Finishing the balcony with plastic panels

The balcony has long ceased to be used exclusively as a utility room for storing things and drying clothes. Today it is a full-fledged part of the living space of an apartment or a private house. Therefore, the owners treat its decoration as reverently and attentively as they do to the decoration of the rest of the apartment.

Repair is not only troublesome, but also costly. Budget finishing materials will help you to decorate the interior in a modern style and spend a minimum of money on it. They are presented in a wide range and have high performance characteristics. Plastic panels are a prime example.

Advantages and disadvantages

The choice of finishing for a balcony is a responsible business. Not every material can cope with changes in temperature and constant exposure to sunlight. Plastic panels have a number of undeniable advantages over their counterparts.

Among the advantages of this material:

- UV resistance (panels do not lose color intensity even after prolonged use).

- Durability (service life from 20 to 50 years).

- Strength.

- Resistant to sudden temperature changes.

- Waterproof.

- Resistant to insects and rodents.

- Good heat and sound insulation characteristics.

- Ease of installation and ease of maintenance.

- The ability to finish the balcony on your own without the involvement of a professional team.

- Wide range of.

- Environmental friendliness and safety for others.

- Affordable cost.

Plastic panels are equally often used to decorate the ceiling and walls, only in the first version, a material with a low weight is selected.

When buying material, you need to pay attention to several points:

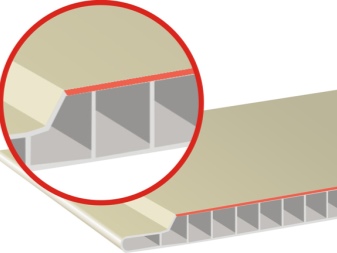

- Stiffening ribs on the inside of the panel add strength to the panel. The more often the ribs are located, the stronger and more reliable the finished surface will be.

- The inside and front of the panel should be painted evenly. The color should be even, without the presence of impurities or impurities. A sign of low quality is the grayish tint of the inner part.

- The edge of the plastic strip should be flat, smooth and free from jaggies. During installation, the panels must fit tightly to each other until a characteristic click appears. Only then will the connection be tight.

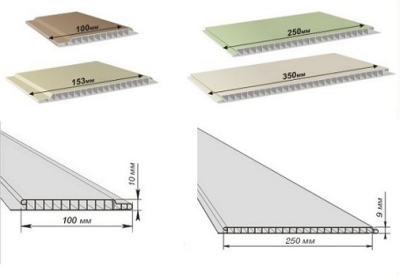

- Panels can be of different widths. Narrow ones are best suited for cladding an open balcony. Such material withstands temperature fluctuations better.

The undoubted advantages of plastic panels include their excellent compatibility with other types of material: plaster, wood, metal, glass, textiles, brick.

This greatly expands the possibilities of interior design.

Like any other material, plastic has a number of its own characteristics and disadvantages:

- When heated, the plastic gives off an unpleasant odor.

- The material is sensitive to strong mechanical stress (it can crack from a strong impact).

- Possibility of thermal deformation (for example, at very low temperatures).

Despite this, plastic panels remain one of the most demanded, budgetary and practical materials for interior and exterior decoration of the balcony.

For more information about finishing the balcony with PVC plastic panels, see the following video.

Varieties

Plastic panels are divided into several groups depending on size, thickness, appearance, texture, the presence of various additives and other characteristics.

Externally, PVC panels look like volumetric strips with internal stiffeners. They can be seamless (then the finished canvas looks solid and even) and seam (the coating has small gaps). The latter option is often used for vertical cladding of small spaces. Longitudinal seams visually "stretch" the room.

Size range

Standard panels are available in a wide range of sizes and thicknesses. For the decoration of the ceiling, a narrow lining is used, for the walls - plastic panels of different widths.

