Arbolite house: pros, cons and construction features

Today, a person who is going to build his own house has to make a very difficult choice. The fact is that a vast variety of the most modern and already well-known building materials can put a layman in a hopeless position. Even highly professional builders now and then hold discussions among themselves on the choice of the key building material for the construction of the walls of any structure.

In this article, we will talk about another building material called arbolite (wood concrete). We will not admonish the mandatory use of this building material in the process of performing construction work, we will simply talk about its inherent advantages and typical disadvantages.

Advantages and disadvantages

Due to its structure and features, arbolit (wood concrete) is endowed with both a number of positive qualities and some flaws.

Positive properties make it possible for blocks of wood concrete to compete with classical building materials, and disadvantages make it unacceptable to use in specific situations (multi-storey construction, high humidity).

In general, there can be no building material consisting of some advantages, otherwise it would be used everywhere, and the rest were undeservedly forgotten. The advantages of wood concrete as a building material are obvious.

So, a block made of wood concrete has many advantages.

- Thermal conductivity wood concrete is approximately the same coefficient for light cellular (porous) concrete and makes it possible not to produce additional insulation. However, this similarity can also become a minus, since in some areas the presented material is more expensive in comparison with the named concretes.

- When following the manufacturing technology of wood-concrete the block is environmentally friendly, which is especially important for people who are concerned about the environmental cleanliness of building materials and the state of the environmental situation.

- Material has good sound absorption, which provides the utmost protection of all inhabitants of the house from extraneous noise from the street and adjacent premises.

- On the positive side can be attributed to the high vapor permeability, which makes it possible for the walls to "breathe", but the advantage immediately becomes a disadvantage as soon as the conversation turns to areas with a consistently high saturation of the atmosphere with moisture and cool climatic conditions. Everything is explained by the fact that in the presented version, the thermal efficiency of a building material is capable of dramatically changing for the worse.

- Due to low volumetric weight lung blocks, and when working with them, the use of an order of magnitude less physical effort is required compared to denser building materials, and the need for lifting equipment is significantly reduced.

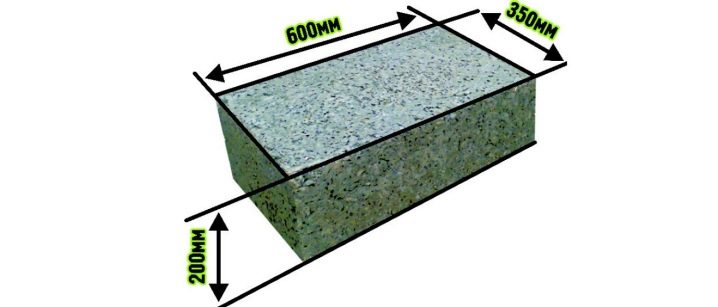

- Dimensions (edit) wood concrete block makes it possible to build structures at a much higher speed than when using the same brick.

- With wood concrete very easy to work, it can be sawed without any problems with any sawing tool. In addition, you can drive nails into it and screw in self-tapping screws.

- Due to the structure of the material and its very high flexural strength, it is possible not to reinforce the walls and not to install reinforced belts, which further reduces resource consumption and operating time. There is a similar positive point only in low-rise construction.

- Wood concrete block not flammabletherefore, there is no need to worry about its fire resistance.

The disadvantages of wood concrete blocks include some nuances.

- The ability of the manufacturer to profit from the cement used in the production of the blocks. In this case, the building material sharply loses its strength, thus, this minus also eliminates some of the previously presented advantages.

- Similarly, a disadvantage that can nullify a number of advantages is the permissibility of the manufacturer changing the fraction of wood particles in the structure. From this it follows that the release of products with a too coarse fraction of chips is likely, or, on the contrary, sawdust may constitute the main share of the wood component. Both options have a great impact on the quality characteristics of the finished block and, therefore, the structure built from it.

- Wood concrete due to wood in its structure is able to absorb water in significant volumes, because of this, it is required to pay close attention to protecting structures made of wood concrete from water penetration.

