Fireboxes for a bath: types and their features

A real Russian bath has always been heated with wood, but a good owner is engaged in preparing them in advance. It is required to prepare a specially designated place so that the wood is at hand, and if you need to report firewood to the firebox, a firebox is used.

Views

Firewood or woodpiles can be classified by construction type:

- portable;

- attached;

- street.

The first ones are compact in size and attractive in appearance, since these are metal or wooden products intended for a small amount of firewood. Street and attached ones represent a small shed or shed in which the main supply of wood for the heating of a bath is stored.

Firewood boxes are made of three types of materials:

- metal;

- vine;

- wood.

Wooden ones can also be both portable and outdoor, you will need to process the material with special means so that it does not deteriorate from moisture, if you want such a product to last a long time. The advantages of such wood burning stoves are low cost, but they have a short service life. Wicker structures are very fragile and are more used as an addition to the overall interior. They are available with or without stand in various sizes.

The most durable and beautiful metal products can rightfully be called, since they are made forged, from a profile pipe or any other blanks. They can be of various designs and sizes, it all depends on the imagination of the master. Such products can withstand a lot of stress due to their strength.

It is worth treating the material with a special agent that will prevent the formation of corrosion. The portable firebox holds exactly as much firewood as is needed for one firebox, so they are installed in the dressing room and do not take up much space.

The advantage of forged woodpiles

Metal, as a material, is much superior in many respects to wood and vines, since it has durability and strength. This is exactly the kind of product that will last for many years if you regularly wipe the metal and make sure that rust does not appear on it. Other advantages include:

- the possibility of using the product not only indoors, but also outdoors, since changes in temperature and humidity do not harm the metal;

- you can make a larger firebox, and it will withstand the load.

There are numerous options for forged products on the market, among them there are real works of art with smooth lines, openwork patterns. Such models differ among themselves in the complexity of execution. Craftsmen offer woodpiles that will perfectly fit both the classic style, maintained in the interior, and the modern one. On sale there are square-shaped, round, oval, crescent-shaped fire boxes.

For convenience, each product has handles for transferring the structure.

How to do it yourself?

It is worth noting that metal woodpiles are not cheap, so some craftsmen try to make them with their own hands. Everyone can master the technology, you just need to have the required amount of material and welding on hand. More complex models with metallic patterns require a certain level of skill, but a simple design can be made by yourself if you follow the following steps.

- Take four metal rods, cut them so that they are the same length, 350 mm each.You will need to weld a square from the blanks.

- Take two rods and make a structure of them in the form of a large English Y. The length of the rods is 1.7 meters. It is necessary to ensure that the space between the horns is equal to the size of the sides.

- Weld the workpieces made in the last point to the square in the middle of the two sides.

- Make the sidewalls according to the same principle that was described in the first paragraph, only the height will depend on the desire of the master.

- Cut the sheet metal to the shape of the bottom and weld it on. If it is not there, then it is allowed to use rods, after welding which a lattice is obtained along the bottom.

- Weld the rods on the sides to prevent the wood from falling out.

The metal at the junction of the welds will need to be cleaned to remove irregularities and give the structure a more attractive look. After that, the product is covered with paint of the desired color, which will additionally protect against the negative effects of moisture and protect against corrosion.

If there are no rods at hand, but a profile pipe is enough, then the structure can be welded from this material.

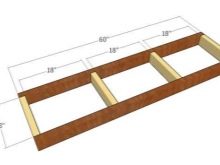

- First, they make blanks, which then just need to be welded together.

- 3 long pipes are cut, which will determine the length of the future firebox. Between them, the distance is calculated that is comfortable for the room in question, there should be 6 such blanks.

- For the sidewalls, 4 sections of the profile pipe are cut, they will determine the height of the structure.

- Now two long pipes and short ones are welded to make a base. Another long segment is welded in the middle and two short ones across it.

- From the inside, pipes are welded at the corners, which will form the sides, from above, the structure is completed by welding small pieces along the width of the firebox.

All joints are also well polished, and the product is covered with paint.

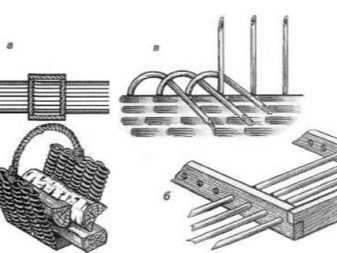

If you do not want to make a completely metal structure, then you can make a wicker firewood.

For work you will need:

- metal wire;

- willow twigs;

- wooden bars.

Before starting work, the masters are advised to treat the willow vine with an antiseptic composition, since this way you can extend its service life. The creation process is as follows.

- A square base is hammered together from four wooden blocks.

- Wooden bars are screwed in the corners with self-tapping screws. Between them, a wire is wound on both sides at a distance of 50 mm and bent upward, it will be a support for future weaving. Thus, the wire should be parallel to the timber at the corners.

- On two sides, in vertical wooden blanks located opposite each other, holes are drilled every 30 mm, where the willow is threaded and the sidewall is woven, passing through the wire, first from the left side, then from the right.

- From other sides, you can repeat the weaving process, just do not raise the sidewall to the same level with the previously created weaving.

- A handle is installed on top of the structure. The wire is first wound in several layers to the sides, then intertwined with each other and only after that it is covered with a vine.

The wooden structure is made according to a different principle.

- First, a frame is assembled, for which 2 boards of the same length are cut and 4 more of a slightly smaller size. In this case, you can take into account the size of the free area in the room. All of them are connected into a rectangle with self-tapping screws. The other two are screwed in the middle of the frame, since they will play the role of the bottom that holds the firewood.

- To create two sidewalls, cut four boards of the same length and 2 of the same size as the smaller part at the base. They are also interconnected with self-tapping screws, as a result, a rectangle is also obtained, but without one side, it is threaded into the base and screwed inside.

- Two sidewalls are interconnected by transverse boards, the width of which is selected at the request of the master.

A sufficient amount of firewood is stacked inside, this design is very easy to transfer, and there is no need for handles, since you can easily grab the sides of the firebox. As you can see, making roving with your own hands is a simple process, you just need to show patience and skill.

You can make a product with accessories, kits are sold in specialized markets. In any case, such a design is much cheaper than a ready-made one, and storing firewood in it is equally convenient, but there is an opportunity to save money.

You will learn how to make a portable mini-firebox with your own hands in the video below.

The comment was sent successfully.