Overview of Hilti anchors

Installation of various structures requires the use of all kinds of fasteners. Anchors are a reliable option. They represent a detail that looks like a small anchor. Such models are more often laid in durable and hard surfaces. Today we will talk about anchors manufactured by the manufacturer Hilti.

Peculiarities

Hilti anchors have a huge range of possibilities. They are used to secure massive surfaces with significant mass. Models will be the best option for mounting various bases, including aerated concrete, drywall, brick and concrete structures.

Anchors of this brand can have different technical characteristics. Each separate type is used for different materials. Samples can have all kinds of sizes and thicknesses, so in the range of products, any user will be able to find a suitable variety for him.

The brand produces various modifications of fasteners, including frame, wedge and driven models.

Range

The Hilti brand is today one of the largest manufacturers of construction fasteners, including anchors. The most common options include the following types.

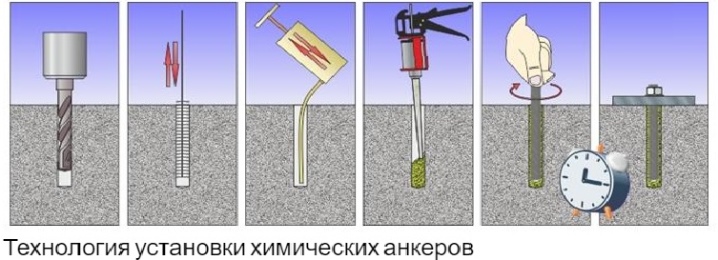

Chemical

These models are distinguished by the fact that they are equipped with a special adhesive, which is used for a strong hold. Most often, chemical anchors are used to fix hollow bricks, limestone, shell rock and expanded clay concrete. Chemical types will be the best option for anchoring materials with a porous structure. But at the same time, the replacement of such elements, if necessary, will be quite difficult, since the integrity of the base will have to be violated.

Currently, chemical varieties are available in several versions. So, there are special capsules, which are small full containers with an adhesive composition. Most often they are made from durable polyethylene. Their size may be different. In contact with a metal dowel, this container is quickly depressurized and, under the influence of air currents, mixes and hardens enough, and this leads to a strong fixation of the parts.

The use of such containers allows us to make the fastening process as fast and simple as possible. But the cost of such chemical varieties will be much higher compared to other options. In addition, each container is strictly metered. Most often they are available in containers of 300 or 500 milliliters.

The capsules can be used in areas prone to corrosion.

Also, special injections can be attributed to the chemical variety. They are small two-volume ampoules. One of them contains an adhesive mass, the other contains a special hardener for the composition. The injections can be sold in different quantities. They have a lower cost compared to the previous type. But at the same time, to work with such fasteners, you need to buy special construction tools separately.

The containers are filled into special hand-held apparatus. By clicking on them, through the dispenser, you will receive an adhesive composition. If you regularly carry out various installation work, then it is better to use a special pneumatic dispenser. Chemical varieties quickly replaced the standard plugs. They do not have unpleasant odors.All chemistry that is used for the formulations is safe for humans and their health.

Capsules and injections make it possible to secure both heavy structures and lightweight products.

Mechanical

These clamps are also widely used in installation work. They can be used for joining massive materials with high, medium weight, as well as for creating various insulation systems. Hilti mechanical anchors can be used for virtually any recess shape. They can also be suitable for substrates that have a grainy structure. They are also taken to strengthen load-bearing structures. Spacers are often manufactured from carbon steel with a zinc coating to protect against corrosion.

If you will use anchors for the installation of light structures, then it is recommended to use them together with self-tapping screws. Often they are fixed in combination with front fasteners. Such models of fasteners are quite easy to install, if necessary, they can be easily removed from the structure. Retainers of this type can boast a special level of resistance to almost any mechanical and chemical damage. They are made exclusively from high-strength metals and their alloys.

Expansion anchors also have increased impact resistance. During installation, they are almost impossible to bend or break. During manufacturing, they are covered with special protective coatings that do not allow them to collapse due to a large amount of moisture. Mechanical anchors can be used in conjunction with specialty chemicals designed to produce composite joints in materials that have cracks or large gaps.

The product range of this brand also includes special mechanical fasteners-studs (HILTI HST). They can be used for any materials that will be subjected to heavy loads during operation.

So, they are often taken to create durable floors, roofing. In these cases, the use of chemical varieties is not possible.