By type of coverage

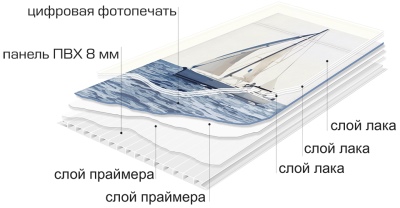

During thermal printing, the drawing is transferred to the panel using a special thermal film. The advantages of this method include the ability to apply patterns and colors of varying degrees of complexity and intensity. The protective varnish layer that covers the film gives the finished panel a glossy sheen.

The offset printing method is applied using typographic forms. Drawing can be very different, including photographic. The most popular is the imitation of natural stones: marble, granite, malachite and other minerals.

Another option for applying an ornament is laminated film. Various patterns are applied to it, including a pattern that repeats the texture of natural stone, textiles, and bamboo. Then this film is glued to the panel.

Preparation method

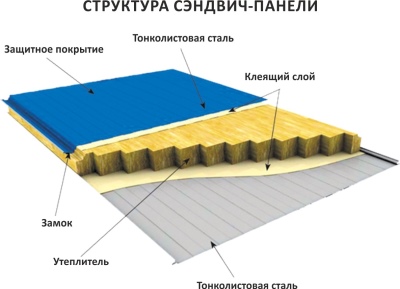

The first manufacturing option consists of pressing and stamping polyvinyl chloride. The second option is sandwich panels. This is a fairly new design option, but it has already become very popular. Such material consists of two layers of polyvinyl chloride and a layer of insulation. Usually, mineral wool or expanded polystyrene is used as an interlayer.

Such a panel can be one-sided (usually used to decorate walls or slopes) and two-sided (design partitions). The materials included in the composition of the sandwich panels make it possible not to use additional layers of vapor or waterproofing when decorating surfaces. The material is available in several thicknesses.

The disadvantage of such panels is their rather large overall dimensions (1.5 * 3 meters).

Appearance

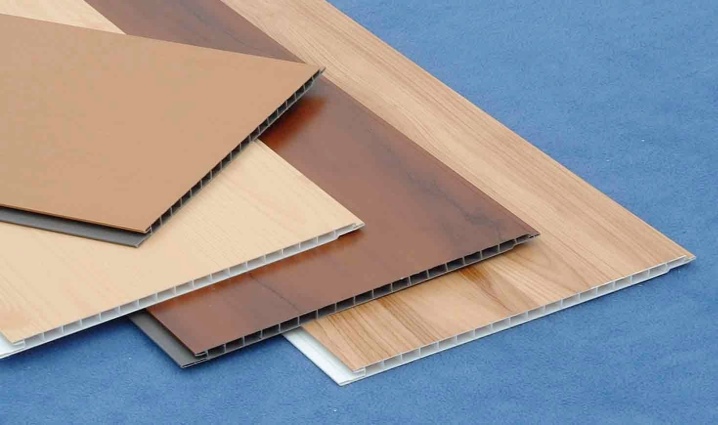

Plastic panels today are presented in a very wide range, so it will not be difficult to choose an option for finishing a balcony that is suitable in style, size and cost. Panels can be solid or patterned, smooth or textured.

Transparent panels are an original way to decorate your balcony in an unusual way, making it more open and light. Transparent plastic perfectly transmits sunlight and has all the operational and physical and mechanical characteristics of a conventional material. A balcony finished with transparent panels can be used as a home greenhouse, for example.

Required tools and materials

In the process of working with plastic panels, the following tools may be required:

- building level;

- drywall knife (great for cutting plastic);

- construction stapler;

- crosshead screwdriver;

- drill or screwdriver with magnetic attachment;

- hacksaw for metal.

