Composition and proportions of wood concrete

It is not difficult to make arbolite (wood concrete) with your own hands. The main convenience of this process is that it is carried out directly at the construction site. However, in no case should we forget that the independent production of wood concrete presupposes following a set of requirements. First of all, it is necessary to correctly determine what components the presented material consists of, their proportions, and the manufacturing recipe.

What it is?

Wood concrete is one of the varieties of lightweight concrete, the structure of which includes wood chips (shredded), high-quality cement, chemical additives and water. The need for chemical additives in the structure of wood concrete blocks is associated with the fact that in the organic component it is required to level the residual polysaccharide in order to increase the bond between crushed and cement, and also to further improve the characteristics of the finished building material, such as cellularity, forcing hardening, the ability to kill bacteria, etc. The economic effect of the use of this type of waste has been confirmed by leading companies in the production of wood concrete. A significant role in this issue is played by the rationalism of wood consumption.

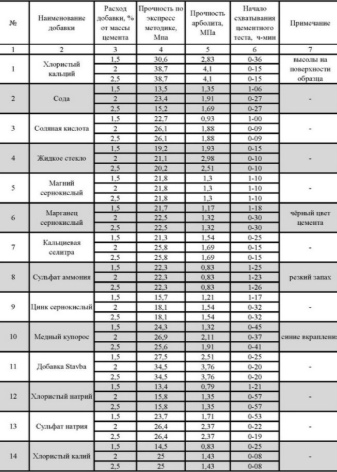

The main component for the production of wood concrete is waste wood from furniture and carpentry enterprises, from which crushed pieces of the required size are obtained. The technological characteristics of wood concrete depend on chemical additives. Along with calcium chloride, it can be water glass, aluminum sulfate, hydrated lime, they make it possible to improve arboblocks and add additional characteristics to them.

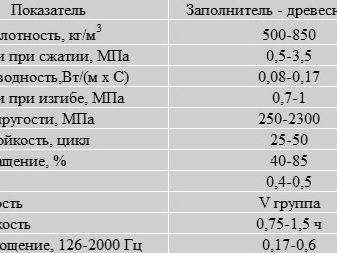

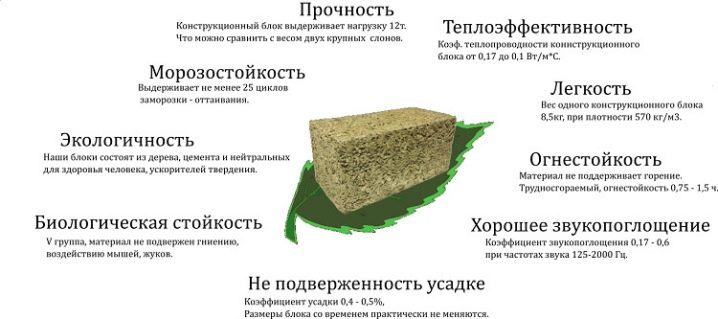

The technical parameters of wood concrete, in the structure of which there is an additive (chips from waste), are as follows.

- Average density. 400-850 kg / m3.

- Compression resistance. 0.5-1.0 MPa.

- Fracture resistance. 0.7-1.0 MPa.

- Thermal conductivity of wood concrete. 0.008-0.17 W / (m * s).

- Frost resistance. 25-50 cycles.

- Moisture absorption: 40-85%.

- Contraction. 0.4-0.5%.

- The degree of biostability. Group V.

- Refractoriness. 0.75-1.50 hours

- Sound absorption. 0.17-0.80 126-2000 Hz.

Composition

Like any concrete, the material contains a binder and filler - exclusively organic, as well as all kinds of additives. The origin and characteristics of the components have a great influence on the quality of the finished product. Organic additives give arbolite very significant sound and heat insulation characteristics.

In terms of strength, building material is practically no worse than concrete with similar density parameters. Such a combination of advantages is obtained only with the correct selection of raw materials.

Chemical additives

Cement has extremely low adhesion to wood due to the presence of various polysaccharides and sugars in it. Polysaccharides, finding themselves in an alkaline medium, such as a cement mixture, due to the decomposition process, become easily water-soluble sugars, which are considered a "concrete killer". All soluble sugars, once in an aqueous solution of cement, destroy the chemical hardening processes, the effect of which should be a complete cement stone.

The more polysaccharides in the water, the less the astringent is transformed into stone in the required period of time.The fruit of these actions will not be a monolithic, but a free-flowing cement stone. It does not have high strength and is unable to bind the wood additive into an integral material.

There is only one method to resist this - the washing out of sugars from the wood pulp; for this, the compositions of different reactants are used in heated water. These reactants include:

- sulphate aluminum;

- potassium and (or) sodium silicate (liquid glass);

- calcium chloride;

- slaked lime.

Organic ingredients

Several types of raw materials are used as a wood additive. Not every wood chip is suitable as a raw material - you should not associate wood concrete with sawdust concrete. The latest GOST clearly establishes the dimensions and shape of inclusions mixed into wood concrete.

- Crushed wood is made by crushing illiquid wood - knots, slabs, tops, etc. To create wood concrete, crushed material is used: length - 15-20 millimeters - no more than 40 millimeters, width - 10 millimeters and thickness 2-3 millimeters. On an industrial scale, grinding is carried out by specialized units. Practice shows that in order to obtain optimal quality in production, crushed crushed wood concrete should have a configuration of needles and be smaller in its parameters: the length is no more than 25 millimeters, the width is 5-10 millimeters, and the thickness is 3-5 millimeters.

