Choosing frame anchors

Frame anchor - fasteners designed to connect the frame structure (primarily windows or doors) with the main wall material (brick, concrete, etc.). Structurally, this fastener is close to other, so-called anchor dowels, but it has a number of differences. The article will consider the features of frame fasteners.

Peculiarities

The main differences between a frame anchor and any other anchor type fasteners are elongated pin with countersunk taper head... All this is necessary in order to be able to fix the volumetric structure of a window frame or door jamb to the usually full-bodied wall material. The fasteners are excellent for the installation of hollow structures, such as modern frames of metal-plastic windows or jambs of metal doors.

The task of fastening is to securely fix the frame in the opening... Since such structures, in addition to constant loads, constantly experience variable dynamic effects (arising from their functionality), special requirements are imposed on the fasteners intended for their installation. It must be strong against tearing and bending, while tolerating vibration.

It is for this reason that the popular expansion plugs with a polyethylene or plastic sleeve are unacceptable. Over time, plastic can collapse precisely due to changing vectors of application of forces.

The metal anchor bolt and the spacer sleeve make it possible to combine all the requirements for such a fastener, which has significantly expanded the scope of application of frame anchors. Currently, they are purchased not only for installing a window or door, but also for installing various kinds of structures, decor or hanging not very heavy equipment.

The emergence of frame anchors has caused the need for their standardization, as a rule, they correspond to TU, since during the development of GOSTs such fasteners did not exist at all. But the alloy (steel, stainless steel, brass, aluminum) used for their manufacture must strictly comply with GOST, according to which the products of metallurgical enterprises are standardized.

Dimensions (edit)

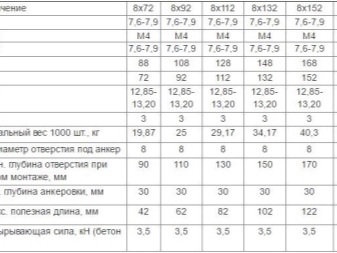

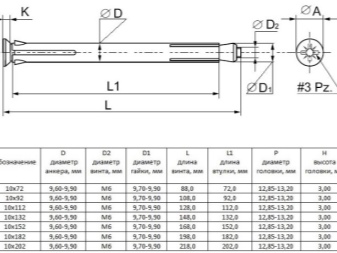

In addition to the material from which the frame fasteners are made, its size - length and diameter - is also subjected to standardization. Due to the peculiarities of the fastening, in which metal tabs are formed that wedge the fastener, it cannot be too short. Wedging in the immediate vicinity of the surface of the material - it doesn't matter whether it is brick or concrete - can cause its destruction and, accordingly, the connection loses its main properties. This is most relevant, of course, for brick structures. It is for this reason that the minimum length is 72 mm.

Dowels of this length are available in two standard diameters: 8x72 mm and 10x72 mm. The first sample can withstand a standard 30 kg for fracture, and the second is designed for the installation of heavier structures. The least long anchor dowel is designed for the installation of non-frame structures, has a modest size of 10x32 mm; This product is quite rare, since the tasks for which it was developed are successfully solved with cheaper fasteners with a plastic or polyethylene sleeve.

The following size group has a standard length of 92 mm. Accordingly, it is possible to purchase anchors 8x92 mm and 10x92 mm, depending on the effort to which this fastener must resist.It is very problematic to use the first two size groups for the installation of window frames or door jambs due to their small length, part of which will be covered by the most mounted frame structure. Their area of application is somewhat different: facade elements, decor, non-hollow structures of small thickness. Dowels with a length of 100 mm or more can be considered as frame ones. They are also divided into two groups depending on the diameter: 8x100 mm and 10x100 mm.

The next standard size group with the same diameters has a length 8х112 mm and 10х112 mm. Such anchors are quite suitable for the installation of standard window structures, and if they do not have opening sashes, this fastener can be considered ideal.

In the case when the size of the structure is larger than the standard, and even at the same time, large sashes are mounted in it, which seriously affect the center of gravity when they are opened, you will have to choose elongated anchors: 8x132 mm and 10x132 mm... They can also be considered minimal when installing metal doors. In the family of frame fasteners there are also real "monsters" used in the installation of structures of large mass and size: 8x152 mm and 10x152 mm.