Necessary materials:

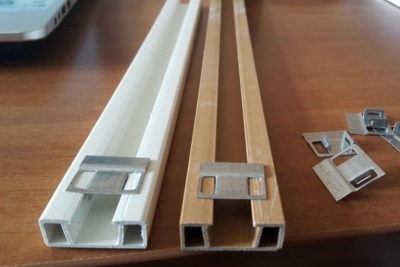

- wooden slats or metal profile for the manufacture of lathing;

- insulation;

- additional strips (starting, finishing, connecting strip, inner and outer corners made of plastic);

- straight panels for wall decoration;

- corner panels with two edges for finishing balcony corners and with three edges for decorating slopes.

To fasten the battens, panels and additional elements, you will need dowels 6 mm thick and 8 cm long, self-tapping screws, staples for a stapler, cleats, liquid nails, mounting foam (depending on the type of fastening chosen).

Calculation of materials

In order to correctly calculate the required amount of material, it is necessary to measure the perimeter of the room. The resulting value must be divided by the width of the selected panels and a few spare pieces must be added for trimming or scrap.

Preparatory work

Balcony cladding begins with the preparatory work stage. The final result largely depends on how carefully it is executed.

Preparatory work includes:

- removal of old coatings (paint, wallpaper, panels, plaster);

- checking all surfaces for cracks, potholes, chips, bulges;

- sealing cracks with cement-sand mortar, removing bulges with a perforator, protecting metal interior elements with an anti-corrosion coating;

- surface treatment with an antiseptic to prevent the appearance of fungus and mold (this procedure is performed 2-3 times in a row with an interval of about 4 hours).

If this is provided for by the project, then the balcony must be insulated and glazed. The surfaces to be treated must be covered with a waterproofing layer.

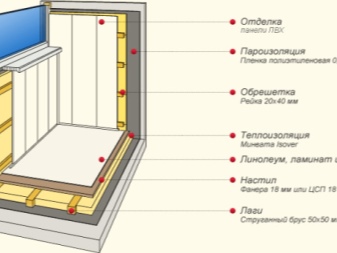

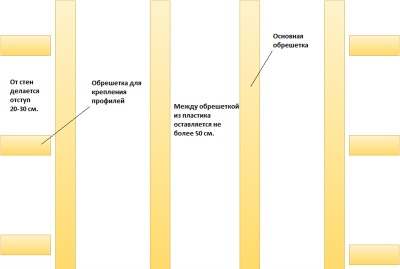

For cladding walls and ceilings with plastic panels, a wooden or metal crate is exposed. This allows you to create the necessary air gap between the plastic and the thermal insulation. Depending on the selected material, the lathing is exposed in a certain way. For vertically arranged panels - horizontal crate and vice versa.

Fastening methods

Plastic panels can be fixed to walls, ceilings and floors in different ways:

- The simplest and most short-lived option is installation on liquid nails. This method is used for relatively recently leveled ceilings and walls. The panels will last exactly as long as the glue dries, so its service life should be checked with the seller.

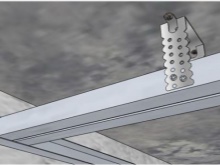

- The strongest and most reliable mounting method is mounting on a metal crate. Most often, a metal frame is used for ceiling covering, because there the base for plastic should be as reliable and strong as possible.

- Sometimes PVC strips are also used to create the lathing. This method is the least common, as it is rather difficult to execute.

- The most popular option today is a wooden crate. It will require a wooden rail 50 * 20 mm and dowel screws.

To fasten the panels to the crate, depending on its type, you will need wood / metal screws, staples or cleats.

How to sew with your own hands inside: step by step instructions

After the stage of preparatory work, you can proceed directly to the cladding with panels.