- Another drawback is the frequent errors in the geometry of wood-concrete blocks, they, as a rule, are not very strong, but they can lead to an over-consumption of masonry cement mortar. And it increases the thermal conductivity of the rebuilt wall more, which is also difficult to call an advantage.

Having examined all the advantages and disadvantages of wood-concrete blocks, one can draw the proper conclusions.

Wood concrete is an environmentally friendly material from which you can build an energy efficient house very quickly and thoroughly.

Building material should be used with caution for buildings with a high level of humidity of air masses inside.

Before purchasing, it is imperative to check the material and make sure of its quality characteristics. It is necessary to assess the size and intertwining of the wood particles in the structure, to check the absence of excessive formation of frozen cement mortar or loosely coupled component components of the products.

Design

In the process of creating a project, the composition and characteristics of the soil are established in order to calculate the characteristics of the foundation in accordance with this information. Then the shape of the house, the thickness of the walls, the presence or absence of thermal insulation, the placement of windows and doors, as well as other necessary characteristics are established. In addition, in the process of creating a project, the amount and type of building material is established.

For example, on the outskirts of the city of Sochi, a wall thickness of 20 centimeters makes it possible to do without thermal insulation, while in the Omsk zone the smallest wall thickness, which makes it possible to do without the use of thermal insulation, is 50 centimeters.

A well-designed project will save you from unnecessary consumption of materials and the ability to rebuild some areas or details during the construction of the house.

Note: all standard house designs ranging from 100 m² up to 150 sq. m will be adapted for the area of construction work (soils and local climatic conditions of the area).

Projects of houses made of wood concrete with an area of 100 to 150 sq. m can be one-story or two-story and have an attic, a garage and even a basement or basement in their structure.

Construction technology

The house can be built in two ways.

- Construction of wood-concrete blocks... In this situation, ready-made wood-concrete blocks are used industrially. Often a decision is made to make wood concrete with your own hands. Before starting work, you need to make sure that the blocks have reached the quality required for work.

- Monolithic construction from wood concrete... The application of this practice provides for the creation of a non-removable formwork with further pouring of an arbolite solution into it. To build a house from monolithic wood concrete, it is necessary to study the method of organizing monolithic walls. Other phases will be similar to block construction.

Preparation of the mixture

In the manufacture of wood concrete there are some tricks, without knowing which you cannot get the proper quality. Actually, here is basically the reason for the suspicious attitude of individual builders to this material.

At first glance, everything is clear - mix sawdust with cement and water. Only soon it turns out that what has been received does not want to harden, and when it has hardened, it peels off and cracks. Therefore, it is concluded that all the talk about the advantages of wood concrete is not worth the spent sawdust.

In reality, everything is not so primitive. There are different types of sugars in tree cells (hemicellulose, glucose, sucrose, and others). The listed are water-soluble elements that negatively affect the cement component of the material. They delay and sometimes completely interrupt the hardening, adversely affect the composition of the cement.

Fortunately for us, it is possible to fight this.

Much it is easier to let the wood raw material lie in the open air for two years... During this period, all compounds undesirable for cement are washed out, turn into substances that cannot be dissolved, or disintegrate.

But since such a long process is not possible every time, various ingredients are mixed into wood concrete to block sugars. Of them for the production of wood concrete with your own hands, a combination of slaked lime with water glass or calcium chloride and aluminum sulfate will do (aluminum sulfate).

The first way is more economical. In addition, some experts believe it to be the most faithful and less whimsical to the quality of the source material. The second attracts with a significant acceleration of the hardening of the solution.

Foundation

Due to the small mass, arbolite walls exert much less pressure on the soil than brick, concrete or stone structures, therefore, for such houses, pile screw, shallow tape, or combined foundations are used. This makes it possible to significantly reduce the price and labor costs of the work, when compared with the construction of the foundation for concrete or brick houses.

When constructing a foundation, close attention must be paid to protecting the building from water and thermal insulation, since in winter the insulated base has a much less effect on the temperature of the floors. For insulation from moisture, roofing material or roofing material is used, and for thermal insulation, foam plastic.

If you intend to create an insulated or warm floor, then there is no need to insulate the foundation.

