Bath from blocks: the pros and cons of the design

The bathhouse is a popular structure that is quite possible to build with your own hands. The territory of such a building should be warm, comfortable and safe. To do this, you need to take into account many different nuances. It is especially important to know about the pros and cons of structures made from popular building materials - blocks.

Peculiarities

The bathhouse is not uncommon these days. It is built from different materials. Most often, of course, there are wooden structures. However, such buildings must be carefully looked after so that they retain their original appearance and do not rot over time. In addition, wooden baths are fire hazardous, even if they are treated with special impregnations.

Blocks are an excellent alternative to such demanding materials.

Their use in the construction of baths is not uncommon. Many owners choose just such materials, since they have many positive characteristics, and in many respects they are superior to wood.

The main feature of building blocks is their porous structure. In this case, the size of the pores (as well as their shape) can change chaotically over the entire area of the block. Due to this distinctive characteristic, the mechanical and thermophysical properties of such building materials are not homogeneous. Because of this, the bath must be very carefully insulated not only from the inside, but also from the outside.

It is worth noting that the blocks absorb moisture like a sponge. In the summer season, this feature does not carry anything terrible, but in winter the previously absorbed water will freeze and increase in volume. This can lead to sad consequences - the destruction of blocks. Of course, this problem is completely avoidable. To do this, it is necessary to provide the building with high-quality waterproofing inside and outside.

Advantages and disadvantages

Block building materials have their pros and cons. You definitely need to know them if you plan to use blocks in the construction of a bath. To begin with, it is worth considering in more detail what advantages such elements have.

There are several advantages of such material as blocks.

- A structure built from blocks will not shrink, as, for example, a structure made of wood.

- A steam room of blocks can be built almost immediately after the main finish.

- The construction of such a bath will take a minimum amount of time.

- It is possible to carry out all the repair work without the involvement of outside help, but experts recommend inviting at least one assistant. So the construction will go much faster.

- The final cost of a block bath will be 2-3 times lower than in the case of the construction of a steam bath made of wood of exactly the same dimensions.

- Block materials are absolutely safe for human health. They do not contain hazardous chemical compounds, therefore, even at high temperatures, they do not emit harmful substances.

- The blocks are relatively lightweight. Thanks to this characteristic, you can significantly save energy and money on the preparation of a high-quality foundation.

- Many consumers choose block materials for construction because they do not support combustion.

- The block bath is not subject to decay.

- The blocks are easy to maintain.They do not need to be regularly coated with antiseptic compounds, as is the case with wooden buildings. Block materials are not susceptible to the formation of mold and mildew.

- Walls built from such raw materials are "breathable" due to their diffuse properties.

- Many types of blocks, for example, gas silicate ones, boast good heat and sound insulation properties.

- The service life of quality blocks is very long.

As you can see, block structures are very durable and wear-resistant.

Currently, many owners choose block materials for the construction of baths (and not only).

However, these products also have their drawbacks.

- The blocks absorb moisture, so the bath must provide high-quality waterproofing, otherwise the material may simply collapse.

- A block bath requires a vapor barrier. This is due to the fact that condensation almost always accumulates inside walls made of such materials, therefore, one cannot do without vapor barrier materials.

- Blocks are durable materials, but in this matter they are inferior to bricks.

- The popular gas silicate blocks contain aluminum powder and lime. These components reduce the positive characteristics of the material.

Many problems associated with block baths can be completely avoided if they are made with high-quality construction, as well as take care of hydro and vapor barrier in advance.

