is also a bad option as it cannot withstand high humidity. Materials on a plastic basis, when heated over 60 degrees, quickly collapse. It can be concluded that synthetic compounds are not suitable for insulating a log bath.

It is necessary to use only natural insulation.

- Tow. This material is used for insulation quite often. This is due to its excellent thermal insulation properties, low price, as well as a convenient form of sale in rolls. It is very easy to lay tow between logs. The insulation procedure with this material takes a little time, and the result exceeds all expectations.

- Ecowool. The advantage of the material is that it can be used to regulate the humidity level in the steam room. This environmentally friendly material is able to absorb excess moisture when there is too much of it, and give it away when there is not enough. Thus, the most comfortable microclimate is guaranteed. Among other things, ecowool perfectly insulates, "locking" the heat in the room.

- Jute. Another name for jute is felt or linen. The material consists of a mixture of linen and jute fibers. It has increased strength characteristics, more dense, which makes it an excellent choice for insulating a log bath. Felt does not rot, insects grow in it, and the material is also heat-resistant.

- Moss. Since moss is difficult to work with, it is rarely chosen. Only a professional is able to carry out work on insulation with moss correctly and quickly. Nevertheless, moss perfectly protects against heat loss, it is completely natural, environmentally friendly, so some people still prefer it.

The bath must be insulated. This is done in order to keep heat loss to a minimum, otherwise you will have to constantly turn on the oven at full power. It will quickly fail and you will have to make repairs. It is much more correct and cheaper to immediately properly insulate a wooden bath, thereby reducing all possible negative consequences.

Finishing

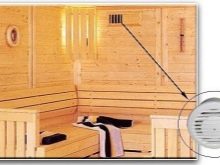

By and large, finishing the bath from logs is not required. This is due to the fact that it already looks aesthetically attractive and neat. Nevertheless, many ordinary log walls seem boring and they think about how to update the interior design.

Any work on the design of the bath should be postponed until the moment when the structure completely shrinks. The interior decoration of the steam room, if it is planned, must be carried out only with the help of environmentally friendly and natural materials. Also, do not use metal parts, as they will become scalding hot when heated. This will increase the risk of injury. This partially applies to fasteners, but if it is not possible to use wooden ones, then galvanized metal must be buried.

For interior decoration of a bath from a bar, a lining is perfect. It needs to be subjected to additional processing, well impregnated with antiseptic compounds. As for wood, linden and larch are optimal for a steam room.They do not heat up, so even if the temperature is very high in the steam room, you will not get burned. Coniferous lining cannot be used: when warming up, the tree gives a resin that can severely burn the skin. Alternatively, you can combine wood species, but this option is only appropriate for horizontal installation and is done for smell, not for practical reasons.

Most often, the vertical method of placing the lining is used to cover the steam room from the inside. To begin with, they make a special marking, the walls are covered with waterproofing, and only after that the lining is installed.

You can also use a cladding board for interior decoration. It is a versatile material, moreover, it is extremely resistant to all "bath" negative influences: high temperatures and humidity. The tiles are easy to care for and durable, besides, by laying out the bath with tiles, you will get the most unusual structure of all.

The walls must first be insulated from moisture, and then a special plaster mesh should be attached to them. Next, you need to plaster everything. The tile is laid on the glue mortar. Be sure to wipe the seams with a water-repellent and antiseptic compound in order to achieve a presentable look for many years.

Outside, timber baths are usually sheathed with siding. So they are protected from many climatic influences, including rain and frost. Siding will definitely need to be left for a couple of days, having previously spread it on a flat surface. So they get rid of kinks and bends. It is important to keep an eye on which siding you choose: you need a moisture resistant option.

To lay the siding, the walls are grounded, crate is made. It is also necessary to make additional insulation. Waterproofing is done with a special film. After that, the elements are attached, leaving a small gap between the insulation and the finishing cladding itself. All work is carried out from the bottom up. At the end, platbands are installed.

A block house is also used for exterior decoration. Most often, it is chosen in cases where the bathhouse was built from a cheaper debarked log, but you need to create the appearance of a rounded one. The material just faithfully imitates a calibrated frame. It must be remembered that the panels of the block house must be properly prepared before installation: treated with antiseptic solutions or mixtures.

