The foundation for a bath: varieties and features of DIY construction

The service life of any structure largely depends on the laying of a reliable foundation. The bath is no exception: when erecting it, it is necessary to take into account the characteristics and features of the installation of the base. This article discusses the varieties of the bath foundation and the features of its construction with your own hands.

Device

The foundation is created not only taking into account the type of soil on which the bath will be built, but also the materials of the future foundation. Soil information should be recorded from previous construction work on the site. If for some reason it is absent, then geological surveys must be carried out independently. It is important to understand that a quality foundation cannot be built on unexplored soil.

Geological exploration is carried out by special organizations: a drilling machine makes wells from which soil samples are taken. In a special laboratory, the soil is examined - its chemical composition and physical and mechanical properties are determined. The excavations are carried out along the entire perimeter, below communications and at different depths in order to obtain a complete geological map of the area. This process takes a lot of time and money, but there are also more economical options.

The basic properties of the soil can be determined independently. To do this, it is necessary to dig several wells, trying to make the well as deep as possible. The ideal will be a hole that reaches the depth of soil freezing. As a tool, the craftsmen are advised to use a garden drill. The dug wells determine the thickness of the fertile soil layer, the boundary of groundwater and the composition of the soil.

The foundation must pass through the soft fertile layer and rest on a harder structure. If the soil on the territory is heaving (hills and cracks are visible on the surface), then the foundation must be lowered to the level of freezing of the soil. The soil around the supports is covered with a mixture of sand and gravel so that the groundwater does not displace the base when it freezes. A shallow foundation is laid only under standard conditions.

If there are sharp elevation changes at the construction site, then a pile-screw foundation is suitable for such a territory.

It is not recommended to install piles in areas with elevated groundwater levels. The interaction of the supports with water will lead to rapid corrosion and subsidence of the foundation. Before installing the piles, it is necessary to treat with a special solution that protects the structure from moisture.

For moving soils, a pile-grillage foundation is suitable. This type is well suited as a base for brick and block structures. Piles hold the structure in case of landslides and displacements, providing stability to the foundation. The grillage is a tape that connects the supports, designed to evenly distribute the load. It is made from metal, wood or reinforced concrete.

The columnar foundation is intended for regions with deep soil freezing. Also, this type of foundation is used in the construction of buildings in waterlogged areas, marshy soils. In areas subject to soil movement, a columnar foundation is not installed. It does not tolerate shifts and landslides.

The most reliable type of foundation is monolithic.The concrete slab is able to withstand any difficult conditions while maintaining integrity and stability. One-piece base evenly distributes the load on the ground, preventing settlement. The main disadvantage of such a foundation is the high price.

Among the materials for building the foundation for a bath, preference should be given to natural materials. For a pile foundation, wood is better. It is customary to build slab and strip foundations from heavy materials - stone and concrete.

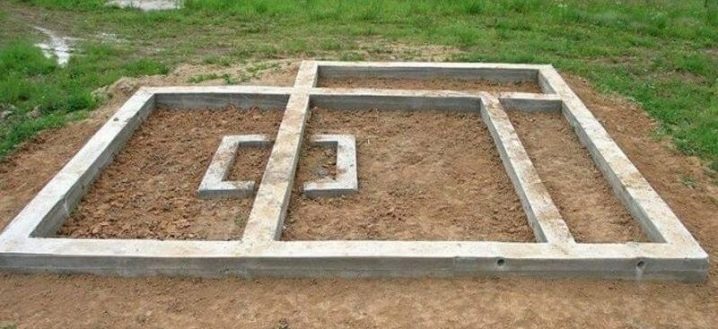

The tape structure is the most reliable type of foundation. The masters advise to choose this option for those who want to do the work with their own hands. This type of foundation is suitable for any size structure. It is a tape of concrete or brick that rests on the ground below the water table. No more than twenty centimeters of the base are left on the surface.

A strip foundation is suitable for any structure, but experts identify several of the most optimal cases for installing such a foundation:

- The basement is used for installing a pump and communications, storing household items. The basement walls must be protected from the effects of variable water levels, wind and low temperatures.

- The building of the bathhouse is very heavy and reaches an impressive size. The strip foundation takes the load from the structure well and transfers it to the soil. This type of base is suitable for brick buildings.

