All about asbestos sheets

Now on the market of modern building and finishing materials, there is more than a wide range of products. And one of the most demanded and popular categories is asbestos sheets. At the moment, you can easily find out everything about such products, including their main performance characteristics, areas and features of application, as well as cost.

This material has been widely used in construction for a long time. Such record popularity is due, among other things, to refractoriness and thermal conductivity indicators.

Specifications

Taking into account the demand for asbestos sheets of different types, it is necessary to pay attention to the key performance indicators of this material, as well as the main advantages and equally significant disadvantages. First of all, it should be noted that we are talking about sheets made from a mixture that includes:

- asbestos;

- quartz sand;

- cement;

- water.

The wide scope of application of asbestos-cement slabs with a smooth surface and corrugated sheets is due to their main characteristics. The list of the most significant points includes the following.

- Dimensions and weight, which will be described in more detail below.

- Sheet thickness, which ranges from 5.2 to 12 mm. It is important to note that the wave slate has a standard thickness of 6 mm.

- Flexural strength, which is determined by the technology of production of the material. In this case, the point is that the indicated indicators for pressed and unpressed sheets differ significantly. They are 18 and 23 MPa, respectively. In the situation with wave materials, this value is 16-18 MPa.

- Impact strength - a parameter that also depends on the manufacturing method. For pressed sheets and made without applying a lot of force, indicators at the levels of 2 and 2.5 kJ / m2 are characteristic.

- Specific gravity of the material, determined by its density.

- Resistant to low temperatures. According to the standards, all described materials, regardless of their configuration, must withstand at least 25 freeze-thaw cycles. By the way, sheets with a flat surface benefit in this regard, since they are able to withstand up to 50 of the mentioned cycles.

- Moisture resistance... In accordance with current regulations, flat and wave asbestos-cement products must fully retain their basic qualities under direct and continuous exposure to moisture for at least 24 hours.

Analyzing the features of ADS, it is necessary to focus on their main competitive advantages.

- Increased mechanical strength... As proved by many years of practice, roof structures made of asbestos-cement sheets are capable of withstanding loads of up to 120 kg. In other words, an adult and rather weighty person can easily move along them. In addition, slate roofs are characterized by good resistance to wind gusts and adverse weather conditions.

- Maximum resistance to direct UV rays. It is known that slate is poorly warmed up even in the hottest weather, which in itself allows you to create a comfortable indoor climate.

- Long service life (up to 50 years) without compromising performance.

- Increased fire resistance. One of the unique characteristics of ADSL is its ability to withstand rather high temperatures for a long time. It is also important to note that slate is non-combustible and therefore does not support combustion.

- Ease of processing.

- Corrosion resistance.

- The minimum indicator of electrical conductivity, which in itself minimizes the risks of fires, as well as electric shock to a person.

- Good noise insulation properties... Of course, slate in this case is inferior to basalt cardboard and a number of other effective insulators, but it still demonstrates good performance.

- Resistance to aggressive environment, including alkalis and other chemical compounds.

- High maintainability... Replacement of damaged structural elements, regardless of their complexity, as a rule, does not cause any difficulties. All operations can be performed with minimal time, physical and financial costs.

- Minimal care... This means that there is no need to regularly perform specialized work.

This impressive list of clear advantages of the described material fully explains its prevalence. But, as you know, nothing is perfect, and therefore flat and wave slate also has certain disadvantages.

- Low resistance to chemical attack in the absence of antiseptic treatment... As practice shows, in such situations, moss very often sprouts on the slate, and other fungal formations are also formed.

- Quite a large weight of products compared to many other modern roofing materials. It is no secret that lifting slate sheets to a height requires considerable effort and time.

- Fragility that makes it difficult to transport, carry and the same lifting of products... In this case, all manipulations should be performed with utmost care and attention to prevent damage to the sheets.

- The presence of asbestos in the raw material formula, which poses a danger to human health and can cause serious illness if ingested.

It is worth noting that, Despite the highlighted shortcomings, this sheet material continues to enjoy a truly record-breaking popularity, especially among private developers. And the key role in this case is played by affordable cost, optimal price-quality ratio.

Views

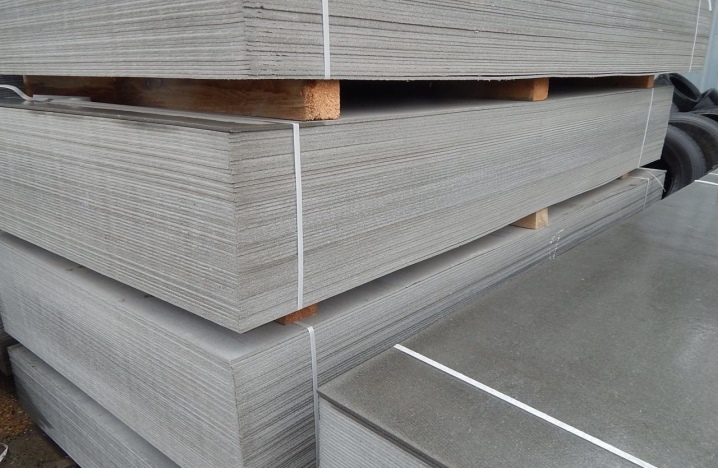

All manufactured cement-asbestos sheets can be divided into two broad categories: flat and wavy. It is worth noting that most people are familiar with the second type of this building material. Such - one might say classic - slate is produced in accordance with GOST 30340-95. These sheets, in turn, are divided into several varieties, each of which has its own differences in terms of key parameters and characteristics.