To fix the panels, it is necessary to make a crate. For installation, special climbers are used. Fastening is done from top to bottom, you only need to move horizontally. Further, windows, doors and corners are decorated with platbands and baseboards.

You cannot make thermal insulation when working with a block house, otherwise the tree will rot.

Advice

As professionals say, the process of building a log bath may not be as difficult as it seems.

They give several recommendations that will help to cope with the construction and decoration of the bath with high quality and as soon as possible:

- Do not neglect the time set aside for shrinkage. In addition to the fact that the bathhouse can "lead", it will soon lose its height. The installation of expensive equipment (boiler or furnace) should be carried out only after complete shrinkage, otherwise there is a risk of spoiling expensive structures.

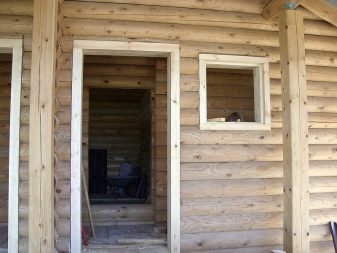

- Doors and windows also need to be cut only after the wood has completely shrunk. This is due to the fact that the sections can be deformed, since the frame does not always dry out evenly.

- To save money, it is worth buying wood in the winter. During this period, prices for it are an order of magnitude lower. Various promotions and sales are also held, which will save even more financial resources.

- Attention is drawn to the knotty nature of the timber. So, the smoother the logs you choose, the easier it will be to work with them. Rounded timber is easiest to handle, but the most expensive.Keep in mind that the smoother the wood, the more expensive it is.

- Do not under any circumstances finish the bath with chipboards. Under the influence of moisture, they are strongly deformed, swell, and when heated, they release toxins into the air, which are dangerous to human health.

- In order to lower the humidity in the steam room at your own discretion, it is worth equipping it with a ventilation system. You can turn it on and off as you wish, achieving the ideal microclimate.

- If you want to reduce the likelihood of a fire, be sure to treat the logs with a fire retardant.

- It is important to remember about the need to treat the calibrated timber with all kinds of antiseptics, since it decays very quickly, collapses, and becomes infected with fungi and mold.

- If a timber is chosen as a material, and not a log house, then the shrinkage time will greatly decrease. This is due to the fact that the timber has already been processed and dried, which cannot be said about freshly cut timber.

- Be sure to take care of fire safety: get a fire extinguisher and place it where you can safely reach in case of fire. It doesn't have to be a steam room. The dressing room, in which the oven is located, is ideal.