Projects

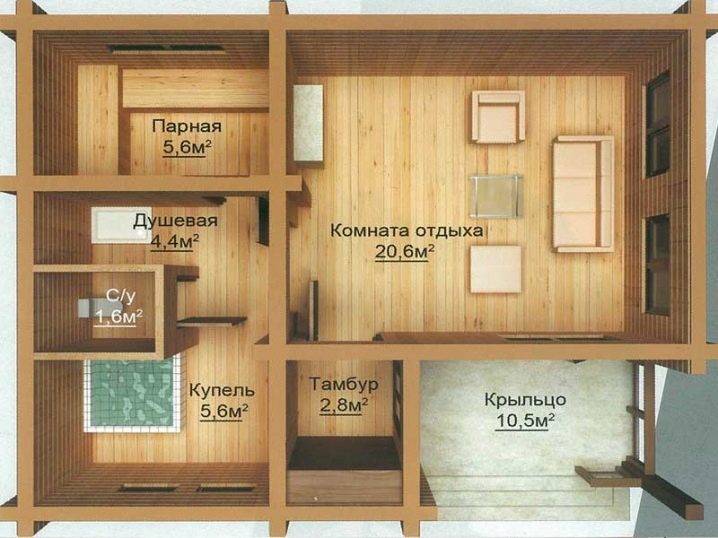

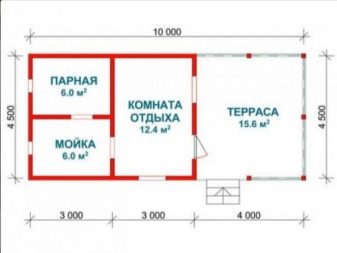

Currently, the bathhouse is a multifunctional space that is used not only for washing, but also for good rest. Based on these goals, modern projects of block baths are being developed. In addition to the main premises (steam room, washing room), this building may contain a cozy relaxation room, a small terrace, an attic or a swimming pool. The size of the latter largely depends on the dimensions of the structure itself.

The most common are attractive bath designs that include a relaxation room.

As a rule, it also serves as a kind of locker room.

Most often, in terms of its area, the relaxation zone exceeds the rest of the premises. This is due to the fact that a table, armchairs or chairs and other necessary pieces of furniture that need enough free space must be placed in the rest room.

The most common project types include the following options.

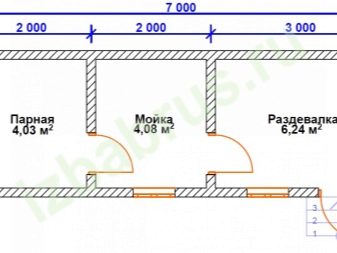

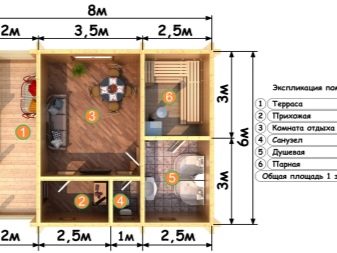

- The budgetary and optimal option is considered to be a block bath with dimensions 4 x 6 m... With this structure, you can divide all the available space in half using a partition. One of the isolated halves of the building can also be divided in half or in proportion. In the largest room, a comfortable and attractive seating area should be organized. As for small rooms, it is worth placing a steam room and a washing room in them.

When building a block bath with a relaxation room, be sure to keep in mind that a vestibule or a small dressing room must be provided in the building, separating the inner and outer parts of the structure. Thanks to such additions, cold and frosty air will not penetrate into the room during the winter season.

Such a bath can be supplemented with an attic and a comfortable second floor can be organized in it.

Most often, such a decision is addressed if there are no other living spaces on the land plot. Also, they often refer to such structures when decorating a plot in the country. The attic is a great place to spend the night after staying in the recreation area.

- Another popular and widespread project is baths with a size of 3 by 5 m... Such buildings are quite spacious. Several people can easily steam in them without any hesitation. In addition, such buildings are often complemented by terraces.

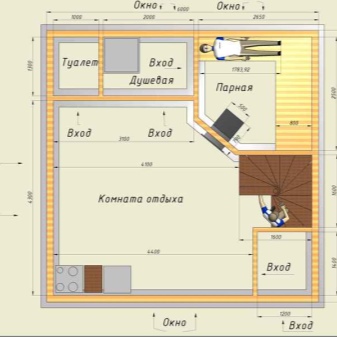

When developing a project for a bath with dimensions of 3 by 5 m, it is necessary to organize several isolated rooms. Without them, the resulting design will be incomplete.

The first room a person will enter can be a dressing room. It should be such that you can leave clothes in it. In the interior of such a bath, it is necessary to place a small cabinet in which there is free space for storing all things. Many owners install an additional box in such baths, in which they store fuel (firewood or coal) separately.

After the dressing room, you can arrange a rest room.

Even in projects of very small baths, it is necessary to provide for this room. In a 3x5 m building, a small table and a few chairs can be placed in the relaxation room.

A sink or shower should be arranged immediately behind the break room. These spaces are necessary so that the users of the bath can cool off after they steam up the body. These rooms should have a simple and uncomplicated interior design. They can accommodate several small benches, a shower and a clean container filled with water. Currently, many owners choose one shower stall for arranging such spaces, abandoning the classic sink.

The main room of the bath is a steam room. Here it is necessary to place the oven, as well as comfortable wooden benches. All of the listed rooms must be in any bath. In addition, a building with dimensions of 3x5 m also allows the installation of a small terrace or attic.

- In a bath with dimensions 5x4 you can allocate the main space for a large rest room, and leave the rest of the area for a sink and a steam room, which have approximately the same dimensions. In addition, such a building looks much more attractive if it is supplemented with a wide terrace. Similarly, it is possible to design a 4.5 by 4.5 m bath.