Walling

Due to the fact that cement is used as a connecting element when creating wood-concrete blocks, different cement-based mixtures are used for laying arboblocks. You can use both a classic mortar in a 1: 3 ratio of cement and sand, as well as any glue or masonry compounds that are intended for blocks based on cement. Timber blocks can be sawed effortlessly with a simple hand saw, as well as an electric or chainsaw, therefore, on-site installation is not a problem.

As in the construction of houses from building stone, every 3rd or 4th row is fixed by means of reinforcement laid out on all arboblocks under a layer of masonry mixture or glue.

Due to the good strength of wood-concrete blocks, the installation of windows and door panels does not cause problems - they are fixed by means of anchor bolts.

The construction of the walls is started from the cornersby using a level, plumb line and a cord that is pulled between the last blocks, this makes it possible to lay other blocks along a precise line.In this, the laying of arboblocks does not differ at all from the laying of bricks, cinder blocks, foam blocks or gas silicate blocks. The masonry mixture must have the correct consistency so that the wood-concrete block displaces the excess mortar with its own mass. Walls must be erected at an air temperature of more than + 10 ° C... Before laying, wood-concrete blocks do not need to be soaked or soaked.

Manufacturers often bring to the client wet wood-concrete blocks that have not accumulated the required strength characteristics. Walls should not be built from such blocks, since the lower rows will be crushed by the upper ones, and the configuration of the wall will be upset. If damp blocks have been delivered, then it is necessary to lay them aside and allow them to rest for 15-20 days, after which they are absolutely ready for laying.

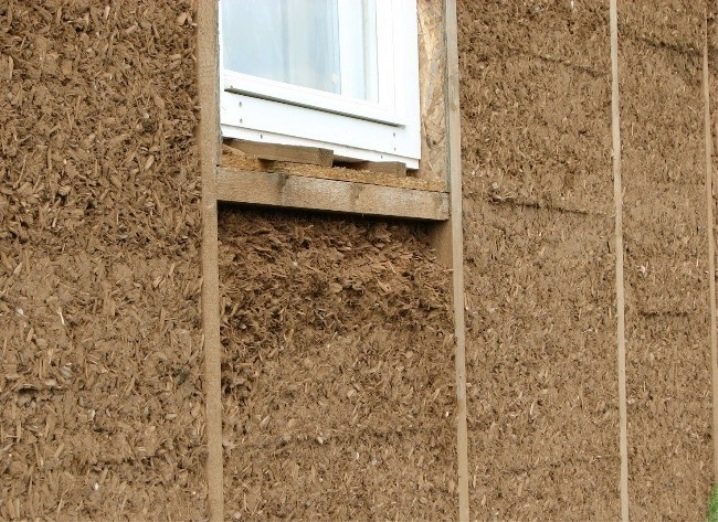

In parallel with block masonry, two methods of pouring load-bearing walls made of wood concrete with your own hands are practiced.

1. Rammed technology of pouring wood concrete, without frame

A string is pulled along the axis of the base of the house. Guided by it, formwork panels are installed.

The mortar is mixed, poured into the permanent formwork in layers of 20 centimeters and compacted, the mortar is added until it fills the formwork box to the very top. The packing is covered with cellophane and left to harden.

The next day, it is checked how well the mortar has gained strength, the formwork is dismantled, installed in another place, or raised to the next row. The formwork is again filled with the mixture and the mortar is compacted. This continues until the wall is ready.

2. Frame method of pouring wood concrete

A skeleton of future walls is made from a bar of 50x60 or 50x70 mm, the frame racks are aligned along the cord to form the outer and inner planes of the walls.

After that, the resulting frame is filled with wood concrete similar to the first option, moving the formwork along the frame bars.

Such a casting method is more expensive, but provides the highest accuracy, and is more convenient, since you do not need to control how the formwork is correctly positioned every time. We simply move the formwork along the vertical bars of the frame, as if along the guides.

Note: if you do not want to mess with it yourself, there is a ready-made house set of wood concrete panels on sale.