The bottom line is that the wood absorbs moisture unevenly across and along the fibers, and the above parameters balance this difference.

- Not every tree is suitable for shredding: you can use pine, Christmas tree, aspen, beech, birch, but larch wood is not suitable. Before use, wood must be disinfected with antiseptics to prevent the formation of fungus or mold.

- Broken bark and Christmas tree needles can also be used. But their percentage is lower: the bark can be no more than 10% of the weight of the product, and the Christmas tree needles - no more than 5%.

- Rice straw, lignified cannabis and flax stems, and lignified cotton stalks also serve as raw materials. They are crushed: the length is no more than 40 millimeters, the width is 2-5 millimeters. Strips (waste from cleaning fibrous material) and hemp, if they get into the mixture, should not exceed 5% by weight. GOST 19222-84 regulates the parameters of fractions obtained in the process of crushing various types of raw materials. And even if deviations are possible in the ratio of the components, it is prohibited to deviate from the standards of raw materials.

Flax contains a significant accumulation of sugars, which, entering into chemical interaction with cement, destroy it. To avoid this, the lignified parts of the flax stem are initially soaked in slaked lime for 1-2 days or kept outside for 3-4 months.

Inorganic substances

The following ingredients are cementitious in arbolite:

- Portland cement is a classic material, it is especially popular;

- Portland cement with mineral auxiliary elements - as a rule, this method increases the frost resistance of blocks;

- sulfate-resistant cement, apart from pozzolanic, guarantees resistance to aggressive chemicals;

- in accordance with the conditions of GOST, only a material of a brand that meets the following conditions can be used: not less than 300 (this applies to heat-insulating wood concrete) or not less than 400 (for structural).

Water

GOST regulates the indicator of water purity, but in fact they use different ones - from the central water supply system, wells, wells. The water temperature is considered to be decisive for the proper quality of wood concrete. It is mixed into the mixture together with auxiliary components.

In order for the mortar hardening rate to be optimal, heated water of at least +15 C is required. Already around +7 +8 C, the cement hardening rate is significantly reduced.

Mixing proportions

Let's analyze the ratio of the mortar additionally per 1 m3 of wood concrete with our own hands.For the option, calcium chloride plus aluminum sulfate per 1 cu. m of ready-made mortar: 500 kilograms of Portland cement M400, the same amount by weight or slightly more chips, 6.5 kilograms of each type of chemical, about 300 liters of water. If you are going to use lime with water glass, the proportion will be 9 plus 2.5 kilograms, all other things being equal.

For clarity, it is not necessary to use tables, you can simply count on 1 cubic meter. m these ratios for mixing in buckets of 10 liters:

- cement - 80;

- shredded - 160;

- fillers - calcium and chlorine a little more than half a bucket;

- aluminum oxide - the third part.

Mixing all this, we get a little more 1m3 of raw wood chips, and after tamping and setting it in the formwork - 1m3 of wood concrete of grade 25.

Correction of the composition

If you use a different grade of cement, then the ratio is calculated using the coefficient: for M300 it will be 1.05, for M500 - 0.96, for M600 - 0.93. The crushing ratio is given for completely dry raw materials. Basically such a rarity. In this regard, its amount must be adjusted in accordance with the degree of humidity - add a small amount. To calculate the additional volume, we multiply the above mass by a coefficient calculated as the percentage of crushed moisture divided by 100%.

Recipe

A lot of recipes for making monolithic wood concrete with their own hands at home are practiced. In some recipes, timber is prepared and processed, in others, a chemical element is mixed. According to one of the methods, the crushed material is soaked in lime (80 kilograms of lime per 1 m3 of wood), then squeezed out. Then sprinkle on top with quicklime powdered lime (80 kilograms), stir, level, dry and add to the composition. Thus, they get rid of woody sucrose, which affects the quality of monolithic wood concrete.

Fiddling with crushed shredders, and even more so in such volumes, is a rather time-consuming task that requires space. In this regard, the use of calcium chloride or aluminum sulphate will become a quick way of making wood concrete. And then the crushed material can be left untreated, but it will be better if you let it sit outside, in the rain and sun for a couple of months. If possible, soak it in water, and dry it on the eve of preparing the solution. Soaking and curing is just a routine preparation of the wood pulp, allowing for a little sugar removal.

At the stage of preparing a mixture of wood concrete, calcium chloride or aluminum sulphate is mixed in - 2-5% of the weight of the cement. So what is the ratio of chemical additives for wood concrete 2% or 5%? It depends on the grade and on the properties of the cement. The composition of one grade (for example, M500) only from different manufacturers may differ in quality characteristics. In this regard, it is advised to perform a test batch.

If, when adding calcium chloride, 5% of the total mass of the cementitious substance, a white salt coating appears on the hardened material (efflorescence, efflorescence), then the proportion of the content of the chemical element must be reduced. The exact ratio of the chemical component for monolithic wood concrete does not exist. It constantly needs to be installed independently in accordance with the quality of the cement and crushed used.

Someone does not want to mess with the selection of the ratio of calcium chloride. And, so that efflorescence does not appear, sodium silicate is mixed into the mixture. For example, 2% calcium chloride and 3% sodium silicate by weight of cement. But sodium silicate is quite expensive, in this regard, it is cheaper for most to carry out a couple of test batches and find out the ratio of calcium chloride. To give arbolite various additional properties, the use of slaked and quicklime, liquid glass, aluminum sulfate, calcium is practiced.

For the pros and cons of wood concrete, see the next video.

The comment was sent successfully.