The release of flat sheet material is carried out taking into account the norms enshrined in GOST 18124-95. It is important to take into account that such sheets are also different. The main differences in this case are in the strength and density of the flat slate.

In the context of appearance, it should be noted that most often the described products are produced in gray without any additional coatings. However, color options can also be found on sale. Pigments are added during the production process at the stage of preparing the cement paste.

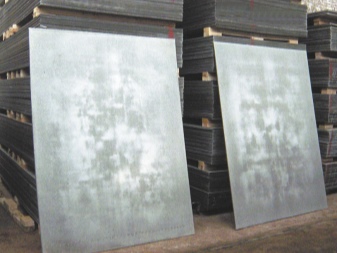

Flat

Such asbestos-cement sheets look like slabs, and their manufacturing technology provides for both the use of the pressing method and the production of material without force.... In this case, it will be visually very difficult to distinguish a pressed sheet from an unpressed one. It is worth noting that regardless of the specifics of production, the dimensions of the material are standardized.

These two types of raw materials have certain performance characteristics. Pressed sheets significantly surpass their "counterparts" in density and mechanical strength. Taking these parameters into account, such slabs will also have a higher specific gravity compared to unpressed flat slate.

The latter in this sense can be called a lightweight option.

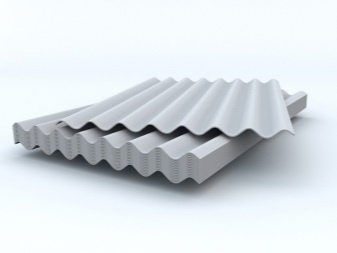

Wavy

Asbestos-cement sheet with a wavy profile is most often perceived as a material for the construction of a roof. For many decades, roofs of various structures have been assembled from such sheets: from residential buildings to industrial buildings. But it is worth noting that the material is often successfully used for the construction of fences of various configurations.

Slate samples of this category produced today differ from each other in size, as well as in the number of those same waves. So, as a roofing material, 6-, 7- and 8-wave sheets of different sizes are used. In addition, it is important to note that they can be:

- standard;

- average and central European;

- unified;

- reinforced.

Analyzing the features and key characteristics of these types of corrugated slate, it can be understood that the main difference between them lies in the shape of the profile.

The increased demand and popularity of these sheets are due, among other things, to their affordable cost. As a result, a real opportunity is provided for the construction of strong and durable roofing structures at relatively low financial costs. The mentioned reinforced models are one of the rational options for the construction of reliable industrial and agricultural buildings. In addition, they are successfully used for building envelopes.

Dimensions and weight

The dimensions of asbestos sheets with a smooth surface, that is, flat, are standardized. Depending on the version, different models may have the following parameters:

- length - 2500–3600 mm;

- width - 1200-1500 mm;

- thickness - 6–10 mm.

The dimensions of wave slate, like flat slate, are regulated by the current GOST and are:

- sheet length for all existing standard sizes - 1750 mm;

- width - 980 and 1130 mm;

- thickness, taking into account the shape of the profile - 5.8–7.5 mm;

- wave height - 40–54 mm.

It should be noted that in practice, in the production of sheet materials, a deviation from the above standards is allowed. In this case, all sheets that go on sale, regardless of their type and characteristics, must be marked. From these symbols, you can quickly determine the key parameters of the material. For example, if 3000x1500x10 is indicated on a sheet, then this means that its length, width and thickness are 3000, 1500 and 10 mm, respectively. On the material, 1.5 meters long, 1 wide and 0.01 meters thick, there will be an inscription 1500x1000x10.

Another important parameter is the weight of the sheets. It can be from 35 to 115 kg. So, the mass of wavy ACL is 35 kg, depending on the dimensions. At the same time, the specific weight (per 1 m2) reaches 17.9 kg.

These parameters are taken into account by workers both during the installation of new structures and during the dismantling of old ones.

Applications

As already noted, due to the optimal ratio of price and quality, as well as durability and other high performance indicators, the described sheet materials are now more than widespread. Due to their versatility, they are now almost universally used in construction.

