Choosing a stud anchor

At construction sites, in the manufacture of structures, there is always a need to fix something. But the usual type of fasteners is not always suitable, when concrete or other durable material acts as the base. In this case, the stud anchor has shown itself well. In this article, we will consider the features of this device.

Characteristic

The anchor-stud (wedge) consists of a threaded rod, at the end of which there is a cone, a spacer cylinder (sleeve), washers and nuts for tightening. It is a widely available and widely available product. Their assortment is quite wide. Zinc-coated carbon steel products are most commonly seen on the shelves, but stainless steel anchors can also be seen.

Anchor rod is one of the important details in construction work. Their reliability and the required amount significantly affect the strength and safety of building structures.

All products of this type were previously manufactured in accordance with GOST 28457-90, which became invalid in 1995. No replacement yet.

This type of mount has numerous advantages:

- the design is very simple and reliable;

- excellent bearing capacity;

- high speed of installation, no special skills are required for installation;

- widespread, you can always find the right option;

- affordable price.

There are also disadvantages, and they are as follows:

- due to the design features of the product, it is not recommended to use it in soft materials (wood, drywall);

- it is necessary to observe high accuracy when drilling holes;

- after dismantling the product, it will no longer be possible to use it the next time.

Varieties

There are several varieties of this type of fastening systems for solid bases, such as spacer, spring, screw, hammer, hook, frame. Their main purpose is to attach various objects to a concrete or natural stone base. You can also find a threaded rod collapsible anchor, it is mainly used for anchoring in suspended ceilings or hollow partitions.

Anchors are not very suitable for installation in wood, since when screwed in, they violate the structure of the wood, and the reliability will be very small. In some cases, when it is required to fasten boards for formwork, anchors with a replaceable spring are used.

All products can be divided into 3 subgroups according to the material of manufacture:

- the first is made of galvanized steel, it is recommended for installation in concrete;

- the second is made of stainless steel, it does not require any coating, but this group is very expensive and is made only by prior order;

- in the production of products of the third group, various alloys of non-ferrous metals are used, the parameters of the products are determined by the characteristics of these alloys.

There are also additional properties. For example, reinforced studs with increased tensile strength can be produced.

There are 4-petal systems that have increased resistance to twisting. But these are all modifications of the classic stud anchor.

Dimensions and markings

Basic dimensions of stud anchors:

- thread diameter - from 6 to 24 mm;

- anchor diameter - from 10 to 28 mm;

- length - from 75 to 500 mm.

More details can be found by examining the relevant regulatory document. The most commonly used sizes are: M8x75, M10x90, M12x100, M12x115, M20x170. The first number indicates the thread diameter and the second indicates the minimum stud length. Non-standard products are manufactured according to TU.To fix the formwork when concreting the base, it is possible to use M30x500 hardware.

Threaded anchors M6, M8, M10, M12, M16 are the most common. They have a very large expansion area, they securely fix the required items.

To decipher the marking of anchor bolts, you should know that first the type of material (steel) from which the product is made is indicated:

- HST - carbon steel;

- HST-R - stainless steel;

- HST-HCR is a corrosion resistant steel.

Following is the type of thread and the length of the hardware itself. For example, HST М10х90.

How to choose?

There is no universal fastener, so you need to select wedge anchors based on the following conditions:

- size (thickness of the part that will be attached to the base, and the depth of immersion of the anchor into it);

- how it will be located (horizontally or vertically);

- calculate the expected loads that will affect the hardware;

- the material from which the mount is made;

- the parameters of the base into which the stud anchor will be installed.

Also, before buying, you need to check the documents and certificates of conformity for products. This must be done because anchors of this type are used in the installation of important structures, and not only the integrity of these elements, but also the safety of people, largely depends on their reliability.

How to twist?

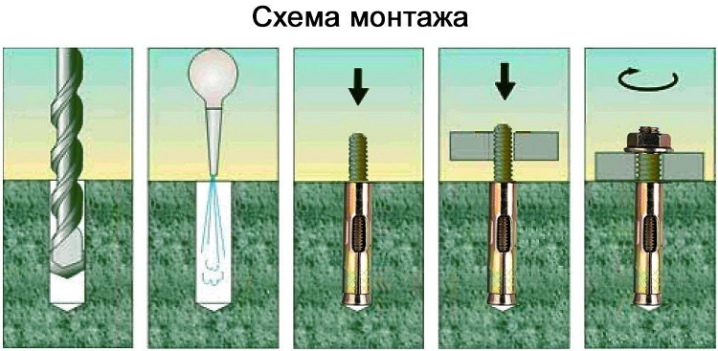

Installation of the stud anchor is no different from the installation of other types of these hardware or dowels.

- First you need to drill a hole in strict accordance with the diameter of the fastener. Then remove material crumbs and dust from the recess. Thorough cleaning is not required.

- After completing these operations, an anchor is installed in the prepared place. You can hammer it with a mallet or hammer, through a soft gasket, so as not to damage the product.

- At the end, connect the anchor stud with the attached object. For this, a special nut is used, which is present in the design of the product. When it twists, it opens the petals in the locking cylinder and locks into the recess. In this case, the required item is securely attached to the surface.

When installing a wedge-shaped anchor, the tightening torque of the nut is of great importance. It is very important to tighten the nuts correctly. If you do everything right, then later the mount will serve for a long time and reliably.

The main points to pay attention to during installation.

- Insufficient tightening of the nut will cause the cone to enter the spacer sleeve incorrectly, as a result of which the fasteners will not take the desired position. In the future, such fastening may weaken, and the entire structure will become unreliable. But there are times when the stud anchor still achieves maximum firm fixation in the material, but already with an offset from the desired position.

- Overtightening the nut also has a negative effect. If tightened too much, the cone fits too tightly into the expansion cylinder. In this case, the base, into which the stud anchor enters, may collapse. This can happen even before the force begins to act on the hardware.

Not all workers are aware of the possible dangers associated with non-observance of the tightening rules. It is very important to control how tight these fastening systems are. There is a special tool - a tightening control module, with which you can adjust the forces. He is able to document his actions for subsequent checks.

In the next video, you will find examples of the installation of various anchors.

The comment was sent successfully.