Arbolite blocks: description, pros and cons, choice

The construction of residential buildings from wood concrete blocks is a modern approach to low-rise construction and is becoming more and more popular. The material compares favorably with brick and concrete and bypasses them in many performance indicators.

What it is?

Arbolite is a type of lightweight concrete and began to be used in construction about 60 years ago. In the Soviet Union there were more than 100 enterprises specializing in the production of this high-quality and durable building material. Then the demand for wood concrete decreased slightly, and until recently it was not so often used in construction.

Taking into account the latest trends and the increased demand for high-quality, warm and pre-fabricated housing, the wood concrete blocks have been remembered again, and today the material is rightfully considered one of the main types of building materials used in low-rise construction.

In order to understand why the material has so many fans, it is worth referring to its composition, from which it can be seen that wood chips occupy almost 90% of the total volume. For the manufacture of blocks, only selected and clean raw materials are taken: without twigs, leaves and other waste associated with woodworking... The remaining 10% are high quality cement, chemical additives and bonding compounds.

Externally, wood concrete is represented by square volumetric blocks equipped with a special shell consisting of a binder. The structure of the material is quite porous, which contributes to normal air exchange in the room and maintains an optimal level of humidity. In terms of its operational characteristics, arbolite is as close as possible to commercial wood and in many respects it surpasses brick and reinforced concrete.

The scope of application of wood concrete blocks is quite extensive.

The material is actively used in the construction of residential buildings and industrial structures. In buildings with a height of no more than 7 meters, internal and external self-supporting structures are erected from it, and also used for the construction of curtain external walls.

According to existing standards, wood concrete blocks can be safely used for the construction of buildings no higher than two floors. The material is used for the manufacture of wall panels and roof ceilings, as well as noise and heat insulation structures in the construction of private houses and summer cottages.

As you can see from the description, wood concrete can be safely called a universal building material, which, along with its high strength and wide consumer availability, makes it a truly popular material.

How is it done?

Arbolite blocks have very high performance characteristics, which is due to carefully selected raw materials for their manufacture. For example, wood chips, which are the main component of blocks, have a clear recommended dimensions, which should not exceed 40x10x5 mm.

In general, the choice of filler is determined by the region of manufacture of the material. In the northern regions, for example, as well as in the middle lane, where there is no problem in the lack of woodworking waste, mainly spruce, pine and fir shavings, as well as poplar, beech, birch and aspen chips are used.In the southern regions, hemp fire, rice straw and cotton stalk are used as the main raw materials.

As for the additives and fillers, to reduce the thermal conductivity of the material, components that increase its porosity are added to the composition, and bactericides and insecticides are added to protect the chips from decay.

Of the chemicals present in the composition of wood concrete, calcium chloride, sulphate alumina and limestone should be noted. Due to the presence of these components in the raw material, it was possible to achieve a noticeable decrease in the water permeability and thermal conductivity of the material. Cement for the production of wood concrete is also taken quite high quality.

For example, for the production of structural blocks, grade 500 is used, less often - 400, while for heat-insulating wood concrete, the cheaper version of the M300 is often used.

A prerequisite for the manufacture of blocks, which determines their technical characteristics in the future, is fast forming. The procedure is performed within the first 15 minutes after kneading and is carried out on special machines or manually... The mass is formed into blocks using vibration technology, which ensures high density and durability of the future product.

Compaction of raw materials into molds is carried out in several stages with the alternating formation of three layers. The optimal temperature for drying finished blocks is considered to be 30-40 degrees.... Under such conditions, the material will be ready in a day. If the air temperature does not exceed 20 degrees, then the complete solidification of the composition will take from 3 to 5 days.

When external temperatures drop below 5 degrees, the hardening of the concrete mixture stops.

The manufacture of wood concrete blocks at specialized enterprises is strictly regulated, and the composition is determined by the corresponding GOST. In the factory production method, the deviation in proportions is considered minimal and is usually no more than 2-5%.

Another important indicator that subsequently affects the operational properties of the material is the humidity and temperature of the working solution. The optimum humidity is considered to be less than 25%., as well as the temperature, which should not be lower than 15 degrees.