The use of flat asbestos-cement slabs and corrugated slate allows you to effectively and at competitive financial costs solve a wide range of problems of varying complexity, namely:

- erection of roof structures of almost any complexity over residential, industrial and public buildings;

- the creation of fairly strong fences, including as part of industrial construction at various facilities;

- installation of protective and decorative cladding of various architectural elements in the form of loggias, balconies and other things;

- exterior wall decoration;

- use in tandem with heaters, including extrusion, for baths, stoves, boilers and facades;

- construction of pressure walls, as well as internal partitions;

- installation as window sill panels;

- screed formation;

- production of sandwich panels (outer walls);

- formwork construction.

We should also focus on the refractory properties of the described sheets: they are able to withstand high temperatures. It is the heat resistance that allows them to be used for facing furnaces, heating boilers, as well as chimney systems and air ducts. Another, no less important point is that flat materials are successfully used when arranging fixed formwork as part of pouring foundations. Such a wide and varied scope of application of sheets is primarily due to their strength and durability against the background of an affordable cost.

But despite all the above, the traditional area of application of slate is still the creation of roofing structures. It should be noted that high quality corrugated sheets guarantee, in addition to strength, an aesthetic appearance of the roof.

By the way, small flat samples also perform the functions of roofing material.

How to work with sheets?

Installation of the described material is a fairly simple process. This is true for both roofing and facade work. The latter are in many ways reminiscent of the creation of drywall structures. In this case, an L-shaped profile and joint materials are often used. Fastening wave and flat sheets, of course, has certain nuances. However, special attention should be paid to the rules for cutting and drilling asbestos material, taking into account its basic properties and characteristics.

Thin slate can be neatly broken according to preliminary markings. This will require:

- mark the break line;

- carry out along the marking with a nail or any well-sharpened cutter so that in the end a groove is obtained;

- put a flat rail or small bar under the sheet;

- Press evenly on the part to be separated.

A clear plus of this method is the complete absence of dust potentially dangerous to humans.

The second method involves using a special slate nail and performing the following actions:

- mark the ADSL;

- draw along the markup with a sharp object;

- make holes along the marked line using a nail with a step of 15–20 mm;

- as in the previous case, put a rail under the break line and break the sheet.

It is important to take into account that the result will directly depend on the number of holes punched.

In addition to the methods described, slate can simply be sawed with a hacksaw. In this case, the algorithm will include the following steps:

- markup;

- the location of the ADSL in such a way that its smaller part is in a cantilever position; this segment of the sheet will need to be supported with something to prevent fractures;

- cutting the material along the outlined lines.

As practice and experience of masters show, for these purposes, a hacksaw is best suited, which is used to work with foam concrete.

The fourth method is to cut asbestos-cement sheets with a grinder with a diamond or cutting disc installed on it on a stone. In the process of performing work, it is strongly recommended to water the cutting area with water. This is to reduce the amount of harmful dust that inevitably and in large quantities is generated when using this power tool. Similar measures should be taken when working with parquet and circular saws.

Very often, when erecting various structures from the building material under consideration, it becomes necessary to drill holes. In this case, the aforementioned fragility of ADSL will be the key point. Taking this feature into account, it is important to choose the right quality tool and method of work. For these purposes, you will need an electric drill and a good drill bit with a victorious bit. During the drilling process, certain rules will need to be followed.

- The diameter of the drill used should be slightly larger than the dimensions of the fasteners for which the holes are made.

- In the process of performing work, the slate sheet should rest tightly, preferably on a soft surface. Otherwise, the risk of damage to the material increases significantly, given its fragility.

- If it is required to make a hole with a large diameter, then it is allowed to use feathers, as well as victorious and diamond crowns.

- It is not recommended to punch large holes with slate nails.

- When drilling thick sheets, it is better to do several approaches, wetting the drill and the drilling area during breaks.

- Before starting drilling, it is necessary to make a markup and screw the place under the drill in order to prevent it from slipping, with a slate nail or any other tool.

- It is extremely undesirable to activate the hammer mode on the drill.

If you adhere to the listed recommendations, then you can quickly and easily make a neat hole of the required diameter in both flat and wavy slate.

Taking into account the peculiarities of the composition of the material, special attention must be paid to safety precautions when working with slate. By itself, ACL does not pose a threat to human health. Dust that accompanies the performance of certain operations (cutting, drilling) is toxic. Asbestos in this form, penetrating into the respiratory tract and settling in them, with a high probability, is capable of provoking the development of dangerous diseases. This is why it is highly recommended to keep the following important points in mind when working with asbestos materials.

- Work with the described material, especially its cutting and drilling, must be carried out in well-ventilated and ventilated rooms. It is important that the concentration of asbestos dust does not exceed 2 mg per m3.

- A prerequisite is the use of a respirator, which must first be carefully checked for integrity and operability.

- Also, the list of mandatory remedies includes glasses and overalls, which should as much as possible prevent the ingress of harmful dust on the skin.

- Asbestos-cement products should be stored in a separate and at the same time securely protected from excess moisture in a room.

In addition to all of the above, it is worth paying attention to the transportation of processed ACL, which must be carried out only in a sealed container. If this is not possible, the sheets should be watered with plenty of water to prevent the spread of dust.

The comment was sent successfully.