- A cozy bathhouse can be equipped and in a small building with dimensions of 3x4 m (or 4x3 m)... In this case, the main area can be allocated for a relaxation room and a steam room, and leave a minimum space for a sink. The dressing room in such a bath should also not be made too large.

Immediately after the dressing room, you can organize a small relaxation room and put a compact table in it, as well as a couple of chairs. You can get by with a not too large sofa and place a coffee table in front of it. This area should be separated from the rest of the space by a partition, and a spacious steam room should be installed behind it. It can be divided by another partition and equipped with a washing space in the resulting small corner. In such conditions, a narrow shower stall will look best.

- Large bath with dimensions 10x4 m will be issued in any of the listed formats, however, there will be much more free space for each room. In such conditions, it will be possible to equip a recreation room equipped with a large number of furniture, following a large attic or an area with outdoor gazebos.

It is also permissible to divide the frontal space into a vestibule and a terrace, and after them form a rest room.

A partition should be placed behind it to close the three remaining zones - a shower room, a steam room and a bathroom (if you want to install it in the bath).

All bath projects are similar to each other. Any building should have a washing, steam room and relaxation room. Additionally, the building can be equipped with a spacious attic or a neat terrace. Some owners even combine such structures with a garage. In this case, it is recommended to contact specialists who can competently draw up the correct drawings of such buildings.

Materials (edit)

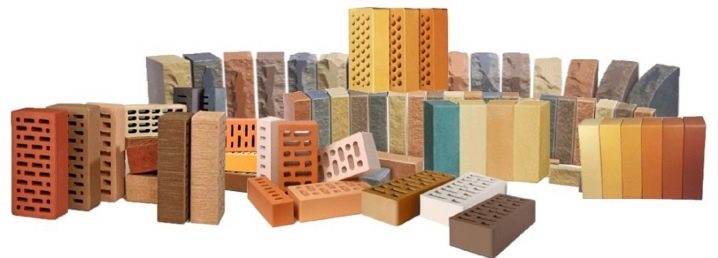

There are several types of building blocks from which reliable and durable baths are made. Each raw material has special characteristics:

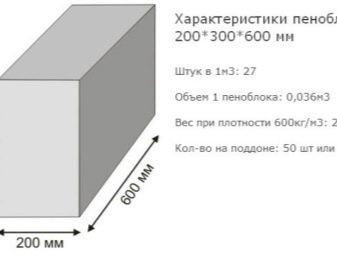

Aerated concrete

Baths are often built from a gas block. This material is very popular and affordable.

It has many advantages:

- Low weight. A block with dimensions of 30x25x60 cm weighs only 30 kg. If you decide to lay a brick in the same volume, then you will need 22 elements, the total weight of which will be 80 kg.

- High heat conductivity. Aerated concrete has a cellular structure that provides an excellent heat-conducting effect. Such material perfectly retains heat in the room, and in hot summer creates a pleasant coolness.

- Fire safety. Aerated concrete blocks are made from mineral components that are not flammable and combustible. For this reason, such building materials can easily withstand exposure to open fire for 3 hours.

- Frost resistance. High-quality gas blocks are not afraid of low temperatures.

- Strength characteristics.

- Profitability. Due to its size and weight, aerated concrete is laid much faster and easier than the same brick.

- Ease of processing. An aerated concrete block can be given almost any shape. To do this, you can use a regular hacksaw. This material is easy to cut and drill.

- Environmental friendliness. Aerated concrete blocks are environmentally friendly. They do not contain toxic substances released at high temperatures.

The thickness of gas blocks can be:

- 75 mm (suitable for additional insulation of rough floors);

- 20-25 mm (used for utility and household buildings, for example, garages);

- 375 mm.

There is also aerated concrete of the INSI brand, which is widely used in the construction of houses.

Such materials are large, so they do not take much time to install. This material is autoclavable. It is distinguished by seismic resistance and increased strength.

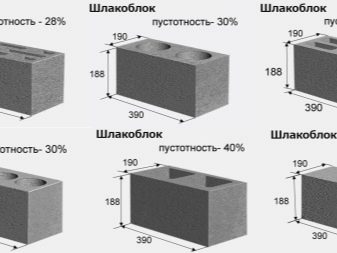

Cinder block

Cinder blocks are a building stone, which contains the following components:

- volcanic ash;

- crushed granite;

- sand;

- broken glass;

- expanded clay;

- gravel;

- crushed stone;

- sawdust.