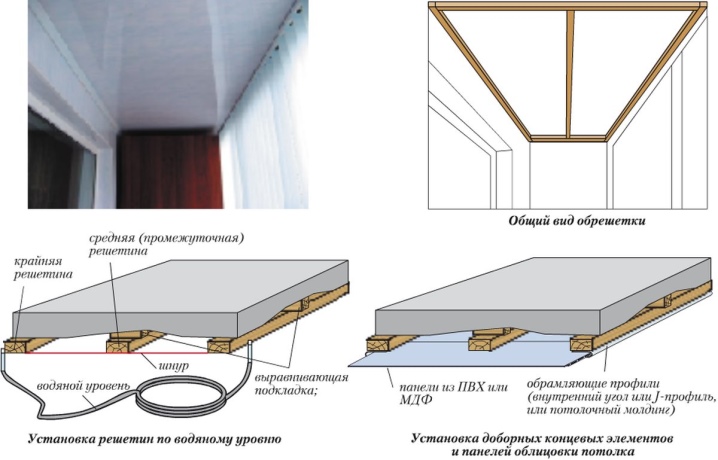

The best place to start is from the ceiling. The whole process of work includes several stages:

- The surface is marked. For this, the center of the ceiling is marked and a longitudinal line is drawn through it with the help of a level. Further, the marking is carried out on all sides of the ceiling, retreating from the edge of the wall by 5 cm.

- A galvanized profile is applied along the perimeter of the ceiling and holes up to 5 cm deep are drilled in the wall every 25-30 cm.

- Dowel screws are inserted into the holes obtained and the profile is fixed with a screwdriver.

- Then, depending on the size of the ceiling, 1-2 longitudinal profiles are installed.

- Starting strips of plastic panels are attached to the longitudinal profile.

- If the design project provides for the installation of lamps, then the wiring is pulled through at this stage.

- The first panel is inserted into the starter strip and fastened with self-tapping screws to the longitudinal profile and edging. Subsequent panels are inserted and fixed in the same way. The last panel is cut to size if necessary. The ceiling is ready!

The next step is to work with wall panels:

- Manufacturing of wooden lathing. At a distance of 10-15 cm from the level of the ceiling and floor, horizontal strips are set along the perimeter of the room. Then, every half a meter, vertical slats are installed.

- The starting plastic profile is attached.

- At the joints of the walls, external or internal plastic corners are installed

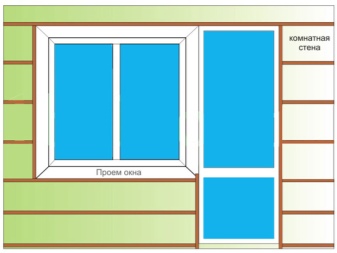

- Installation of plastic panels. The first strip is attached from one corner to another or from the corner to the door / window opening strictly vertically or horizontally. The slight slope at the beginning will only increase with each new panel. The panel is inserted into the starting strip until it clicks and is attached with self-tapping screws to the crate. Each next strip is laid very evenly and tightly pressed against the previous panel.

- The last strip is trimmed and inserted into the groove of the previous panel to achieve a tight seal.

The detailed process of finishing the balcony with plastic panels is in the next video.

Stages of cladding outside

The external facing of the balcony is a stage no less important than the interior decoration. To be sure of a high-quality and fast result, it is best to use the help of professional builders. But if this is not possible, then you can sheathe the balcony from the outside with your own hands:

- First, you need to remember that for outdoor decoration, a material is used that is designed specifically for this purpose. The width of such panels varies from 10 to 37.5 cm.

- Plastic cladding is considered one of the most practical and affordable ways to decorate a balcony outside. The panels are not afraid of water, tolerate temperature fluctuations well, have excellent decorative characteristics, are durable and do not require special maintenance.

- Work begins with the preparatory stage, cleaning the surface from old finishes and eliminating defects.

- The next step is to attach wooden or metal bars to the balcony railing as a lathing.

- Then the plastic corners, the starting profile are installed and the installation of the main material begins. Each panel is attached to the cladding vertically using self-tapping screws or a construction stapler.

It must be remembered that finishing the balcony from the outside (if we are not talking about the first floor of the house) is a process associated with risks and dangers. When working, it is necessary to strictly follow the safety rules. It is necessary to carry out installation work with an assistant.

The comment was sent successfully.