There are several methods for assembling a strip foundation. Each of the methods has a number of pros and cons. Brick strips are installed on dry sandy soils. With high groundwater, the structure is placed on a brick-crushed stone pillow, reinforced and poured with a concrete screed. The brick strip foundation is lightweight and easy to install.

It is important to understand that to create such a foundation, you must choose the right material.

The foundation is assembled only from red bricks. White silicate material is not resistant to interaction with water, therefore it will quickly collapse. Seams between bricks must be treated with waterproofing mastic - cement has a good culvert capacity.

A strip foundation made of concrete blocks is suitable for a small bath. Reinforced concrete is a heavy material, so large pieces can only be erected with construction equipment. Parts measuring 20 by 40 centimeters are considered optimal. Such blocks are installed in a checkerboard pattern on a sandy substrate. Installation of the foundation can be completed in two days.

The stone foundation is erected from river stone and cement. Another name for this type of foundation is rubble concrete masonry. This type of foundation is easy to install and has a low cost price. Stones should be flat and uniform in size. Layers of masonry are poured with concrete.

The pile foundation is suitable for light buildings, easy to manufacture and reliable in operation. The construction of this type of base requires few materials, which significantly reduces the cost and time for its installation. It is recommended to install piles for beginners, because they do not require special construction skills.

The pile foundation is not suitable for heaving soils - the supports do not take horizontal loads well. To protect the foundation from destruction, it is necessary to reduce the distance between the piles. Hardwood foundations are more resistant to water. Nevertheless, wooden piles are practically not used in construction today.

There are about twenty pile options in construction. Of these, one can single out three types of supports suitable for low-rise buildings and baths:

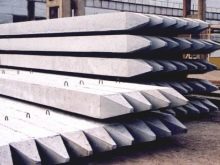

- Driven reinforced concrete piles. This type is rarely used in the construction of baths. The supports are heavy enough that it is impossible to hammer them in without the help of specialized equipment. The cost of such work can be very high.The indisputable advantage of driven piles is their reliability.

- Screw metal supports can be installed manually. Such a foundation is easy to install, because it does not require special skills. A significant disadvantage of steel is its high thermal conductivity. This type of foundation is not suitable for floors without insulation. With such a base arrangement, an unheated room will always be cool.

- Bored piles - the most common way to build a foundation on supports. Installation work requires a good investment and a lot of labor. The plus of such a basis is the saving on materials.

Supports are located at the junction of the walls. The distance between the piles should not be more than two meters. The popular diameter is 20 centimeters. With an increase in the cross-sectional area of the pile, its bearing capacity increases, but the risk of displacement of the support under the influence of heaving forces increases. The foundation is lowered below the freezing boundary of the soil. On loose soils, piles are installed on the supporting layer.

The columnar foundation serves as the basis for wooden buildings. It does not perceive high loads, so it can sink under a stone and brick house. Walls on such a base are deformed and covered with cracks. Subsequently, the building will collapse.

To make the structure last a long time, craftsmen use a special technology and special technique. This process is very expensive, which is irrational for a modest budget.

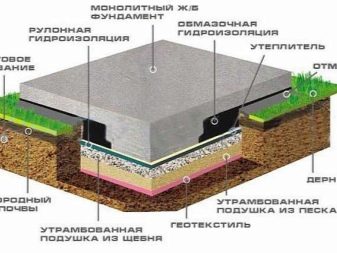

The monolithic base is a slab mounted on a sand and crushed stone substrate. The thickness of the pillow can reach from twenty to fifty centimeters, depending on the type of soil and the characteristics of the structure. The foundation can be shallow and shallow.

This type of foundation is distinguished by its physical and mechanical properties: it is considered the strongest and most durable. The sole occupies a large area, therefore it takes up all the load from knowledge. The weight is evenly distributed and the ground pressure is reduced. Reinforcement is placed to reduce damage to the foundation when it is installed in frosty heaving soils. A monolithic foundation serves as a good foundation on unstable and waterlogged soils.

Among the advantages of a monolithic screed, there is an affordable installation price. During the construction, there is no need to involve specialists with complex equipment. The screed is poured from the concrete mixer into the mold. The monolithic construction allows for reduced excavation work. This type of foundation has a long service life due to the preservation of integrity.