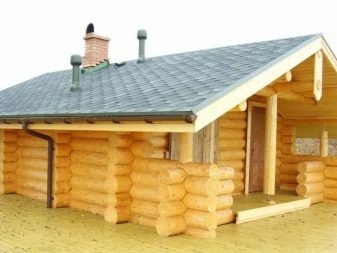

Beautiful examples

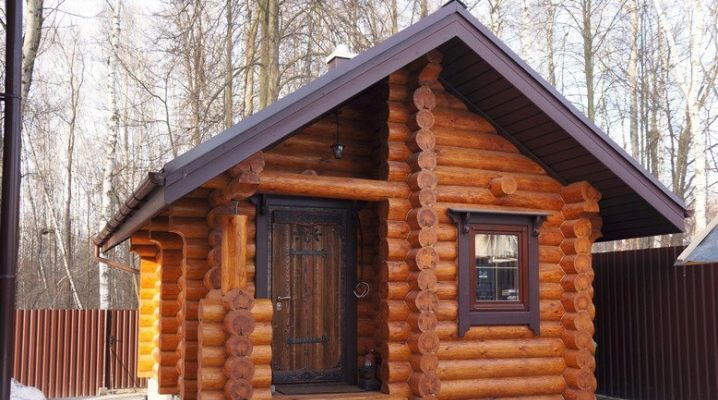

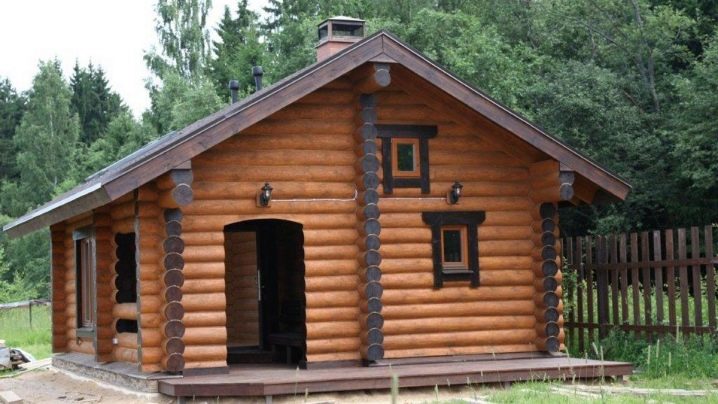

A beautiful bathhouse built according to all the rules. The good quality of the structure is immediately evident: such a structure will last for more than a dozen years. The bathhouse is equipped with two heating systems, which is very unusual.

It is not necessary to build a bathhouse from rounded logs to make it look representative. Planed logs look unusual and original. This design attracts attention, decorates the site.

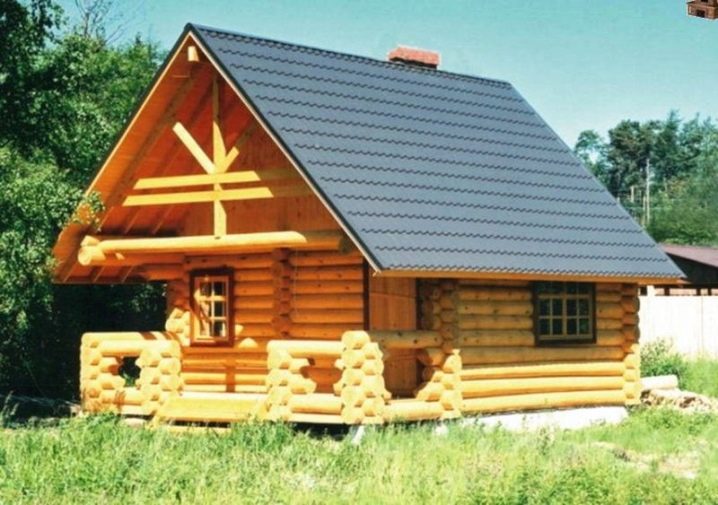

An extremely unusual large-diameter log sauna. Please note that such accent buildings can only be placed under the appropriate conditions, placing them against the background of a forest or matching them to a house already built in the same style. It is also extremely difficult to achieve the optimal level of thermal insulation, so it is better to entrust such construction to a professional.

Another bathhouse on the background of the forest. Buildings made of logs of such a large diameter look like a toy, nevertheless, this building is quite spacious and functional, despite its seeming diminutiveness.

In the decoration, you can use interesting and original techniques, for example, highlight the windows with dark ones, thereby complementing the ensemble of the roof and contrasting sections of the log house.

In this case, not a full-fledged room is equipped under the roof, but an attic, on which all sorts of things are stored. There, if you wish, you can arrange a place for storing firewood, but it is not very convenient to run upstairs for firewood every time.

On the second floor, such a bath is equipped with a full-fledged room. If desired, it would be possible to make a small balcony under the roof itself, equipping another corner for tea parties and get-togethers with friends.

Baths often look like full-fledged residential buildings, especially when they have a second floor. Here the second floor is a full-fledged living room, which is well lit, judging by the skylights and the side, and is visited very often.

Baths made of roughly processed logs are a tribute to fashion, ecology and Scandinavian style. Complemented by mirrored doors, the building looks ultra-modern, while retaining the rustic flavor.

A log bath is an excellent purchase that will serve you faithfully for many years. Built with your own hands, it will keep the warmth of intimate conversations with friends or family members, while forever preserving a particle of the builder's soul. If you are still wondering whether it is worth building a log bath, then the answer is unequivocal - yes.

Tips for building a bath are waiting for you in the next video.

The comment was sent successfully.