Everything you need to know about brass anchors

Sometimes, during construction or renovation, it is required to attach a structure to the wall or hang it from the ceiling. In this case, you need to think carefully about the installation method, because ordinary nails or screws will not always be able to hold a heavy object. Today, brass or drop-in anchors are used for this purpose. Thanks to them, you can not be afraid that the suspended object will fall on your head.

Description

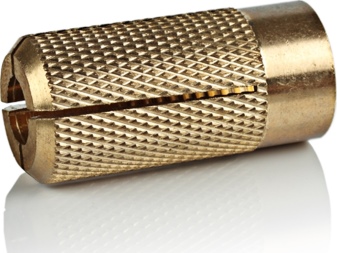

The brass anchor, or collet, is a fastening element in the form of a sleeve with an internal thread and notches on the outside, designed for mounting objects to walls, steep surfaces and ceilings. Outwardly, the product resembles a drive-in anchor made of carbon steel, but differs from it in some operational characteristics. The collet is made of brass. It is a multicomponent alloy based on non-ferrous metals - copper, zinc and tin. Together, they are superior in quality to steel.

Brass products are more reliable, although they have less strength than steel. They are resistant to mechanical wear, corrosion and oxidation processes, as well as high temperatures, flame and pressure. Unlike steel, brass has a higher density - up to 8500-8700 kg / m3 compared to 7700-7900 kg / m3 for steel, therefore it has a greater weight.

These qualities determine the price of brass products, which is usually 1.5, and sometimes 2 times higher.

The brass anchor is capable of holding heavy structures for a long time. The installation process is simple and does not require special skills or knowledge, which is determined by the simple design of the product. The outer surface of the sleeve has many notches, although smooth models are also available on the market. They provide better grip of the collet with the base material and do not allow it to rotate during installation.

Mounting is possible due to the presence of threads on the inner surface and several slots in the rear, which form the spacer shafts. The thread is required to screw in a bolt, stud or screw and secure the structure.

The sleeve has a through hole. In the spacer part, it tapers in the form of a cone. During installation, the fastening element enters the sleeve and forces the tabs to diverge to the sides. The softness of the alloy allows the screwed-in steel bolt to wedge the product with ease. This ensures reliable fixation of the anchor in the hole.

Applications

The main purpose of the product is to fasten light and medium-heavy structures to concrete, natural stone, granite and solid bricks. With the help of brass anchors, structures can be installed both indoors and outdoors. The special design and good technical characteristics of the product make it possible to use it in areas with difficult operating conditions.

Collet fasteners are used in structures when it is impossible to do with ordinary plastic dowels. They securely hold heavy and bulky items. For example, in private construction, a brass collet is useful for hanging items, installing shelves, consoles, racks, wall and ceiling rails, vertical stairs and horizontal bars. With their help, it is possible to install cornices, suspended ceilings and wall panels.

Brass is resistant to mechanical wear and corrosion, which gives additional advantages of its use. The product has a strong adhesion to the material of walls and ceilings, so the builder can not be afraid of water vapor getting there and their condensation.

Varieties

Brass anchors are available in various sizes today. The main manufacturers are Fisher (Germany), Mungo (Switzerland) and Sormat (Finland). Please note that there are their Chinese counterparts, the reliability of which should not be relied on.

All products have the same shape and technical characteristics, but are designed for different loads. Before installation, it is necessary to calculate its actual value and compare it with the permissible norm.

Note! The structure will be considered reliable only if the safety margin of the split anchor is 3-4 times higher than the expected load.

Manufacturers produce products in one piece, without using welding or soldering, which significantly increases their mechanical strength. Additional fixation in the base material will be provided by notches on the surface of the collet fasteners - they will help to secure the spacer lugs more strongly and prevent the product from scrolling during installation.

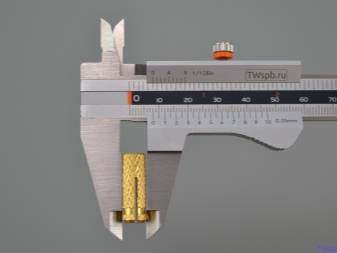

The brass collet is named after the thread size. There are products on sale with the following parameters:

- M4 (5x16 mm);

- M5 (6x20 mm);

- M6 (8x24 mm);

- M8 (8x30 mm);

- M10 (12x34 mm);

- M12 (16x40 mm);

- M14 (20x42 mm);

- M16 (22x44 mm).

The packaging always indicates the size of the thread of the anchor. Official manufacturers duplicate it on the sleeve, so pay attention to the engraving of each part to distinguish it from a fake. By other criteria, it is almost impossible to determine the original, you will probably find out about this during operation.

The numbers in brackets indicate the dimensions of the product: the first is the diameter of the anchor, the second is its length. Sometimes they are indicated together with the size of the thread, so do not be intimidated by the designation, for example, M8x30 - the manufacturer thus reminds you of the length of the fastener.

Installation features

For high-quality fastening of the structure, it is necessary to sequentially perform the following steps:

- prepare a hole corresponding to the outer diameter of the collet;

- clean the hole from construction debris;

- insert the collet and hammer it with a hammer with a few light blows;

- screw the bolt, stud or screw of the item to be installed into the anchor.

On a note! The diameter of the hole in the base should correspond to the diameter of the anchor, and the depth should be 3-5 cm greater than the length. Such a margin must be made in order for the screwed-in bolt to fully fit the anchor.

The collet must be driven to its full length. Do not worry that the fasteners may go deeper: when hammering in with a hammer, the anchor will partially open the legs, additional fixation will be provided by the notches.

To dismantle the structure, it is necessary to slightly loosen the fastener so that the spacer legs of the collet return to their original position. You do not need to completely unscrew the bolt; you should leave the collet with it. Then, holding the anchor with pliers, you can unscrew the part.

Using such a universal fastener will save you the need to install supporting supports and stiffening ribs. Installation does not require much effort, so even inexperienced builders can use the products. The result is a reliable and durable mount at an affordable price that will last you for years.

For everything you need to know about brass anchors, see the video below.

The comment was sent successfully.