The main disadvantage of the base is the impossibility of building a basement. The specifics of the installation does not make it possible to design a room below the basement level. Also, this type of foundation requires a large amount of material and reinforcement.

Laying does not require specific equipment, but it cannot be done in adverse weather conditions.

The foundation is a subfloor and therefore needs to be insulated. A monolithic screed allows you to arrange a heated water floor. It is necessary to remember about waterproofing and the device of an insulating structure. Otherwise, the room will be cold. A “carpet” made of insulating materials can be used as a backing for a cement screed.

The insulating “cake” is corrosion resistant even when interacting with groundwater. Modern building materials are durable and highly durable. Monolithic slabs, like the substrate, are mainly arranged on difficult soils.

All building materials must meet stringent requirements in accordance with regulatory documents.

Preparation and calculation

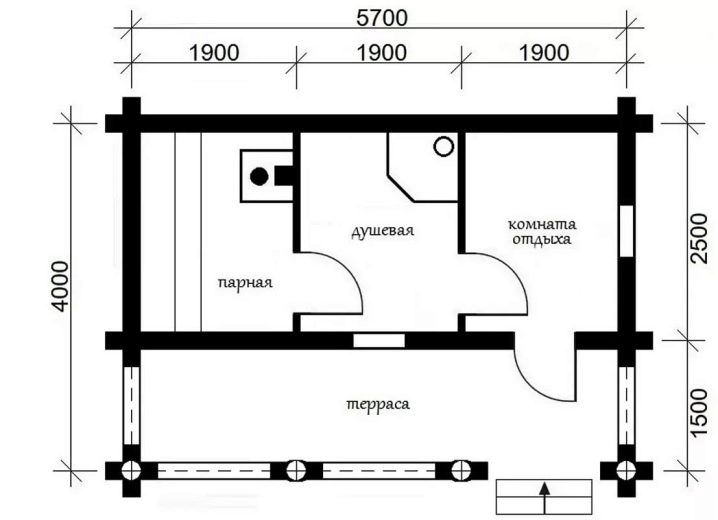

To begin with, you need to draw a diagram of the site in compliance with the scale, designate a site for a bathhouse and conduct communications to it. The location of the building largely depends on the drain device.When connecting the water drain to the central sewerage system, the bath can be located anywhere in the suburban area. If the drain is isolated, then it is better to place the building away from water bodies.

The pre-bath area must be fenced off from strangers - a fence is needed on the site. The building can be surrounded by a hedge. All additional plantings or outbuildings are also marked on the terrain plan.

Work begins with cutting off the topsoil. Next, the site must be leveled. This can be done using a special technique. Differences in height should be avoided - this will complicate the markup and make it impossible to lay the foundation evenly. The marking is carried out on the basis of the project on paper, therefore, the further arrangement of the foundation depends on the accuracy of the image of the terrain.

The outer perimeter of the foundation is marked with a tape measure and a building angle. The extreme points are marked with pegs through which the cord is pulled. It is necessary to check the perpendicularity of the corners at each stage of the marking. To check the accuracy of the placement of marks, the diagonals of the structure are measured. If the building is rectangular or square, then the diagonal measurements will be equal.

For the accuracy of placing the peg, you must use a special geodetic technique - theodolite or level. You should check the length of each side and the degree measure of the angles several times. The stretched cable is the height level of the future foundation. After designating the outline of the building, the area is broken down.

If the future foundation is strip, then from the outer edge it is necessary to retreat a distance equal to the future thickness of the screed.

When installing piles, pegs mark the location of future wells. Their number depends on the area of the bath. The step of workings should not exceed two meters. Piles must also be located at the junctions of the load-bearing wall with partitions. If the number of storeys of the future building reaches two or more floors, then the distance between the supports must be reduced. Dense soil allows you to reduce the number of piles, and loose soil, on the contrary. The depth of the well depends on the type of soil: in heaving soil, the pile must be lowered 30-50 centimeters lower.