Wedge stud fasteners have a high level of strength and wear resistance. They are assembled into the material only with the special HS-SC tool. If you need to carry out the installation in the shortest possible time, then the use of other devices is not allowed. These anchors are able to withstand any negative weather conditions. They are available in different diameters (M10, M16, M30, M12).

The brand also produces special HILTI HSA anchors. They are also designed to connect massive structures of great weight. These products are available in diameters M6 and M20. Fasteners are often made of stainless steel with a galvanized finish for protection.

The brand specializes in the production of drop-in anchors (HKD). These fasteners are manufactured from tough zinc-plated carbon steel. Often these models are used for concrete with gaps or cracks.

Drop-in anchors of this brand can have a length ranging from 25 to 80 millimeters.

These connections are best used for hard and durable thick concrete substrates. The size of the internal thread can be from 6 to 25 millimeters.

Advantages and disadvantages

Anchor bolts manufactured by Hilti offer a number of important and significant advantages.

- High quality. The products of this company allow you to create strong and durable connections. Moreover, they will not collapse under chemical, mechanical or atmospheric influences.

- Convenient transportation. Such anchors are small and lightweight. They are easy to transport, open containers with chemical compositions can be stored in this form for one year, for transportation they can simply be slightly covered with a lid.

- Convenient installation. Anyone can fix this fastener. Their installation does not require any special knowledge.In addition, along with such anchor bolts in one set, there must be a detailed instruction for use, which describes how to carry out the installation step by step.

- Reliability. With sharp temperature changes, chemical models will not expand or contract, they will retain their consistency, will not lose their properties, and will be able to provide a reliable connection.

But the products of this manufacturing company also have some drawbacks. So, many point out the too high cost of these anchors. First of all, this applies to chemical capsules with glue. But at the same time, we can also say that the quality of the joints created with their help will fully correspond to the price of the product.

Also, as a disadvantage, one can single out too long hardening duration. This disadvantage applies to chemical samples. It sometimes takes too long for them to become completely solid, which leads to significant installation time.

In addition, it takes a significant amount of time to dissolve the hardener with the adhesive mixture itself.

Selection Tips

When buying anchors, you should take into account some important selection criteria. So, it is necessary to take into account what material the selected models are intended for. To connect aerated concrete, concrete, brickwork, it is better to give preference to strong mechanical samples that can withstand significant loads. Such elements will make the fastening strong enough. For lighter and larger elements, different types of chemical liquid anchors can be used.

When choosing such retainers, their cost also plays an important role. Chemical capsules are the most expensive. The injections cost much less, but at the same time, to use them, you will need a special gun with a dispenser, which will have to be purchased separately. Mechanical varieties are the most affordable options. In addition, they do not require additional mounting parts (apart from some stud models).

When purchasing anchor bolts, it is better to look at the material from which they are made. The best option would be steel (carbon or alloy). Parts made of this metal have a high level of strength, resistance to chemical and mechanical stress.

Check the coating of each anchor. Traditionally, they are coated with a special zinc compound. If the fastener is released without a protective material, then it can quickly lose all its important properties, become covered with a layer of corrosion, which will lead to further destruction of the connection made. Before buying, make a decoding of the marking of the anchors.

It should include the values of the maximum thickness of the material to be attached, the level of resistance to corrosion. Also here you can find the diameter of the anchor bolt, the total length of the product.

Usage

In order for the anchor fasteners to be able to provide the most durable and reliable connection of the material, you should adhere to some important installation rules. Each individual model has its own mounting technology. If you plan to work with substrates that have porous structures, then the installation should start with filling the mesh sleeve in the pre-drilled recess. In this case, it is recommended to drill with a diamond tip. This will make the surface smooth and even after processing.

Then a little binder should be applied to the surface of the sleeve. In this case, the hole must be 2/3 filled. It is slightly pressed in together with turning the threaded rod (then the necessary element will be screwed to it). After the substance has solidified, the composition will provide a strong connection.

All the holes into which the clips will be inserted are thoroughly cleaned of various debris beforehand.The surface must be absolutely clean. After that, the recess must also be blown out with compressed air; for this, you can use a special pump.

If you are using a chemical capsule for joining, then it must be placed in a pre-made recess. One container is designed to hold only one piece.

Such options can be used for materials with a high level of strength and hardness.

The capsule is sharply pressed with a special hairpin, after which the hardener will begin to pour out of the container. It will enter into a chemical reaction with the adhesive itself. To make the consumption of the substance in the cartridge more economical, you can use the calculator of the required amount of injection mass. This allows for a slight reduction in installation costs.

Review of the Hilti HFX model in the video.

The comment was sent successfully.