The first ones are quite rare, since products of this length are used mainly for large-sized structures that are heavy, the reinforced version of fasteners is still more popular with users. Very specific anchors are also rare. 10x202 mm.

Not all manufacturers include large-sized products in their assortment, as they are less popular.

How to choose?

When choosing frame anchors, one should proceed from the tasks that need to be solved. If the fastener involves little effort, it is hardly worth paying extra for reinforced and elongated anchors, which can be much more expensive. Of course, you should pay attention to the material from which the fasteners are made. Brass can serve well in an aggressive environment, especially in high humidity, but it has little strength. The same pros and cons of aluminum fasteners.

Galvanized steel remains the most popular material, but it also corrodes and is unlikely to last long in high humidity conditions. Stainless steel has proven itself well. But with all the positive qualities of a product made of it, it is much more expensive. As you can see, the choice of the material from which the anchor should be made is not at all an easy matter.

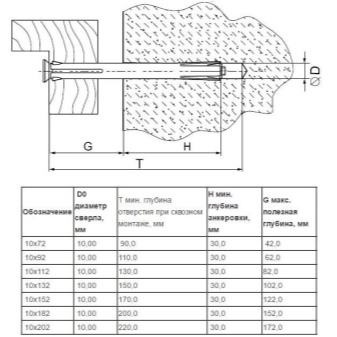

It is important to study the products presented in the store before purchasing and installing. Pay particular attention to the spacer sleeve.

If its walls are less than 0.8 mm thick, most likely, such fasteners will not be able to create sufficient resistance when installing windows, and even more so door jambs. Being wedged in a hole inside a solid material, under the action of the applied forces, the sleeve is deformed or even destroyed, which can have very unpleasant consequences, up to the collapse of the mounted structure.

Particular care should be taken when selecting fasteners for incomplete materials. So, the anchor for hollow bricks cannot be short, it is better to choose the maximum length. In addition, such a dowel should have several spacer zones. The same requirements apply when selecting fasteners for aerated concrete. Anyway, if the material is in doubt, it is better to purchase fasteners in specialized stores, where there is an opportunity to get expert advice.

How to fix it?

To install a frame or door jamb, in addition to a set of anchors, you cannot do without some tools:

- hammer drill with a set of drills for drilling wall material and for drilling a hole in a metal structure;

- hammer;

- Phillips screwdriver or a corresponding bit for installation on a screwdriver, some craftsmen manage with the same perforator in drill mode at low speeds;

- building level;

- pencil.

Fixing the frame with anchors step by step looks like this.

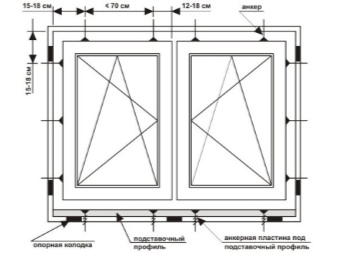

- The frame must be wedged in place, be sure to adjust the vertical and horizontal level. Wedges can be made of wood or plastic. You will need a hammer to install them.

- Frame marking for holes... It is customary to drill at a distance of 30 cm from the corners, but this is not an unshakable truth, sometimes you have to take into account the features of the wall and change the standard distances, as a rule, this does not affect the quality of the frame installation. In the places chosen for drilling, it is necessary to make a sweep for the anchor head.

- In designated places holes drilled... Further, after changing the drill, it is necessary to drill the wall material to a depth sufficient to install the fasteners.

- Drilled hole clean by removing debris, dust and debris.

- Insert the anchor into the drilled hole. You may have to use a hammer, this should be done without undue effort.

- Using a Phillips screwdriver or bit tighten the anchor.

- When installing the next anchor check the position of the frame with a level - if no displacement has occurred, do all the operations described above.

For the installation of a small non-swing frame with a side of less than 1 m, 4 dowels are sufficient. Usually, two anchors are used to install frames on each side of the frame.

Non-standard frames of great length or height require more anchors.

In the next video, you will find examples of the installation of various anchors.

The comment was sent successfully.