There are several types of cinder blocks:

- Full-bodied and hollow. Solid parts are highly durable. They are often used to make strong foundations, basements and even columns. Hollow parts are used in the construction of walls and partitions inside different rooms.

- Decorative blocks for cladding. These materials have appeared on the market relatively recently. They have a decorative coating that is located only on one or two sides of the block.

- Partitional. These cinder blocks are used in the formation of partitions. Such materials provide precise floor geometry. In addition, during the installation process, the solution will be significantly saved. Installation of lightweight partition cinder blocks takes little time.

- Torn, chipped. Such blocks also have a decorative coating, but it imitates "torn" or chipped bricks. Most often, such materials are used to decorate fences and various buildings.

- Colored. Such cinder blocks are used in the same way as conventional materials. Often they are used when installing fences or poles that perform a decorative function. You can achieve the desired shade in the process of making such cinder blocks - just add crushed red brick or multi-colored chalk to the mixture.

- Fundamental. In another way, this type is called artificial wall stone. It has excellent strength characteristics and a very long service life.

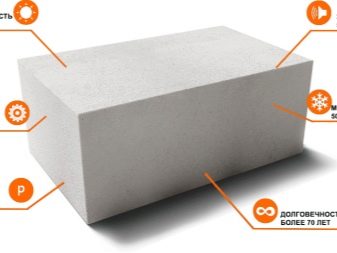

Gas silicate

The bath can also be built from gas silicate blocks. A distinctive characteristic of these building materials is that there are voids in their structure that occupy 50% or more. Thanks to this characteristic, the blocks are lightweight, and also do not exert an impressive load on the foundation.

It is also worth noting that gas silicate blocks are distinguished by good soundproofing and thermal properties, which are provided by the structure with cells.

A bathhouse built of such materials will retain heat for a long time.

Gas silicate blocks are often used in the construction of baths because of the following qualities:

- fire safety (not flammable);

- increased frost resistance;

- easy and quick styling;

- simple processing;

- environmental friendliness;

- increased vapor permeability.

However, it should be borne in mind that this material absorbs moisture, which leads to an increase in its density and strength, and this negatively affects the non-thermal and sound-insulating properties of the blocks.

Sand block

Sand blocks (sand-cement blocks) are made by mixing a combination of cement, sand and water. This composition is standard.

Sand blocks are very popular not only because of their economy, but also because of their positive characteristics:

- Such blocks have excellent strength characteristics. They are not afraid of negative external factors.

- Sand block baths are not susceptible to rust and decay.

- These building materials are made from environmentally friendly and safe components.

- These blocks also contain voids, so they have sound and heat insulation properties.

- Almost do not absorb dampness and moisture.

- Have an affordable price.

The disadvantages of cement-sand blocks include their low thermal conductivity.

Experts recommend additionally insulating these materials, especially if you use them in the construction of residential premises and baths.

It should be borne in mind that solid sand blocks have a more impressive weight than hollow elements. That is why it is necessary to prepare an appropriate foundation for such building materials.

Arbolite block

Arbolite blocks are often used in the construction of baths. These materials are distinguished by increased strength, which is provided by the appropriate structure and composition. In addition, wood concrete elements are not afraid of unfavorable climatic conditions and various precipitation. They do not absorb dampness and moisture, and also do not deform when in contact with them.

Arbolite blocks can be safely used in the construction of baths, since they are not flammable - they contain not only cement, but also special chemical impurities that provide these properties.

Many consumers prefer wood concrete blocks because they have an affordable price, especially when compared to bricks.

There are only two types of wood concrete blocks:

- constructional;

- heat insulating.

Twinblock

Twinblock is another type of honeycomb blocks. It is high-tech and autoclave. Like other types of similar materials, it is lightweight and does not exert strong loads on the foundation.

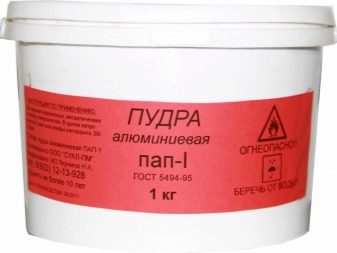

The twin block contains the following components:

- cement;

- lime;

- aluminum powder;

- water.

These blocks are easier to work with than cinder blocks as they are lighter.

In addition, they are very easy to cut and saw. However, the main disadvantage of such blocks is their high cost - 3000 per m3.

Design

Many people believe that a bathhouse is a room in which it is impossible to show imagination to the maximum when drawing up an attractive design. In fact, this is not the case.