Warming

There are now many ways to build the walls of an individual house made of wood concrete. In warm regions, an arbolite wall can be built 30 centimeters without additional thermal insulation. In cold regions, an outer wall of 30, and sometimes even 40 cm, will not be effective enough to save heat. With the aim of, in order to prevent the structure from freezing, and to protect housing from possible heat loss, it is required to cover it with a layer of thermal insulation from the street.

Thermal insulation of walls made of wood concrete with expanded polystyrene

Polyfoam must be used exclusively for thermal insulation of the wood concrete house from the outside. In this case, it will be necessary to improve the ventilation system of air masses in the house, since the use of foam will lead to a decrease in the vapor permeability of the walls. The slabs are fixed to the facade by means of glue and, in addition, they are fastened with disc dowels, the gaps between the slabs must be well foamed to eliminate temperature bridges.

Thermal insulation of wood-concrete walls with mineral wool

Manufacturers of stone wool advise to use a layer of insulation of at least 10 centimeters for thermal insulation of the facade. It is better to lay slabs of mineral wool in two layers to exclude cold bridges in the structure.

In order not to miss in the selection of the thickness of thermal insulation, use the insulation calculator and do not forget to close the fiber insulation with a vapor barrier film.

Thermal insulation of wood concrete with sawdust and cellulose insulation (ecowool)

The presented materials refer to natural insulation materials consisting of cellulose.Sawdust and ecowool are filled in during the construction of walls between the load-bearing wall and the finishing brickwork. In the role of thermal insulation inside the walls, it is allowed to use expanded clay, polyurethane foam or expanded polystyrene boards.

Roof

On walls made of wood concrete, it is allowed to mount a rafter system of any design. Mauerlat can be made from a bar of 15x15 centimeters, rafters from a board of 50x200 mm, racks from a bar of 150x200 mm, a bed from a bar of 200x200 mm. The choice of roofing materials is also not regulated.

Experts also recommend using bituminous (soft, flexible) shingles for roofing. They explain their own choice by the fact that flexible shingles are able to perceive small swaying of wood-concrete walls without significant defects.

The fundamental aspect in the construction of the roof will be the fulfillment of the rule - the removal of the roof by 300-500 millimeters from the wall, which will make it possible to protect it from direct penetration of thawed and rainwater.

Finishing

The shrinkage of a timber concrete structure is only 0.4%. This makes it possible to start facing work immediately after the completion of construction.

Due to the strong moisture absorption of wood concrete (from 40 to 80%), walls must be protected from high humidity. This is also required by the unattractive appearance of wood-concrete walls.

For external wall cladding, it is possible to use any building material: siding, lining, brick etc. In most cases plaster is applied... If you will be plastering, then when choosing, you must not forget that the vapor permeability of the material used must be similar to wood concrete. To sheathe with clapboard or siding, it is required to carry out a thorough waterproofing and airing of the wall.

Note: a new type of material has appeared on the construction market - wood concrete with decorative trim. It makes it possible to do without facing the walls of the house from wood concrete from the outside.

A house made of wood concrete does not need internal wall cladding. The most important condition is that the humidity level in the used house is not higher than 75%. In another case, in particular, for a bath, it is necessary to take into account the additional vapor barrier of the walls.

Reviews

On Internet forums dedicated to the construction of houses from all kinds of building materials, you can see reviews about wood-concrete buildings. Some of them raise construction issues, miscalculations and hidden problems, the second part - residents touch on the experience of living in such houses.

But there is another type of reviews, they are not about buildings made of wood concrete, but they represent certain properties of the building material itself.

Those who build a house from wood concrete with their own hands talk about the accessibility and ease of working with this material, since it is much more comfortable and easier to use than any other types of blocks based on cement. Wood concrete blocks are very light, therefore, their laying does not generate such fatigue as working with building stone, gas and foam concrete.

The owners of arbolite houses claim a rather low level of heat loss, therefore, heating costs are much less than in stone or brick houses without thermal insulation.

Arbolite has good sound-absorbing properties, therefore, when the windows are closed, extraneous sounds do not get into the house from the street. In these houses, it is constantly moderately dry, since the blocks absorb excess moisture, give them outside or return to the room as the humidity decreases.

For the pros and cons of wood concrete, see the video below.

The comment was sent successfully.