Only strict adherence to the formulation of the solution, as well as strict adherence to the technology of manufacturing wood concrete blocks, can guarantee high working qualities of the material and its ability to serve for many years.

Specifications

The main technical indicator of wood concrete is its thermal conductivity, as well as strength, frost resistance and sound insulation.

- Thermal conductivity the wood concrete is quite low and amounts to about 0.07-0.18 W / (m * C). This allows the outer wall of the building, erected from blocks, to retain heat in the same amount as a brickwork with a thickness of one meter is capable of doing.

- Strength wood concrete block is also quite high and varies depending on the composition in the range of 21-45 kgf / cm². Foam and aerated concrete, also quite often used in low-rise construction, have about the same strength indicator. For example, grade M25, corresponding to classes B1.5 and B2, has a compressive strength equal to 21-27 kgf / cm², while for M50 it reaches 45 kgf / cm². Thanks to this, the blocks do not crack and tolerate transportation and storage well.

- Arbolite is characterized by increased frost resistance and is able to withstand from 25 to 50 freeze-thaw cycles without losing its operational properties. This allows houses built from wood concrete blocks to stand in cold climates for 50 years or more. In warm areas, the lifespan of the material increases by about half to about 75 years.

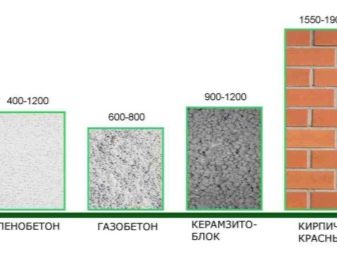

- Sound insulation coefficient is also an important performance indicator of the material and determines its use as a soundproofing shield.Sound insulation of blocks is in the range from 0.17 to 0.6 units, which is about 4 times more than similar indicators of bricks. To ensure noise absorption, material with a density of at least 500 kg / m³ is used, while for the construction of walls, wood concrete is used with an indicator of 550 to 850 kg / m³.

- An equally important technical characteristic of the material is its the weight... According to this criterion, wood concrete also surpasses a number of other building materials, which makes it more in demand. For example, the weight of one cubic meter of masonry made of wood concrete blocks is about three times less than the same volume of silicate bricks and one and a half times less than the same volume of expanded clay concrete.

- Incombustibility is also an important performance characteristic. Despite the high content of wood chips in the material, the wood concrete does not burn itself and practically does not support combustion. According to the regulations of GOST 12.1.0044-89, wood concrete belongs to the group of low-flammable (G1), hardly flammable (B1) and low-smoke (D1) materials.

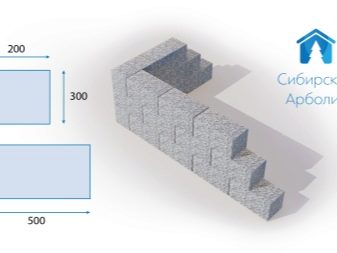

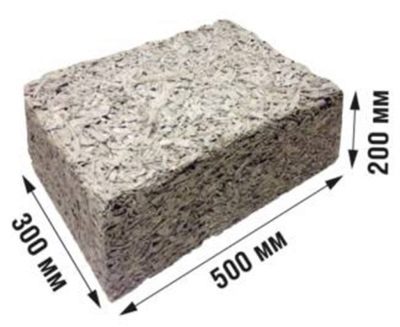

Arbolite blocks for the construction of external walls are usually produced in dimensions of 300x250x500 and 500x300x200 mm, and blocks for the construction of internal partitions are produced in dimensions of 200x250x500 mm.

pros

The high demand for wood concrete block is due to a number of indisputable advantages of this building material.

- The complete environmental safety of wood concrete is due to the absence of harmful impurities and poisonous additives in its composition. The material mainly consists of natural components, and the chemical reagents present in small amounts are completely harmless to humans and do not emit toxic substances into the environment.

- The incombustibility of the material is due to the appropriate additives, which several times increases the fire safety of housing built from wood concrete.

- The light weight of wood concrete greatly lightens the structure and reduces the load on the foundation. In addition, the universal dimensions of the blocks make them very convenient for construction and transportation.