A monolithic foundation can be poured without preliminary calculations - the optimal base thickness should be up to 25 centimeters. Reducing the screed may require additional reinforcement reinforcement. With a foundation thickness of thirty centimeters or more, a strong structure is obtained, but such a construction cannot be called economical. It is customary to cover a substrate of sand and gravel in layers not exceeding ten centimeters in thickness.

The insulation slab should not exceed ten centimeters. The concrete base also needs a reinforcement frame. According to regulatory documents, for reliable construction, the reinforcement should not be less than 0.3 percent of the total mass of the structure. The dimensions of the rods can be calculated with your own hand based on the cross-sectional area of the slab. To save time, the craftsmen are advised to install a frame made of twigs 12-13 millimeters in diameter in two tiers.

Layout and excavation

As described earlier, the marking is carried out according to a previously drawn up scheme taking into account the peculiarities of the type of foundation. The course of the rope between the peg - marking the lines of the walls of the foundation. After contouring, it is necessary to develop trenches for laying the foundation. The depth of excavation depends on the properties of the soil and the type of foundation.

The construction of the strip foundation begins with the excavation of a trench. After marking and cutting off the top layer, the surface is covered with a sand-crushed stone pillow. Before backfilling, the rough surface must be tamped using vibration devices. For small buildings with dimensions of 4x6, 6x4, 5x5 meters, you should not design a deep foundation. A substrate 300 millimeters thick will be enough.

The thickness of the sand backfill varies with the type and properties of the soil.If the soil is water-saturated, then the substrate should be increased to 40 centimeters. The sand layer is laid horizontally, abundantly wetted with water and rammed. A large pillow is divided into layers 5-7 centimeters thick and laid gradually. After backfilling and compaction, it is necessary to leave the coating for two or three days until the soil is completely dry.

Next, formwork is made with a height of about 50 centimeters. The formwork can be made from any plank or similar material. The structure can be used many times if it is well cleaned and carefully stored under a layer of polyethylene. The sheer walls of the formwork are propped up with stakes or special struts.

The frame must be strengthened so that the concrete mixture does not destroy the structure during the drying process.

Starting at the edges, you need to make a flat, horizontal surface. Walls are much easier to install on a flat base. The shields are fastened with nails, and the joints are coated with soil. The accuracy of the work can be monitored using a laser level. After the formwork, the first layer of the screed is laid on the bottom and the reinforcing cage is immersed in it. The entire volume of the formwork must be filled with cement, leveling the surface.

Excavation work on the device of a pile or columnar base begins with drilling wells. As with strip foundations, a crushed stone backing must be laid out for the piles. The pillow usually does not exceed 250 millimeters. Next, they lay out the pillars of rubble or brick. In some cases, an apparatus is immersed in the depleted holes, filling the well with concrete. This is how concrete piles are made.

DIY construction

It is not so difficult to fill the slab foundation with your own hands. Between the heat insulator layer and the concrete screed, it is necessary to lay a layer of polyethylene. This is done so that the concrete mixture does not leak: water from the composition can penetrate into the upper layers of the soil. This will lead to a violation of the consistency of the cement mortar and uneven shrinkage of the base. Layers of polyethylene are laid with an overlap, the seams are glued with tape. After pouring the blocks, the structure is left to dry completely. The depth of the support is calculated in advance.

Small screw piles can be installed manually. Supports up to 2.5 m long are screwed in by two people, the third monitors the accuracy of the work. It is better to choose piles with a height of about one and a half meters. After installing the last support, the evenness must be checked with a laser level. To cast concrete piles, first, a metal base is screwed in, and then it is poured. As the concrete hardens, the supports are connected with a grillage from a channel. Such a device ties the piles together and distributes the load from the building evenly to each support.

There is a step-by-step instruction for casting a pile grillage. To install the grillage, you must first create a reinforcing cage, mix the concrete solution and prepare the form from the formwork. The form can be made by analogy with the technology of casting a strip foundation - from shields or a wooden frame.

A mesh is attached to the reinforced piles; along the entire contour of the building, its step should not exceed thirty centimeters. Its installation is carried out on special fasteners inserted into the holes on the pile. The metal frame is partially inserted into the piles, aligned with the longitudinal whips. In the case of concrete piles, the reinforcement is connected to metal ropes protruding from the supports.