In the bath, it is quite possible to build a kind of living room with a large table and several chairs, as well as a cozy sofa, opposite which a wall-mounted TV will find its place. This layout can be used even in a small building, if you use small furniture or convertible folding models.

Inside, the room can be sheathed with siding or panels that imitate timber. Such coatings will look very attractive and appropriate in a bath.Against their background, you can place furniture made of wood, as well as wall and ceiling lamps made of antique-style metal.

If you want to bring a natural touch to the rest room, then you should take a closer look at decorative brick - it will look great on the walls in combination with wood trim.

Some owners complete such a bath interior with real fireplaces or fireplace stoves made of brick, stone or their imitations.

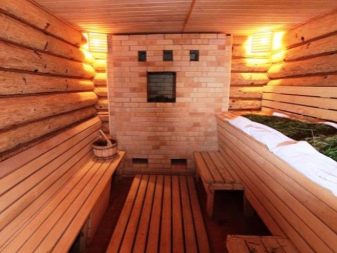

As a rule, a large number of wooden parts are also present in steam rooms and washing rooms. Here you can also dilute the finish with stone. Lighting devices in such spaces often have a laconic look that does not attract too much attention.

How to build with your own hands?

A bathhouse from blocks can be built independently without attracting specialists, whose servants are often very expensive.

The main thing is to adhere to the phased algorithm for the construction of the structure:

- First you need to draw up a draft of the future bath.

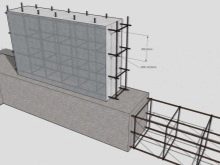

- Then you should proceed to laying the foundation. To do this, you need to make a markup on the site, dig a trench and make a 15 cm sand pillow at its bottom. The sand must be poured with water and tamped.

- Now you need to make a timber formwork above the trench. Using a level, it is necessary to beat off the upper (horizontal) surface of the foundation on it.

- In the inner part of the formwork, a frame should be made of reinforcement.

- Next, pour concrete into the formwork.

- Now you can build walls. It is especially important to lay the starting row of blocks. Using a cement-sand mortar, you need to lay out the blocks on the prepared waterproofing.

- The next rows must be placed on special glue.

- At the end of the installation, reinforcement is laid on top of the walls, and a Mauerlat is made.

- After that, you need to move on to the construction of the roof structure. To do this, it is permissible to use rafters and lay waterproofing on them.

- They should also be trimmed with a counter lattice, on which the main lathing must then be laid.

- After that, it is worth moving on to the installation of roofing materials.

- After completing all the listed works, you need to finish the resulting bath.

Owner reviews

Nowadays, block baths are not uncommon. Such structures are chosen by many owners, as they are more durable and less demanding in terms of maintenance. However, some users argue that wooden buildings still look much better than block buildings. But not all of them coped with the independent erection of such structures.

Also, people often refuse to build a bath from blocks, referring to the fact that they absorb moisture, which is why they are then destroyed. Of course, in this case, wooden options are in no way superior to block buildings, since they are even more afraid of moisture. In order not to encounter deformation of block materials, it is necessary to provide them with high-quality waterproofing.

Consumers were pleased with the fact that working with blocks is not so difficult.

It took many people a minimum amount of time to build a bath from such materials. In addition, for most buyers such construction sites were quite inexpensive.

Also, users note that any blocks do not exude unpleasant odors at high temperatures.which cannot be avoided in the bath. They do not get damp or mold or mildew. Even after a long time, block materials do not rot, as, for example, natural wood.

Reviews of block baths are both positive and negative. Of course, a lot depends on the correctness of the construction of the structure, as well as the quality of the materials used.

Beautiful examples

Many consumers are skeptical about block baths, explaining this by their unsightly design. In fact, such buildings can be made very stylish and attractive, not only inside, but also outside.

For example, a small structure with a triangular roof and steps leading to the dressing room can be decorated with light-colored siding panels. The lower part of the building should be lined with decorative brown bricks around the perimeter. In such a bath, tiles of blue or purple color will effectively stand out.

From foam blocks, you can build a beautiful bath with a terrace and finish it with a dull lemon-colored facade plaster.

At the entrance to the building, place brick columns and install a red tile roof on top, which would cover the entire building as a whole (together with the terrace). Plant green plants and flowers around. As a result, you will have a very effective bathhouse.

A block bath can be made laconic, but no less attractive, by playing on the contrast of walls and roofs. For example, external finishing of block ceilings should be done with snow-white or beige plaster / paint, and brown for the roof. Install high plastic windows and doors in such a structure. This will make the sauna more stylish and modern.

You will learn more about the aerated concrete bath and its features from the following video.

The comment was sent successfully.