- Low thermal conductivity and high heat-saving properties of the material allow you to save on insulating materials and help maintain a favorable microclimate in the room. In addition, wood concrete is well ventilated, which is why the walls of the building are able to breathe.

- The material is an excellent sound insulator and reliably protects the room from the penetration of extraneous noise from the street or adjacent spaces.

- The ability to drive a nail into an arbolite wall or screw in a self-tapping screw also distinguishes the material from other construction analogues.

- Due to the porous structure and high elasticity, wood concrete blocks are easily cut and divided into parts. At the same time, the material does not crack, crumble or crumble.

- Arbolite is not interesting for rodents and insects, and is also not a favorable environment for the appearance of fungus and the formation of mold.

- The surface of the blocks has high adhesion properties and does not need additional measures to improve the adhesion between the decorative coating and the material of the wall construction.

- Buildings made of wood concrete shrink quickly, and the maximum shrinkage is only 0.4%. This quality makes it possible to carry out interior decoration almost immediately after the walls are erected.

Minuses

However, along with the obvious advantages, the arbolite still has disadvantages. First, there is a high probability of block counterfeiting. Unscrupulous manufacturers use construction waste, low quality sawdust and even broken glass as the main filler. This leads to the release of material of disgusting quality, which subsequently results in big problems during the operation of the structure.

Secondly, wood concrete has low protection against moisture. This, in turn, necessitates the obligatory wall cladding and the application of a protective finish to them.

The disadvantages include flaws in geometry.Compared to brick or foam block the deviation from standard sizes is quite large and can reach one and a half centimeters. This causes certain difficulties during construction. and requires careful selection of materials and high skill from the bricklayer.

You should also pay attention to the rather high price of wood concrete blocks, which is much higher than the cost of a foam block and aerated concrete.

The disadvantages include inability to use material for the construction of high-rise buildings, as well as the general instability of the material to aggressive gases.

When building an arbolite house in regions with a large amount of precipitation, it is necessary to equip a drainage system, and in the winter months to free the basement from snow. In this regard, the use of wood concrete blocks for the construction of basement walls, cornices and plinths is not recommended.

Views

The classification of wood concrete blocks occurs according to several criteria, the fundamental of which is the functional purpose of the material.

By this criterion there are two types of blocks: structural and thermal insulation... The category names speak for themselves. For example, the former are distinguished by a higher density, which can reach 850 kg per cubic meter, and are intended for the construction of external walls of low-rise buildings. The compressive strength of such products belongs to high classes B1.5, B2, B2.5 and B3.5, which corresponds to the M25, M35 and M50 grades, which include structures, in the design of which ST SEV 1406-78 is not taken into account.

Heat-insulating blocks have an average density of 500 kg / m³ and are used as an additional layer when arranging heat and sound insulation of buildings. The compressive strength indicators of such samples correspond to the classes B0.35, B1 and B0.75, which indicates that they belong to the M5, M10 and M15 brands without taking into account ST SEV 1406-78.

The second criterion for the classification of wood concrete blocks is the presence of additional fillers and a protective and decorative layer.

On this basis, three types of material are distinguished.

- Cladding blocks widely used for the construction of exterior walls. At the manufacturing stage, the front side of the blanks is covered with a cement-sand mortar, finished with facade tiles, or a coating of granite chips is formed. Outwardly, such wood concrete looks quite solid and beautiful, and the cement layer does not allow moisture to penetrate inside.

- Blocks made from dropout, compares favorably with traditional models made with wood chips. In such models, sawdust is thoroughly crushed on a special crusher, after which they are sorted from the remains of solid mechanical impurities and sieved. Such products are characterized by higher performance characteristics and are in high demand.

- Building models also have a protective layer on one side at least one and a half centimeters thick. As a facing, a cement-lime mortar is used, which, during the application process, is mixed with sand of high porosity. Such blocks are used as protective structures that help protect the metal elements of the building from corrosive processes.

And the last criterion by which the blocks are divided into types is the geometric shape of the products. On this basis, traditional and tongue-and-groove models are distinguished. And if everything is very clear with the first, then the second is a rather interesting design solution.