The formwork is straightened, the frame must be flat. The uniformity of the distribution of the mass of the structure over the surface will depend on the quality of the work done. Curvature of the structure will lead to uneven soil placement. Pouring concrete into the formwork is carried out starting from the heads of the piles. Strengthening the structure is achieved by deepening the supports into the grillage for a short distance.

If it is not possible to fill the grillage with concrete, then the craftsmen recommend making such a structure from a bar.

For a wooden building, it will be the most profitable. The wood must be pre-dried and treated with a special moisture-proof compound. The installation of the grillage begins with cutting the material into fragments - the ends of the beams are cut out in the form of a lock. The structure is assembled by bolting to the piles.

Columnar, strip and monolithic foundation can be made by hand. But in no case should the installation technology be violated. It is better to carry out work under the supervision of a specialist, taking into account all the subtleties. A detailed scheme with a drain is used throughout the entire process of work, so do not underestimate this stage of preparation.

Materials must be selected in accordance with regulatory documents - each product must have a quality certificate.

Oven base

Many novice craftsmen do not know whether it is necessary to install a special base under the oven. The presence of the foundation is determined by the weight of the heating structure. A small stove weighing up to 250 kg does not require additional floor reinforcement. In this case, the coating may not be reinforced, but only treated with a fire protection agent. The material under the oven must be reliably protected from overheating.

For a brick oven, you need to make a special foundation. For such units, the weight can vary from hundreds of kilograms to tens of tons, which creates an increased load on the base of the structure. If the weight of the heating device reaches 750 kg, then in this case it is necessary to design an individual base. The stove creates an uneven load on the floor of the bath, which will lead to partial subsidence of the weak base. Therefore, the foundation of such a bath must be strong, the structure must resist the movement of the ground.

It is possible to build the correct basis only taking into account the depth of soil freezing. For a competent construction, you need to consider a number of important points:

- The supporting structure for the bath is being erected simultaneously with the construction of the basic foundation of the bath. The depth of the additional reinforcement and the foundation of the structure is maintained at the same level. Pouring the screed after mounting the reinforcement is unacceptable due to the difference in the degree of shrinkage. This difference will lead to the destruction of the heating system. For such purposes, craftsmen recommend paying attention to the pile foundation.

- Since the walls of the bath are not erected simultaneously with the construction of the foundation, a distance of 50 millimeters must be maintained between the device of the furnace structure of the future wall. This gap is subsequently covered with sand and compacted well. Such a system resists uneven settlement of the base.

- The dimensions of the foundation must be correlated with the dimensions of the furnace at the stage of developing the design documentation. The boundaries of the foundation slab should protrude beyond the boundaries of the heating system by at least 50 millimeters. The most optimal distance is 60-100 millimeters.

- The chimney should be located as close to the center of the foundation as possible. Such an arrangement of the furnace will provide an equal load on the entire structure. A powerful chimney requires additional protection and reinforcement, therefore it risks creating an excess load on the foundation. Regardless of the choice of the type of foundation, these features must be taken into account.

- When installing a heating system, it is necessary to additionally equip a waterproof layer. Roofing material is lined in two layers and attached to the foundation. As a glue, craftsmen use bituminous mastic. This material will provide additional protection for the structure.

The brickwork of the stove is susceptible to corrosion, therefore, protection from the influence of water is necessary in this case. Also, using a stove increases the humidity level in the room.

Recommendations

There is a wide variety of basement designs, each with a number of advantages and disadvantages. It is impossible to choose the best option, because the choice of the base depends on the characteristics of the territory.When erecting the foundation, it is necessary to consult with professionals, because the duration of the operational life of the bath depends on the competent arrangement of the foundation.

A layer of sand and gravel must be protected with a layer of geotextile. This material can be laid between the layers of soil, bending the edges up. The textile will protect the pillow from silting and erosion. The material passes moisture through itself well, and due to its composition it does not undergo destruction for a long time. Geotextiles are produced in special rolls, which makes them easy to use.

It is necessary to drain water from the bath. To do this, arrange a special drain that goes into the ground.

It is important to remember that the pipe outlet cannot be located in the vicinity of the neighboring areas. You also need to make sure that the used water does not drain into the reservoir.

How to start building the foundation for the bath, you will learn further.

The comment was sent successfully.