Such blocks are equipped with a "groove-comb" mount, which allows you to quickly erect interior partitions from them, assembling them according to the principle of a children's designer. The dimensions of such models are slightly different from the dimensions of traditional rectangular blocks and are 100x200x500 mm.

How to choose?

The main criterion for choosing a wood concrete block is to find a trusted manufacturer. The best option would be to purchase material from well-known companies present on the market. building materials for many years and valuing their reputation. This is due to the emergence of a large number of private industries, most of which violate the manufacturing technology and produce products that do not comply with GOST.

According to experts, half of all products entering the market do not meet the established requirements for one reason or another. Therefore, the purchase of high-quality material will be the key to successful construction and will not bring problems with the operation of the building in the future.

The main thing that you need to pay attention to when choosing wood concrete blocks is their price.

If the material is suspiciously cheap, then this means that inexpensive and possibly unhealthy components were included in its composition, so it is not worth purchasing such a product.

Very often, unscrupulous manufacturers replace wood chips of noble wood species with low-grade sawdust, as a result of which the cost of the material is noticeably reduced, while the quality leaves much to be desired.

The second thing that should alert the buyer is block heterogeneity. It shouldn't have multiple visible layers, as this can subsequently lead to delamination of the material.

You also need to pay attention to the violation of the geometric shape of the products. This usually happens when products are released on low quality equipment, as well as when using chips of different sizes.

You should pay special attention to the color of the blocks. A high-quality and completely dried product always has a gray color. If the material has green or brown shades, then this means that it was not dried well enough at the manufacturing stage. In addition, there should be no straw, twigs or leaves sticking out of the block. It is also better to refuse to purchase such material.

You need to look at void volumes - they should not exceed 3%... The block should look well knit and not loose.

And the last thing that you also need to pay special attention to is the length of the chips. As a rule, it is clearly visible in the structure of the material, and it will not be difficult to determine its average size.

For example, if there are many small elements in the block, this means that the reinforcing qualities of the chips are significantly reduced, and the strength of such material will be rather low. In order to somehow rectify the situation, many manufacturers significantly increase the share of cement, which is why the thermal conductivity coefficient of such a block increases significantly.

How to determine the number of pieces in 1 cube and pallet?

Before finding out the number of blocks in a cubic meter and a pallet, you need to explain why such information may be needed and what it can affect. First, such knowledge is required to calculate the optimal cost. Manufacturers indicate the cost of their products in different ways: someone names the price of one block, and someone - a whole cube or pallet.

Therefore, in order to navigate the prices it was easier, you need to know the exact number of blocks of different sizes in one cubic meter. For example, one cube of products with standard dimensions of 500 × 300 × 200 mm will contain 33.3 pieces, while the volume of each of them is 0.5x0.3x0.2 = 0.03 m³.

With a block size of 300x250x500 mm used for the construction of external walls, one cube will consist of 27 pieces, while in a cubic meter of material used for the construction of internal partitions dimensions 200x250x500 mm, there will be 40 pieces.

Secondly, knowing the exact number of blocks per cubic meter and pallet is necessary to calculate the amount of material required for construction. As for the number of blocks in a pallet, then with standard dimensions of 500 × 300 × 200 mm, it holds 48 pieces.

Owner reviews

Judging by the comments of the owners, wood concrete blocks are quite easy to use and practical to use.According to experts, the main working quality of wood concrete is that, while maintaining almost all the operational properties of wood, it is practically non-flammable, and building from it is much easier than chopping a house out of wood.

If we compare it with brick, then arbolite structures are much lighter and do not require the construction of thick meter-high walls. In comparison with reinforced concrete, wood concrete also wins: the audibility in houses made of reinforced concrete panels is several times higher than in houses built of wood concrete blocks.

In addition, many owners note the ability of wood concrete to independently maintain the necessary level of comfort in the room: it is not hot in such houses in summer, and not cold in winter.

Of the minuses, the high cost of the material and the impossibility of its use in the marine and subtropical climate are noted.

You will learn about the pros and cons of wood concrete blocks in the next video.

The comment was sent successfully.